Anti-static clothes based on dust-free fabric and preparation method thereof

An anti-static and anti-static liquid technology, applied in the direction of clothing, clothing, protective clothing, etc., can solve the problems of affecting the anti-static performance of the anti-static layer, poor compatibility between resin and anti-static liquid, etc., to improve adhesion performance, anti-static Long-lasting and effective performance, the effect of enhancing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

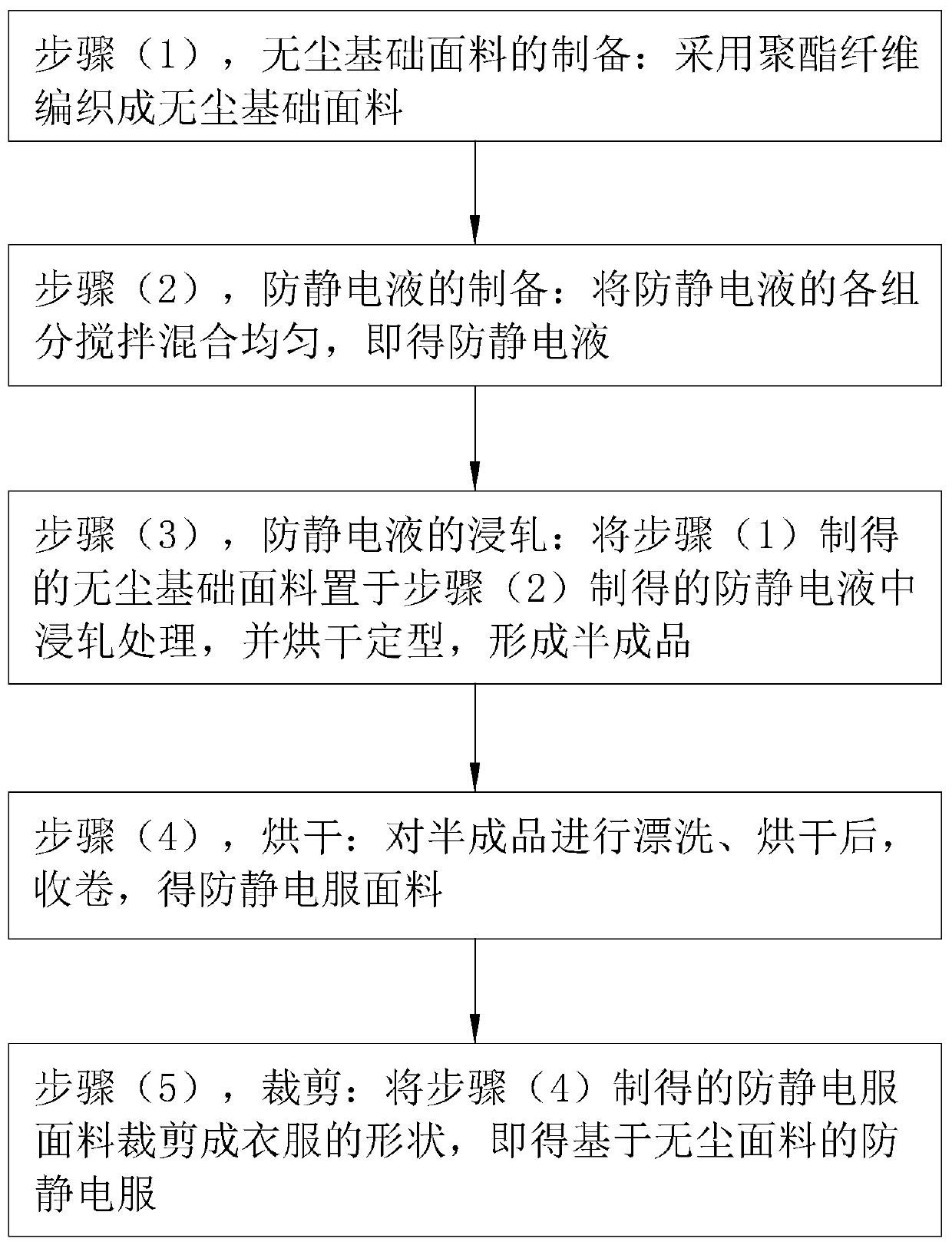

[0072] refer to figure 1 , is a kind of preparation method of the antistatic clothes based on dust-free fabric disclosed by the present invention, comprises the following steps:

[0073] Step (1), the preparation of the dust-free basic fabric, is as follows:

[0074] Use the textile machine to make the resistance value 1.0×10 5 Ω's antistatic carbon fiber and polyester fiber are mixed and woven into a dust-free basic fabric, and the density of the antistatic carbon fiber is 2.5mm in the warp and weft directions. Then put the dust-free basic fabric into a thousand-class clean room for dust-free treatment, use ultra-pure water with a resistance value of 18.2MΩ to clean for 4 cycles, and dry.

[0075] Step (2), the preparation of antistatic liquid, specifically as follows:

[0076] Add 70kg of water into a 100L stirred tank, stir at a speed of 220r / min at room temperature, and add 5kg of antistatic agent, 3kg of sodium stearate, 2kg of acrylic acid emulsion, 1.5kg of polyvinyl...

Embodiment 2

[0085] The difference with embodiment 1 is:

[0086] The consumption of each component that adds in the step (2) is as follows:

[0087] Water 75kg; antistatic agent 4kg; sodium stearate 2kg; acrylic acid emulsion 1.5kg; polyvinylpyrrolidone 1.25kg; sodium lactate 0.75kg.

Embodiment 3

[0089] The difference with embodiment 1 is:

[0090] The consumption of each component that adds in the step (2) is as follows:

[0091] Water 80kg; antistatic agent 3kg; sodium stearate 1kg; acrylic acid emulsion 1kg; polyvinylpyrrolidone 1kg; sodium lactate 0.5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com