Composite gel solid electrolyte, preparation method and all-solid-state lithium ion battery

A lithium-ion battery, solid electrolyte technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, electrolyte immobilization/gelation, etc. problems, to achieve excellent electrochemical stability, increase shrinkage onset temperature, and maintain the effect of chemical window value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

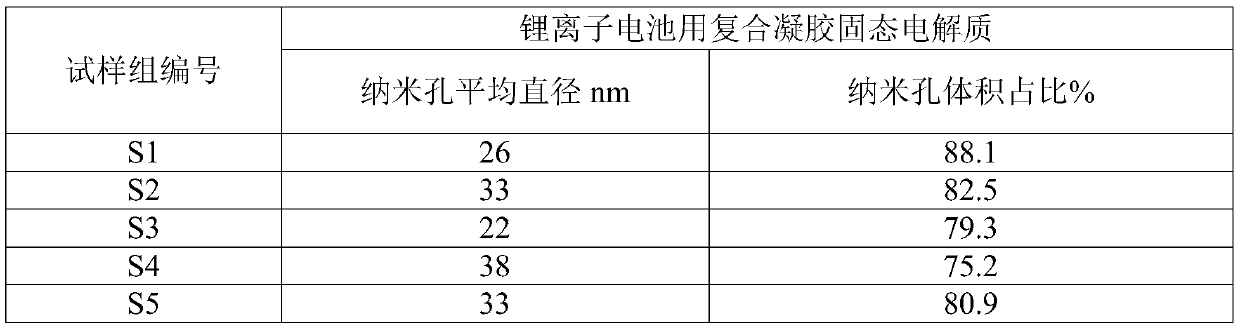

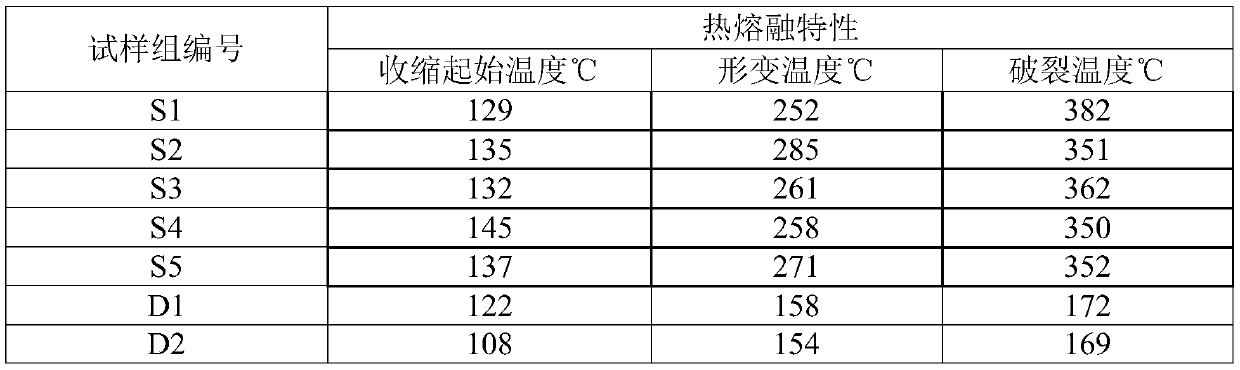

Examples

Embodiment 1

[0036] Preparation of a composite gel solid-state electrolyte for lithium-ion batteries:

[0037] 1. Preparation of lithium bistrifluoromethylsulfonimide composite polyimide gel precursor

[0038] 1) Ingredients: Ingredients by weight: 100 parts by weight of 2,2'-dimethylbenzidine, 153 parts by weight of 3,3',4,4'-biphenyltetraacid dianhydride, N-methyl -2 380 parts by weight of pyrrolidone, 5 parts by weight of 3-aminopropyltrihexyloxysilane, 0.5 parts by weight of lithium bistrifluoromethanesulfonimide, and 180 parts by weight of acetic anhydride;

[0039] 2) Preparation of polyimide gel precursor solution: according to the batching ratio, add 100 parts by weight of 2,2'-dimethylbenzidine and 320 parts by weight of N-methyl-2-pyrrolidone to the vacuum reactor, vacuum The pressure in the reaction kettle is 2.5-3.8MPa, the temperature is 55°C, react for 30-80min, cool to room temperature, and continue the reaction for 150min to obtain the polyimide gel precursor;

[0040] 3)...

Embodiment 2

[0056] Preparation of a composite gel solid-state electrolyte for lithium-ion batteries:

[0057] 1. Preparation of lithium bistrifluoromethylsulfonimide composite polyimide gel precursor

[0058] 1) Ingredients: Ingredients by weight: 100 parts by weight of 2,2'-dimethylbenzidine, 153 parts by weight of 3,3',4,4'-biphenyltetraacid dianhydride, N-methyl -2 380 parts by weight of pyrrolidone, 5 parts by weight of 3-aminopropyltrihexyloxysilane, 0.8 parts by weight of lithium bistrifluoromethanesulfonimide, and 180 parts by weight of acetic anhydride;

[0059] 2) Preparation of polyimide gel precursor solution: according to the batching ratio, add 100 parts by weight of 2,2'-dimethylbenzidine and 320 parts by weight of N-methyl-2-pyrrolidone to the vacuum reactor, vacuum The pressure in the reaction kettle is 2.5-3.8MPa, the temperature is 55°C, react for 30-80min, cool to room temperature, and continue the reaction for 150min to obtain the polyimide gel precursor;

[0060] 3)...

Embodiment 3

[0076] Preparation of a composite gel solid-state electrolyte for lithium-ion batteries:

[0077] 1. Preparation of lithium bistrifluoromethylsulfonimide composite polyimide gel precursor

[0078] 1) Ingredients: Ingredients by weight: 100 parts by weight of 2,2'-dimethylbenzidine, 153 parts by weight of 3,3',4,4'-biphenyltetraacid dianhydride, N-methyl -2 380 parts by weight of pyrrolidone, 5 parts by weight of 3-aminopropyltrihexyloxysilane, 1.2 parts by weight of lithium bistrifluoromethanesulfonimide, and 180 parts by weight of acetic anhydride;

[0079] 2) Preparation of polyimide gel precursor solution: according to the batching ratio, add 100 parts by weight of 2,2'-dimethylbenzidine and 320 parts by weight of N-methyl-2-pyrrolidone to the vacuum reactor, vacuum The pressure in the reaction kettle is 2.5-3.8MPa, the temperature is 55°C, react for 30-80min, cool to room temperature, and continue the reaction for 150min to obtain the polyimide gel precursor;

[0080] 3) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com