Hydrated calcium aluminosilicate nano crystalline nucleus early strength agent and preparation method thereof

A calcium aluminosilicate and nanocrystalline technology, which is applied in the direction of silicate and aluminum silicate, can solve the problems of poor compressive strength improvement, large particle size, and easy agglomeration, so as to improve early hydration and mechanical properties. Behavior, simple preparation process, effect of increasing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The first aspect of the present invention provides a preparation method of calcium aluminosilicate hydrate nano crystal nucleus accelerator, comprising the following steps:

[0014] Add the aqueous solution of the calcium source, the aqueous solution of the silicon source and the aqueous solution of the aluminum source dropwise into the polycarboxylate water reducer dispersion liquid, adjust the pH to 10.0-13.5, and carry out the stirring reaction to obtain the calcium aluminosilicate hydrate nanocrystalline nucleus Early strengthening agent.

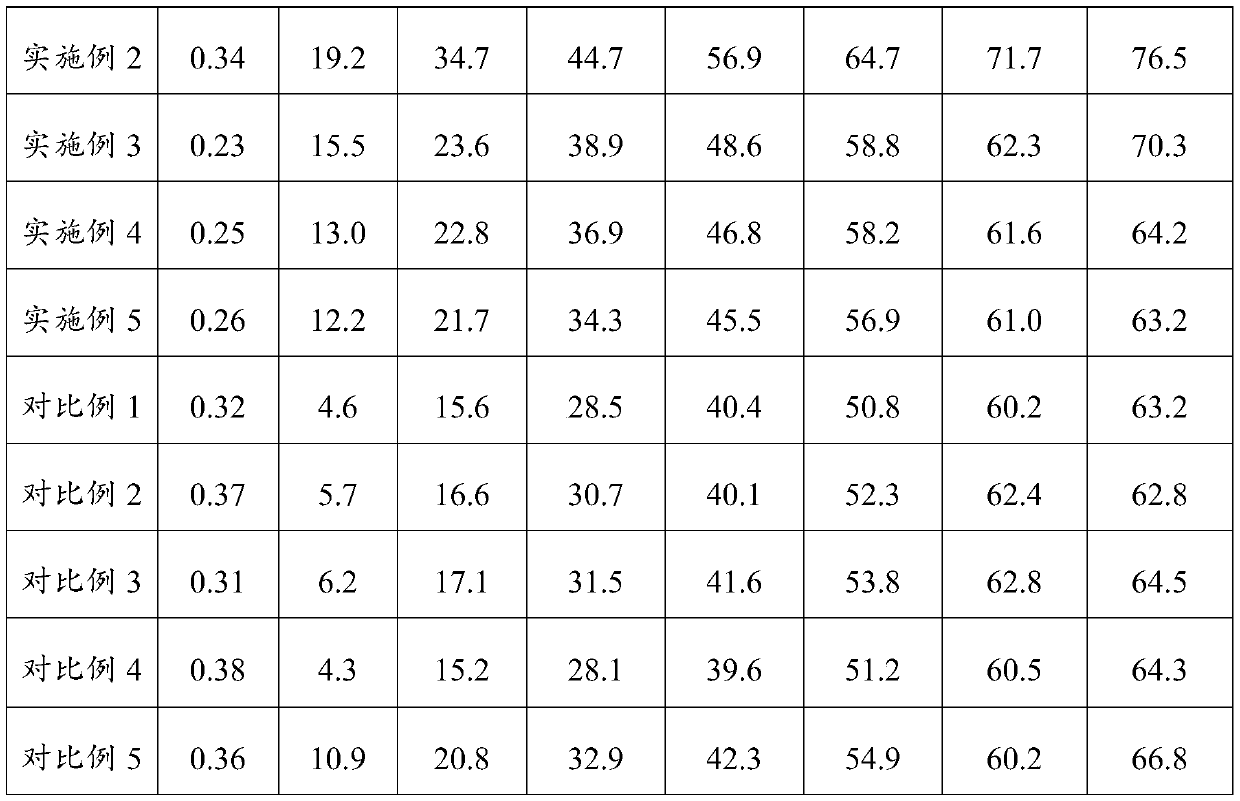

[0015] The applicant found that when synthesizing the calcium silicate hydrate nanocrystal nucleus, introducing a certain amount of aluminum salt can form an aluminum oxide tetrahedron as a bridging oxygen tetrahedron in the molecular structure of the calcium silicate hydrate, and promote the production of polycarboxylate superplasticizers. The adsorption capacity, thereby enhancing the steric hindrance of polycarboxylate superpl...

Embodiment 1

[0034] This embodiment provides a preparation method of calcium aluminosilicate hydrate nanocrystal nucleus accelerator, comprising the following steps:

[0035](1) Pre-configure 20ml of calcium nitrate solution with a molar concentration of 2mol / L, 20ml of a sodium silicate solution with a molar concentration of 2mol / L and 20ml of an aluminum nitrate solution with a molar concentration of 0.06mol / L, and place it at 20°C In the constant temperature water bath box, after the temperature is stabilized, it is ready for use; wherein, the calcium-silicon molar ratio is 1.0, and the aluminum-silicon molar ratio is 0.03;

[0036] (2) Configure 100ml of polycarboxylate superplasticizer dispersion with a mass fraction of 6.0%, and stir with a magnetic stirrer for 30min at a water bath temperature of 20°C;

[0037] (3) The above-mentioned polycarboxylate water-reducer dispersion is used as the bottom liquid, and the pH value is adjusted to 11.0 with a mass fraction of 30% sodium hydroxi...

Embodiment 2

[0039] This embodiment provides a preparation method of calcium aluminosilicate hydrate nanocrystal nucleus accelerator, comprising the following steps:

[0040] (1) Pre-configure 20ml of calcium nitrate solution with a molar concentration of 2mol / L, 20ml of a sodium silicate solution with a molar concentration of 2mol / L and 20ml of an aluminum nitrate solution with a molar concentration of 0.1mol / L, and place them at 40°C In the constant temperature water bath box, after the temperature is stabilized, it is ready for use; wherein, the calcium-silicon molar ratio is 1.0, and the aluminum-silicon molar ratio is 0.05;

[0041] (2) Configure 100ml of polycarboxylate superplasticizer dispersion with a mass fraction of 6.0%, and stir with a laboratory magnetic stirrer for 30min at a water bath temperature of 40°C;

[0042] (3) The above-mentioned polycarboxylate water-reducer dispersion is used as the bottom liquid, and the pH value is adjusted to 10.5 with a mass fraction of 30% s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com