Marine concrete, marine concrete impermeable agent, and preparation method and application thereof

A technology of marine concrete and anti-seepage agent, applied in the field of concrete anti-seepage agent, can solve the problems of inorganic coating and concrete adhesion, poor toughness, anti-aging, poor anti-wear ability, and reduce the workability of concrete. Achieve good impermeability and long-term mechanical properties, simplify the construction process, and improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

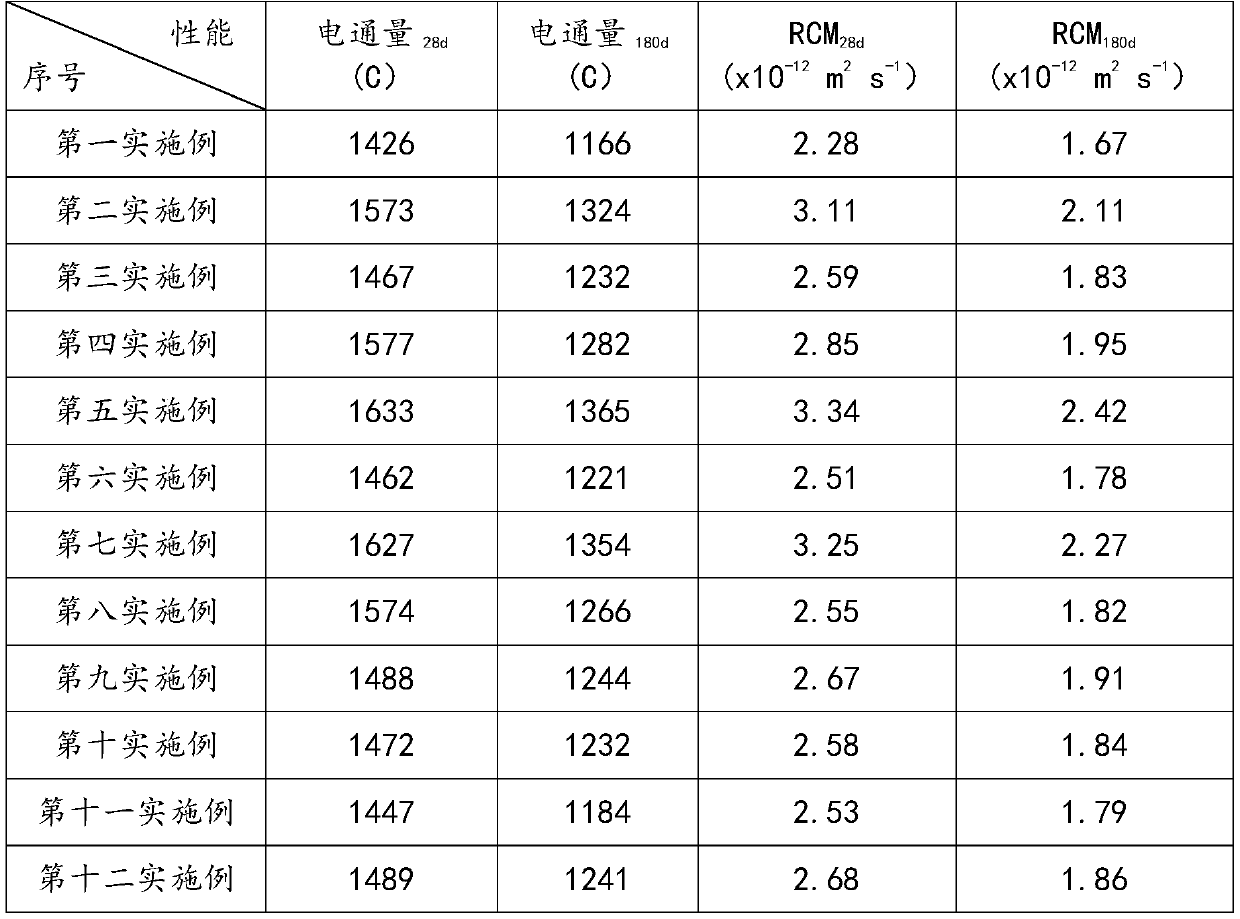

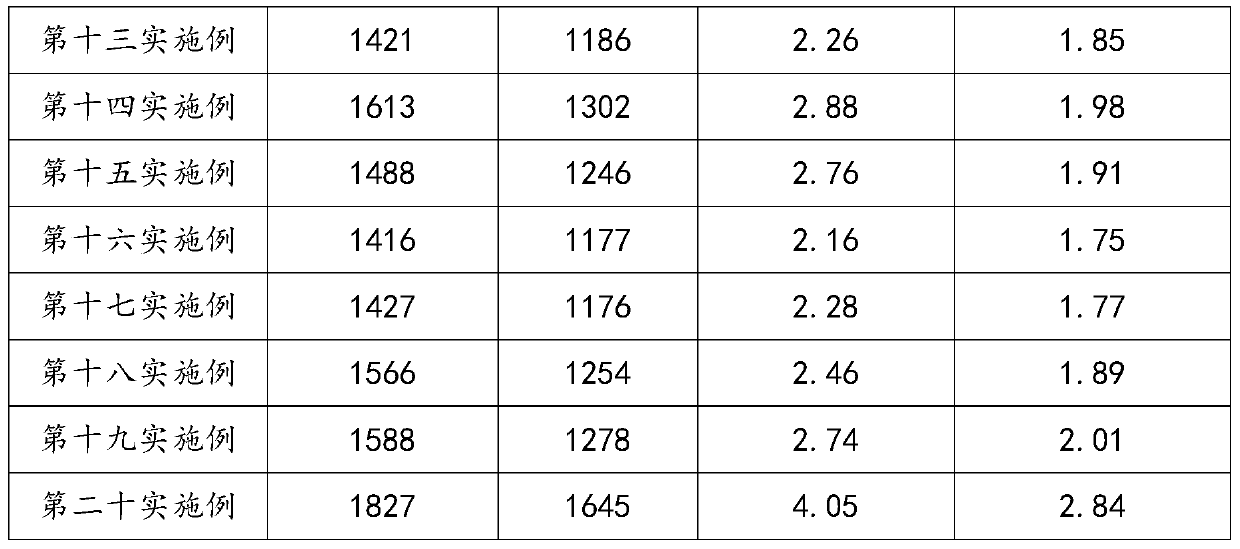

Examples

no. 1 example

[0034] A marine concrete with good anti-seepage performance comprises C40 concrete and a marine concrete anti-seepage agent. In terms of mass percentage, the C40 concrete is composed of 22% cement, 40% gravel, 28% sand, 0.6% water reducing agent and 9.4% fly ash. -2006 "Standard requirements for concrete sandstone.

[0035] In terms of mass percentage, the marine concrete anti-seepage agent consists of 40% Portland cement clinker (particle size 1.18-2.36mm), 35% high iron sulfoaluminate cement clinker (particle size 2.36-4.75mm) and 25% Composition of dicalcium perburned silicate (particle size 0.6-1.18mm). The dosage of the marine concrete anti-seepage agent is 17% of the cement mass in the C40 concrete. All components of the anti-seepage agent were purchased from Shandong Zibo Huayin Special Cement Co., Ltd.

[0036]Mix the components of this example and the C40 concrete directly in a mixer, add water with a water-cement ratio of 0.32, mix evenly, and prepare the samples ...

no. 2 example

[0038] A marine concrete with good anti-seepage performance comprises C35 concrete and a marine concrete anti-seepage agent. In terms of mass percentage, the C35 concrete is composed of 18% cement, 38% gravel, 30% sand, 0.6% water reducing agent and 13.4% fly ash. -2006 "Standard requirements for concrete sandstone.

[0039] In terms of mass percentage, the marine concrete anti-seepage agent consists of 44% Portland cement clinker (particle size 1.18-2.36mm), 46% high iron sulfoaluminate cement clinker (particle size 2.36-4.75mm) and 10% Composition of dicalcium perburned silicate (particle size 0.6-1.18mm). The dosage of the marine concrete anti-seepage agent is 17% of the cement mass in the C35 concrete. All components of the anti-seepage agent were purchased from Shandong Zibo Huayin Special Cement Co., Ltd.

[0040] Mix the components of this example and the C35 concrete directly in a mixer, add water with a water-cement ratio of 0.33, mix evenly, and prepare the sample...

no. 3 example

[0042] A marine concrete with good anti-seepage performance comprises C40 concrete and a marine concrete anti-seepage agent. In terms of mass percentage, the C40 concrete is composed of 22% cement, 40% gravel, 28% sand, 0.6% water reducing agent and 9.4% fly ash. -2006 "Standard requirements for concrete sandstone.

[0043] In terms of mass percentage, the marine concrete anti-seepage agent consists of 15% Portland cement clinker (1.18-2.36mm in particle size), 52% high iron sulfoaluminate cement clinker (2.36-4.75mm in particle size) and 33% Composition of dicalcium perburned silicate (particle size 0.6-1.18mm). The dosage of the marine concrete anti-seepage agent is 17% of the cement mass in the C40 concrete. All components of the anti-seepage agent were purchased from Shandong Zibo Huayin Special Cement Co., Ltd.

[0044] Mix the components of this example and the C40 concrete directly in a mixer, add water with a water-cement ratio of 0.32, mix evenly, and prepare the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com