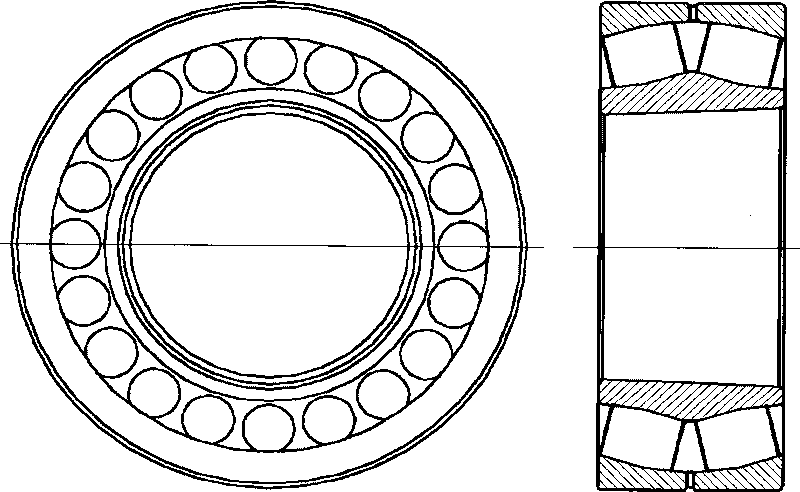

Sliding bearing of roller presser

A sliding bearing and roller press technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as affecting the overall performance of the equipment, reducing the service life of bearings, and limiting the large-scale development of equipment output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

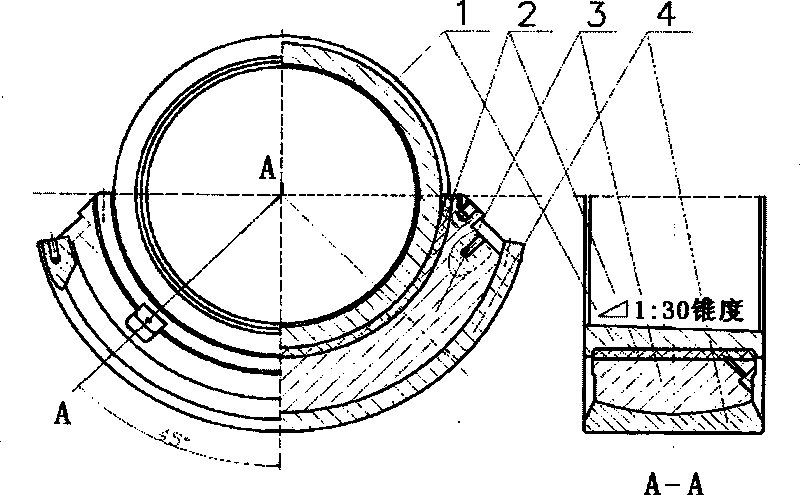

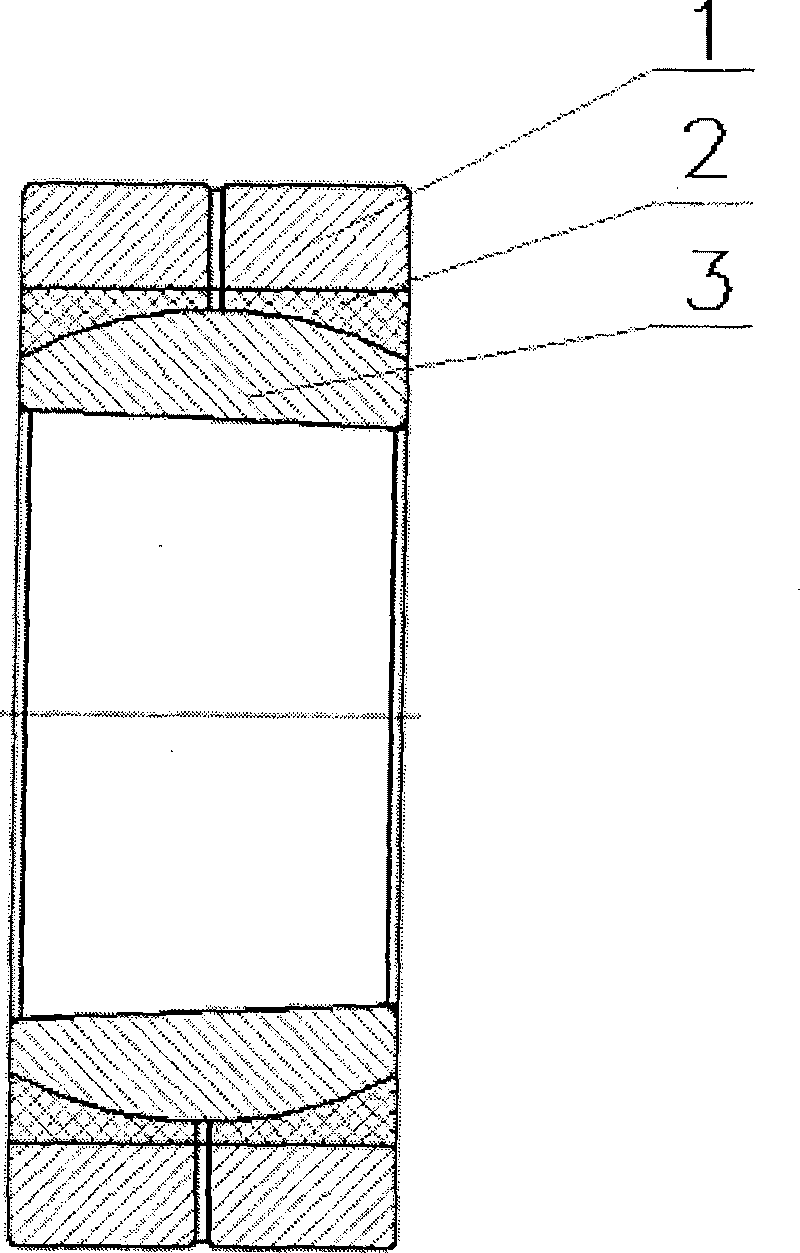

[0004] Because the sliding bearings processed from traditional sliding bearing materials such as platinum alloys and bronze alloys have high requirements for equipment processing and use, maintenance is difficult, and the manufacturing cost of bearings is also high, making it difficult to realize. In view of this feature, the present invention adopts zinc-based alloy ZA303 as the bearing material, which solves the above-mentioned technical problems. It is possible to use sliding bearings instead of rolling bearings in this kind of equipment. While retaining the self-aligning performance of the original equipment using rolling bearings, the present invention greatly improves the bearing capacity of the bearings and satisfies the maximum Equipment use requirements, with the interchangeability of the original design. The present invention solves the problem of the bearing capacity of the bearing; prolongs the service life of the bearing, thereby improving the performance of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com