High-strength galvanized steel sheet, and method for manufacturing same

A technology of galvanized steel sheet and manufacturing method, applied in the direction of manufacturing tools, chemical instruments and methods, hot-dip plating process, etc., can solve the problems of hydrogen not easy to release, intrusion, hydrogen embrittlement, easy residual hydrogen, etc., and achieve hydrogen embrittlement resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

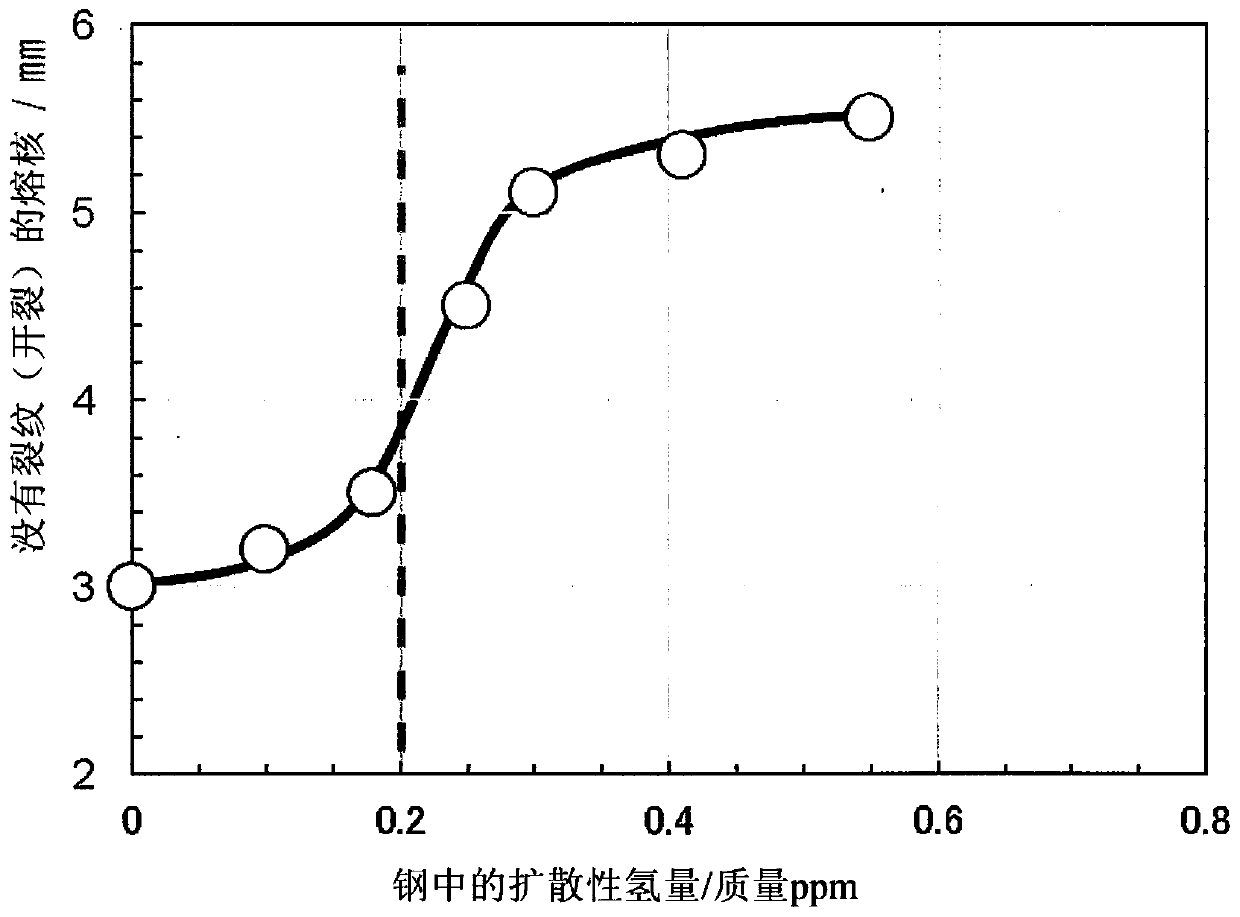

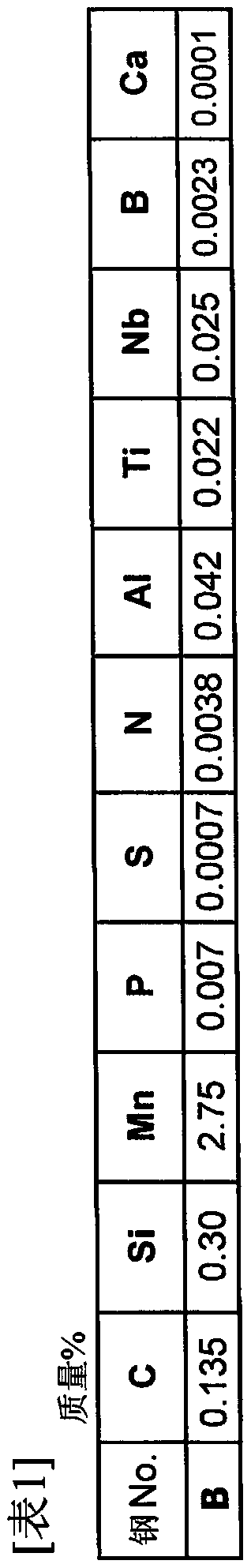

Embodiment 1

[0128] Molten steels having the compositions shown in Table 1 were melted in a converter, and slabs were produced in a continuous casting machine. This slab was heated to 1200°C, and a hot-rolled coil was produced at a finish rolling temperature of 840°C and a coil coiling temperature of 610°C. The hot-rolled coil was made into a cold-rolled billet having a plate thickness of 1.4 mm at a cold reduction rate of 50%. The cold-rolled billet was heated to 810°C (within the range of (Ac3 point -20°C) to 900°C) through annealing treatment with a hydrogen concentration of 9 vol% and an atmosphere in an annealing furnace with a dew point of -30°C, stayed for 60 seconds, and cooled To 500°C, stay for 50 seconds. Afterwards, galvanizing is carried out, alloying treatment is performed, and after plating, it is cooled to below 100°C in a water tank with a water temperature of 40°C, and the average cooling rate is set to 3°C / s to manufacture high-strength alloyed galvanized steel sheets (...

Embodiment 2

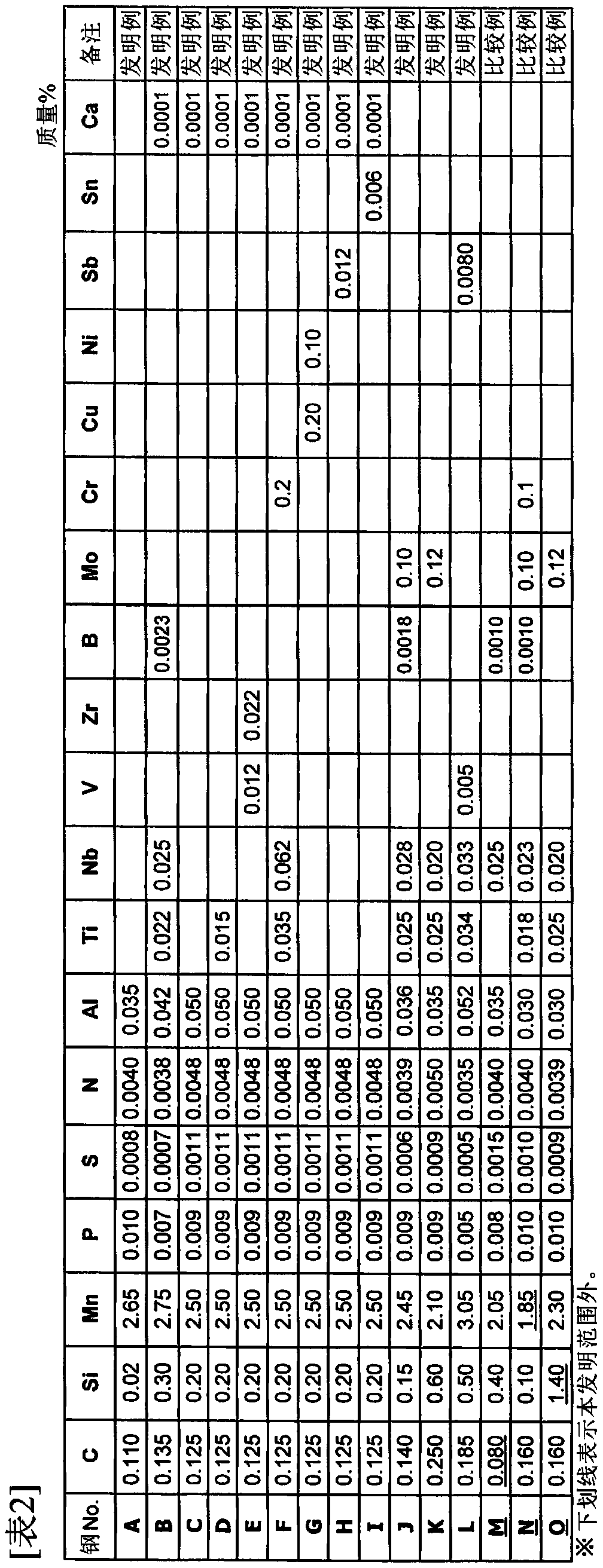

[0139] The molten steel with the composition shown in Table 2 was smelted in a converter, and after being made into a slab by a continuous casting machine, hot rolling, cold rolling, heating (annealing), pickling, pickling, (When "○" is shown in Table 2, the HCl concentration of the pickling solution is adjusted to 5mass%, and the solution temperature is adjusted to 60°C before use.) Perform annealing and plating treatment, temper rolling, width trimming, and post-heat treatment , Manufacture 1.4mm thick high-strength galvanized steel sheet (product sheet). In addition, cooling (cooling after a plating process) passed through the water tank of 40 degreeC of water temperature, and cooled to 100 degreeC or less.

[0140] Take the sample of the galvanized steel sheet obtained above, and use the following method to observe the steel structure and perform a tensile test, measure and calculate the structure fraction (area ratio), yield strength (YS), tensile strength (TS), Yield st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com