Preparation method of black phosphorene/graphene oxide composite water-based lubricating additive

A technology of graphene composite and lubricating additives, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of anti-oxidation lubrication failure, poor multi-functionality, etc., to improve anti-friction and anti-wear performance, reduce friction coefficient, save resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment proposes a preparation method of black phosphorene / graphene oxide composite water-based lubricating additive, comprising the following steps:

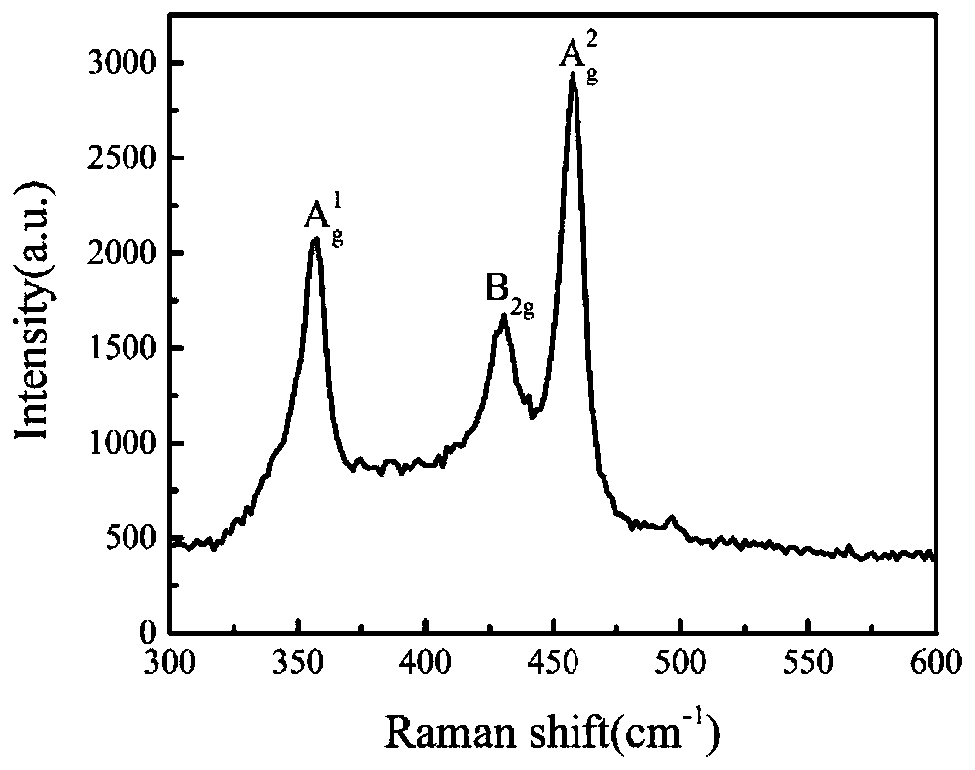

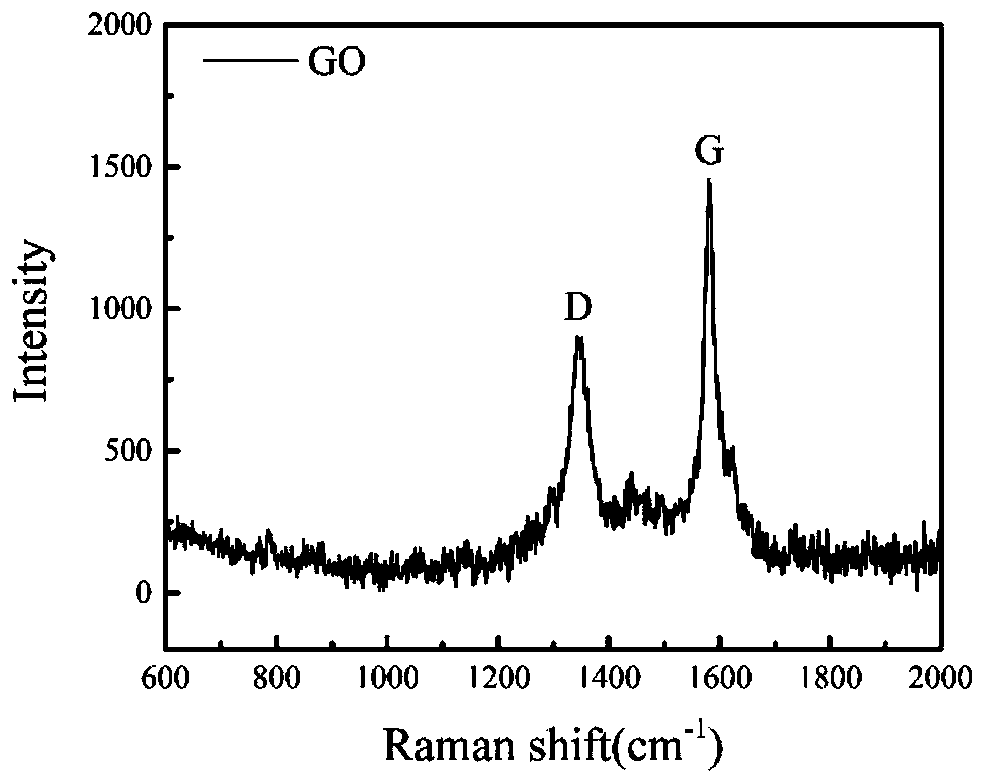

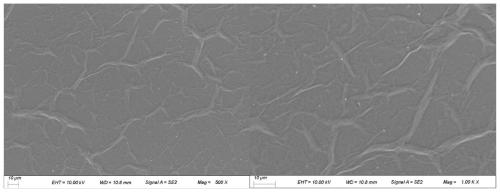

[0039] (1) Preparation of black phosphorene nanosheets: 2 g of red phosphorus powder and stainless steel balls with a diameter of 10-20 mm were added to a ball mill jar according to a ball-to-material ratio of 50:1 and vacuum-sealed. Phosphorus powder. 0.5 g of black phosphorus powder was added to 200 ml of N-methylpyrrolidone solution for 8 hours of ultrasonic treatment in an ice-water bath, and then the resulting solution was centrifuged at 3000 rpm for 20 minutes, and the supernatant was taken out. Subsequently, the supernatant was centrifuged at 11,000 rpm for 30 minutes to obtain a precipitate, which was repeatedly washed with absolute ethanol and dried in vacuum to obtain black phosphorene nanosheets.

[0040] Preparation of black phosphorene dispersion: Prepare 100ml of black phosphorus water-based disper...

Embodiment 2

[0044] This embodiment provides a method for preparing a black phosphorene / graphene oxide composite water-based lubricating additive, comprising the following steps:

[0045] (1) Preparation of black phosphorene nanosheets: 2 g of red phosphorus powder and stainless steel balls with a diameter of 10-20 mm were added to a ball mill jar according to a ball-to-material ratio of 50:1 and vacuum-sealed. Phosphorus powder. 0.5 g of black phosphorus powder was added to 200 ml of N-methylpyrrolidone solution for 8 hours of ultrasonic treatment in an ice-water bath, and then the resulting solution was centrifuged at 3000 rpm for 20 minutes, and the supernatant was taken out. Subsequently, the supernatant was centrifuged at 11,000 rpm for 30 minutes to obtain a precipitate, which was repeatedly washed with absolute ethanol and dried in vacuum to obtain black phosphorene nanosheets.

[0046] Preparation of black phosphorene dispersion: Prepare 100ml of black phosphorus water-based dispe...

Embodiment 3

[0050] This embodiment provides a method for preparing a black phosphorene / graphene oxide composite water-based lubricating additive, comprising the following steps:

[0051] (1) Preparation of black phosphorene nanosheets: 2 g of red phosphorus powder and stainless steel balls with a diameter of 10-20 mm were added to a ball mill jar according to a ball-to-material ratio of 50:1 and vacuum-sealed. Phosphorus powder. 0.5 g of black phosphorus powder was added to 200 ml of N-methylpyrrolidone solution for 8 hours of ultrasonic treatment in an ice-water bath, and then the resulting solution was centrifuged at 3000 rpm for 20 minutes, and the supernatant was taken out. Subsequently, the supernatant was centrifuged at 11,000 rpm for 30 minutes to obtain a precipitate, which was repeatedly washed with absolute ethanol and dried in vacuum to obtain black phosphorene nanosheets.

[0052] Preparation of black phosphorene dispersion: Prepare 100ml of black phosphorus water-based dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com