Preparation method of highly-doped radiation refrigeration composite fiber and preparation method of highly-doped radiation refrigeration composite fiber fabrics

A radiation cooling and composite fiber technology, applied in the direction of fabrics, fiber chemical characteristics, conjugated synthetic polymer artificial filaments, etc., can solve the problems of limited radiation cooling effect, inability to use human skin to cool down, and high cost, and achieve excellent radiation cooling Performance and mechanical properties, excellent day and night radiation cooling performance, high mechanical properties and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

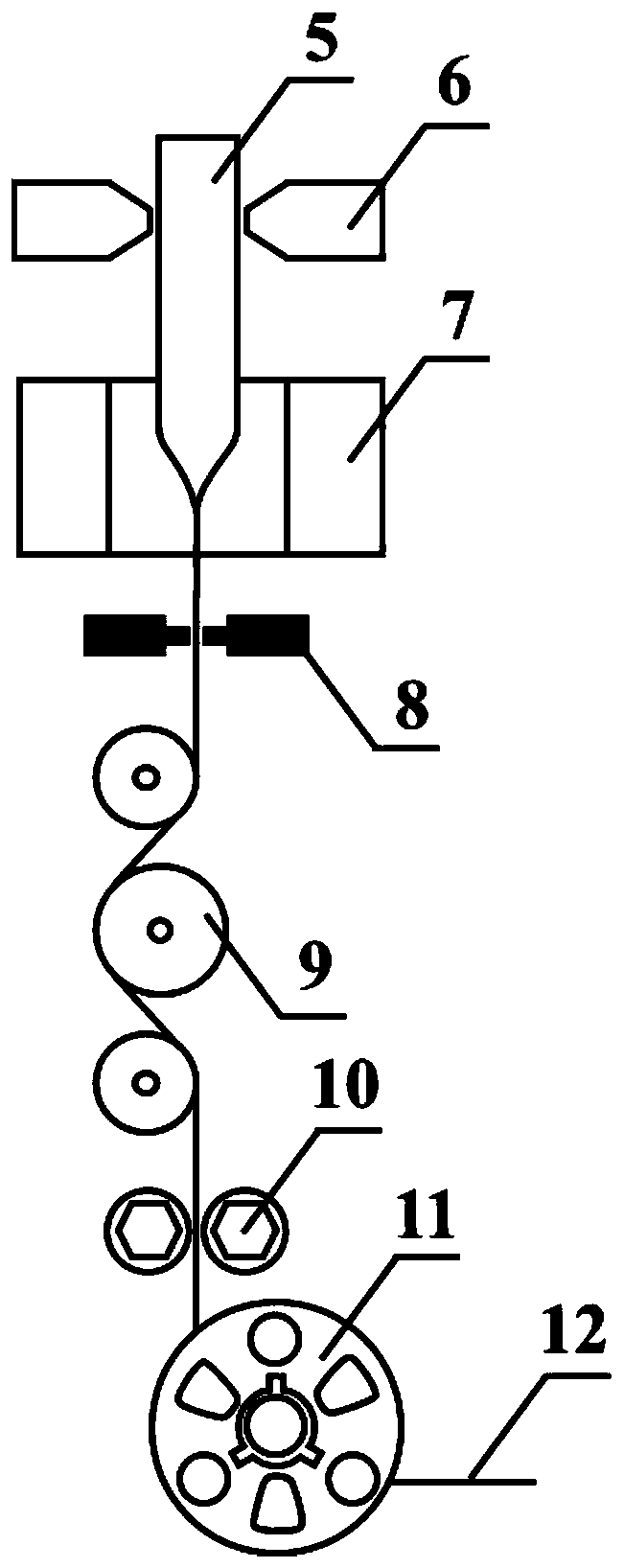

[0043] The preparation steps of the radiant refrigeration conforming material fiber are as follows:

[0044] 101. Prepare a radiative refrigeration composite material mixed with a polymer base material and inorganic micro-nano particles;

[0045] 102. Prepare a fiber preform comprising the radiative refrigeration composite material;

[0046] 103. Thermally drawing the fiber preform to obtain a radiation cooling composite fiber includes thermally drawing the fiber preform on a wire drawing device to obtain a radiation cooling composite fiber with uniform wire diameter.

[0047] Preferably, the preparation of the radiative refrigeration composite material mixed with the polymer base material and the inorganic micro-nano particles includes uniformly compounding the inorganic micro-nano particles and the polymer base material through chemical dissolution mixing and / or physical blending steps.

[0048] Specifically, both the inorganic micro-nano particles and the polymer can be di...

Embodiment approach

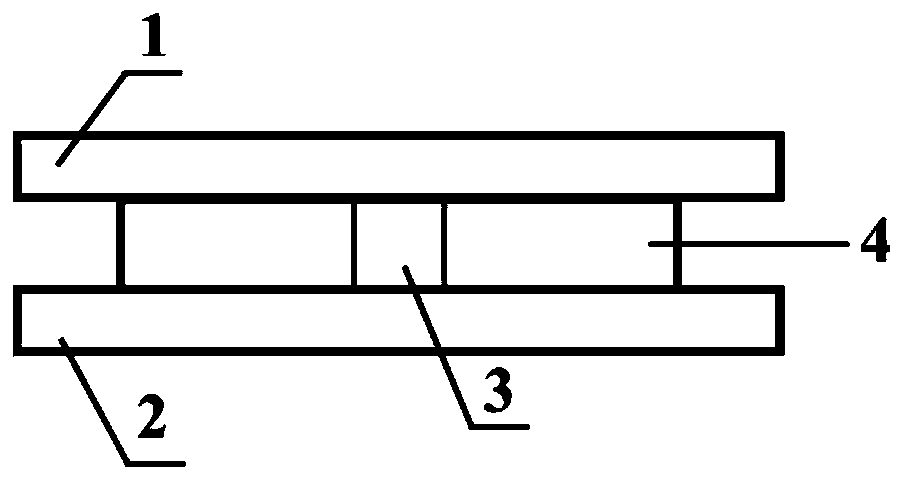

[0050] The preparation of the fiber preform rod containing the radiation cooling composite material includes processing the radiation cooling composite material to obtain a fiber preform rod of the radiation cooling composite material; the fiber preform rods in this structure are all obtained by processing the radiation cooling composite material , Therefore, the obtained fiber preform rod and the subsequently drawn fiber are made of polymer base material and inorganic micro-nano particle material distributed therein.

[0051] On the other hand, the preparation of the fiber preform containing the radiation cooling composite material also includes processing and combining the radiation cooling composite material with other polymer materials to form a fiber preform rod of composite structure.

[0052] Preferably, the other polymer material can be a pure thermoplastic polymer material, or a polymer material doped with inorganic micro-nano particles. Other polymer materials can be...

Embodiment 1

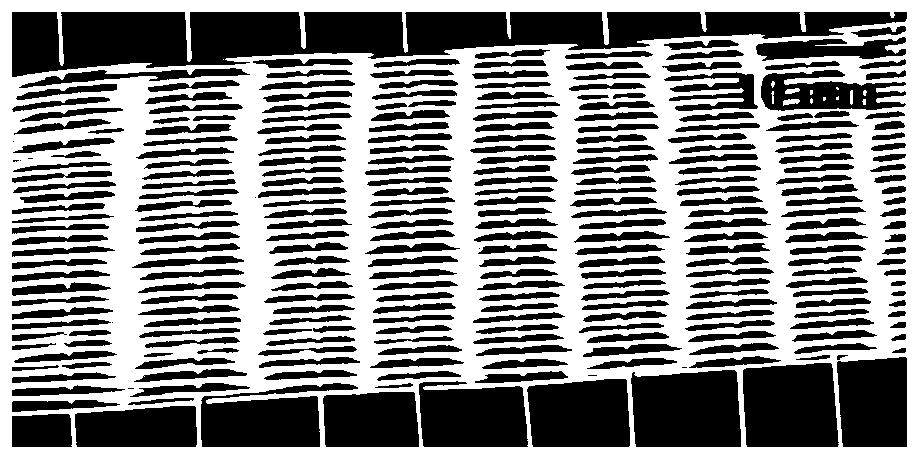

[0070] In this embodiment, the highly doped radiative cooling composite material fibers and fabrics are provided, which have excellent radiative cooling performance and are suitable for radiative cooling of the surface of human skin.

[0071] Wherein, the polymer base material of the radiation refrigeration fiber is a composite material (F-PMMA) of fluororesin and polymethyl methacrylate, and the doped inorganic micro-nano particles are TiO 2 , with an average particle size of about 600nm, accounting for 5% of the total volume of the radiation refrigeration composite material.

[0072] The method for preparing highly doped radiation refrigeration composite fiber and fabric provided in this embodiment includes: preparation of radiation refrigeration composite material, preparation of fiber preform, hot drawing of fiber preform into radiation refrigeration composite fiber, and radiant refrigeration Refrigeration composite fibers are made into radiative refrigeration composite fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com