A millimeter-scale multi-core capsule for delivering nutrients/drugs to the small intestine and slow-release and its preparation method and application

A technology of multi-core capsules and nutrients, which is applied in the fields of targeted carriers, food and medicine, can solve the problems of single bioavailability, rapid release behavior, uneven distribution, etc., and achieve a suitable loading rate and a simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation of embodiment 1 sodium alginate solution

[0062] Weigh a certain amount of sodium alginate solid powder and disperse it in ultrapure water, swell in a 40°C water bath for 30 minutes, and use a magnetic stirrer to stir at a rate of 500rpm for 3-4h (mainly based on dissolution) to ensure complete dissolution. , stand for defoaming to obtain sodium alginate solutions with concentrations of 0.25wt%, 0.5wt%, 1.0wt%, 2.0wt%, 3.0% and 4.0wt%.

Embodiment 2

[0063] The preparation of embodiment 2 sodium alginate emulsion

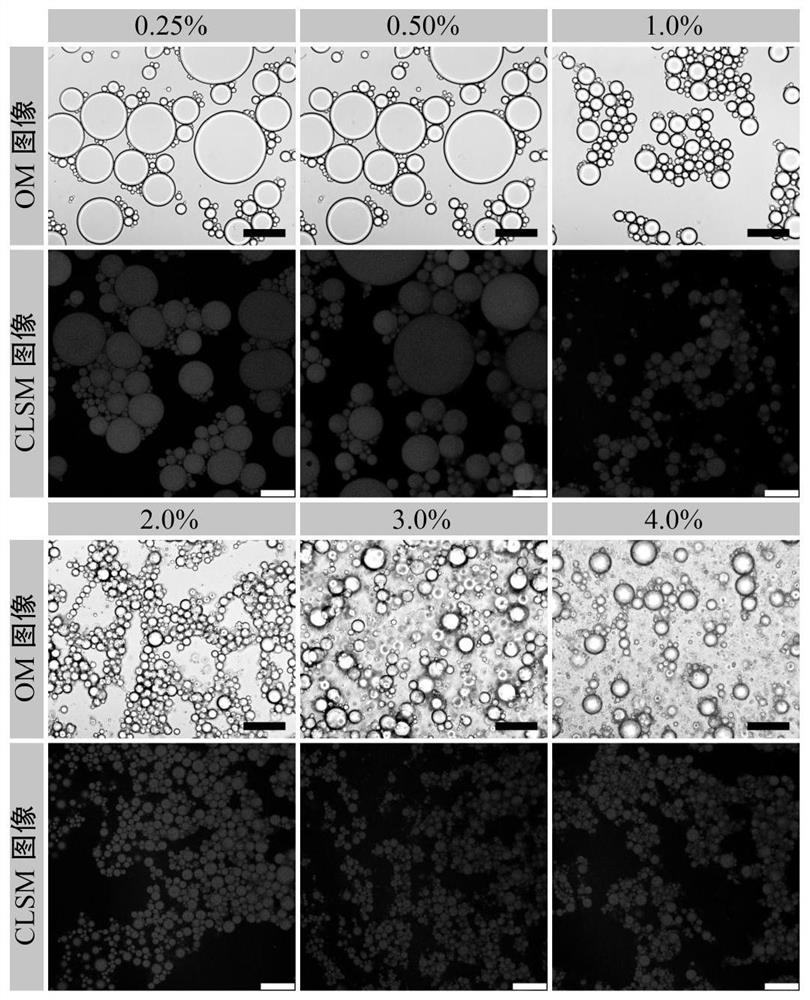

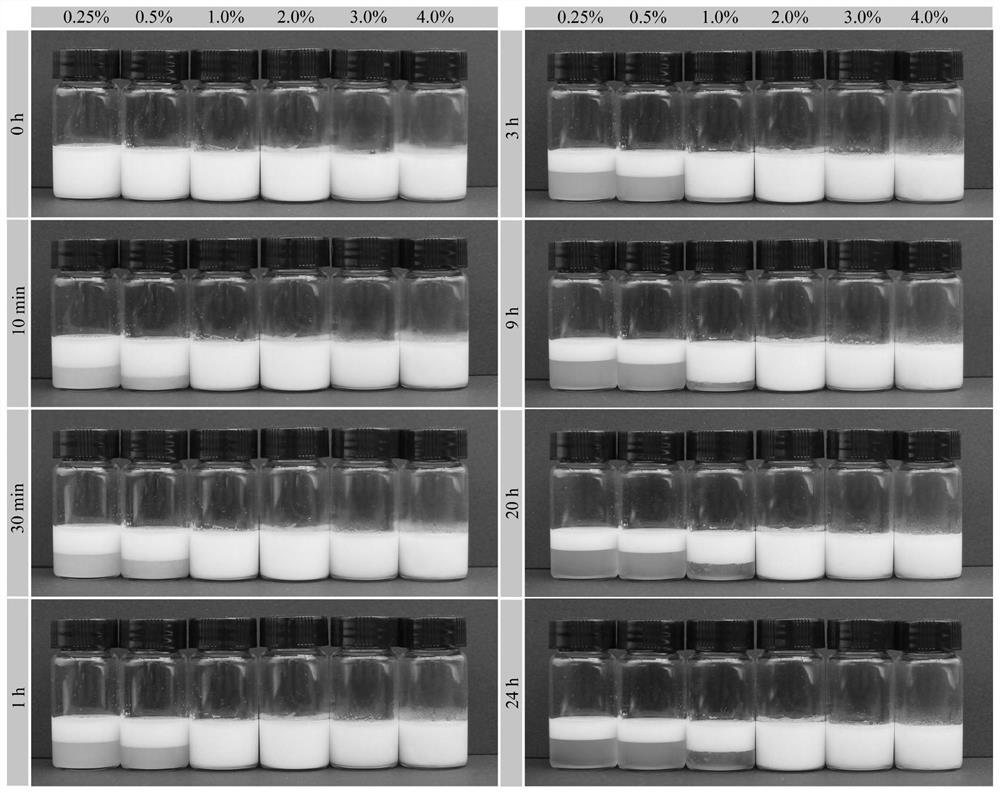

[0064] Measure 6mL of the above-mentioned sodium alginate solution, add 2mL of fish oil according to the ratio of sodium alginate solution: fish oil=3:1 (volume ratio), use a 10mm head homogenizer to homogenize for 60s at a speed of 8000rpm to obtain a sodium alginate emulsion; like figure 2 As shown in the digital camera image at 0 h, the sodium alginate emulsion was milky white. like figure 1 These emulsions consisted of fish oil droplets as shown in the inverted optical microscope image (OM image), which is consistent with the characterised structure of conventional emulsions, proving that they are emulsions. The droplet diameters were most varied at low alginate concentrations (0.25% and 0.5%), and the droplets at the 2.0% alginate concentration were more uniform in diameter. Use a digital camera to observe how these emulsions are stored at room temperature for 24 hours ( figure 2 ). The initial emuls...

Embodiment 3

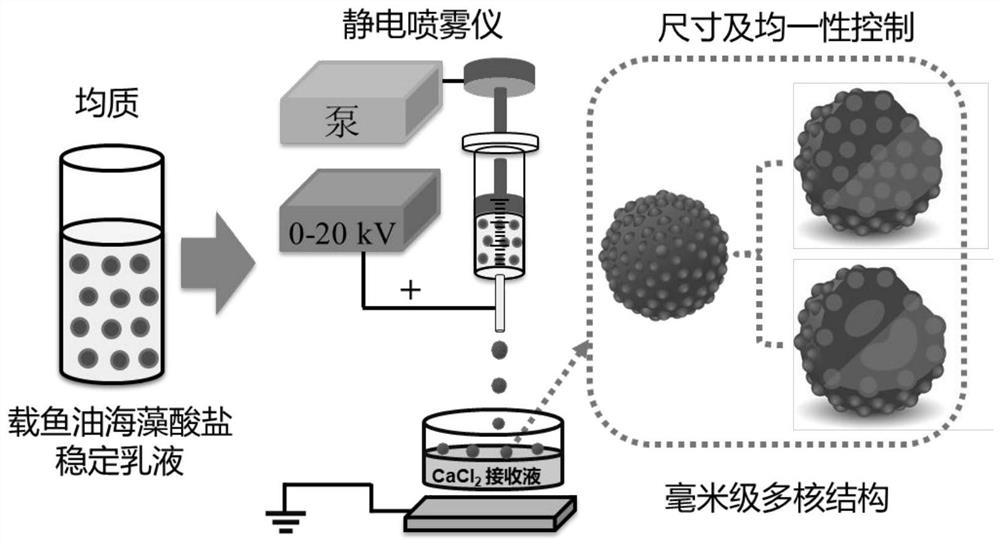

[0065] The preparation of embodiment 3 sodium alginate millimeter-level multi-core capsules

[0066] Millimeter-sized multinuclear capsules were prepared using an electrostatic sprayer (Changshan Naiyi Co., Ltd., model JDE01). with 25mM CaCl 2The solution is used as the receiving liquid, the operating temperature is 25-30°C, and the relative humidity is 30%-40%. The sodium alginate emulsion (2.0%) was put into a 5 mL syringe, and the syringe was connected to a pipeline, and the inner diameter of the needle at the other end of the pipeline was 0.60 mm. A high-voltage power supply was used, and the applied voltage was 10kV. Set the feed rate to 30 μL / min. The distance between the needle and the liquid level of the receiving liquid is 10 cm. Connect the needle tube, pipeline and needle to the electrostatic sprayer, turn on the equipment and spray the sodium alginate emulsion into the calcium chloride receiving solution, and gelation reaction occurs to prepare millimeter-level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com