Ultraviolet-curing and semi-interpenetrating network-structure polycarbonate-based solid-state polymer electrolyte and preparation method thereof

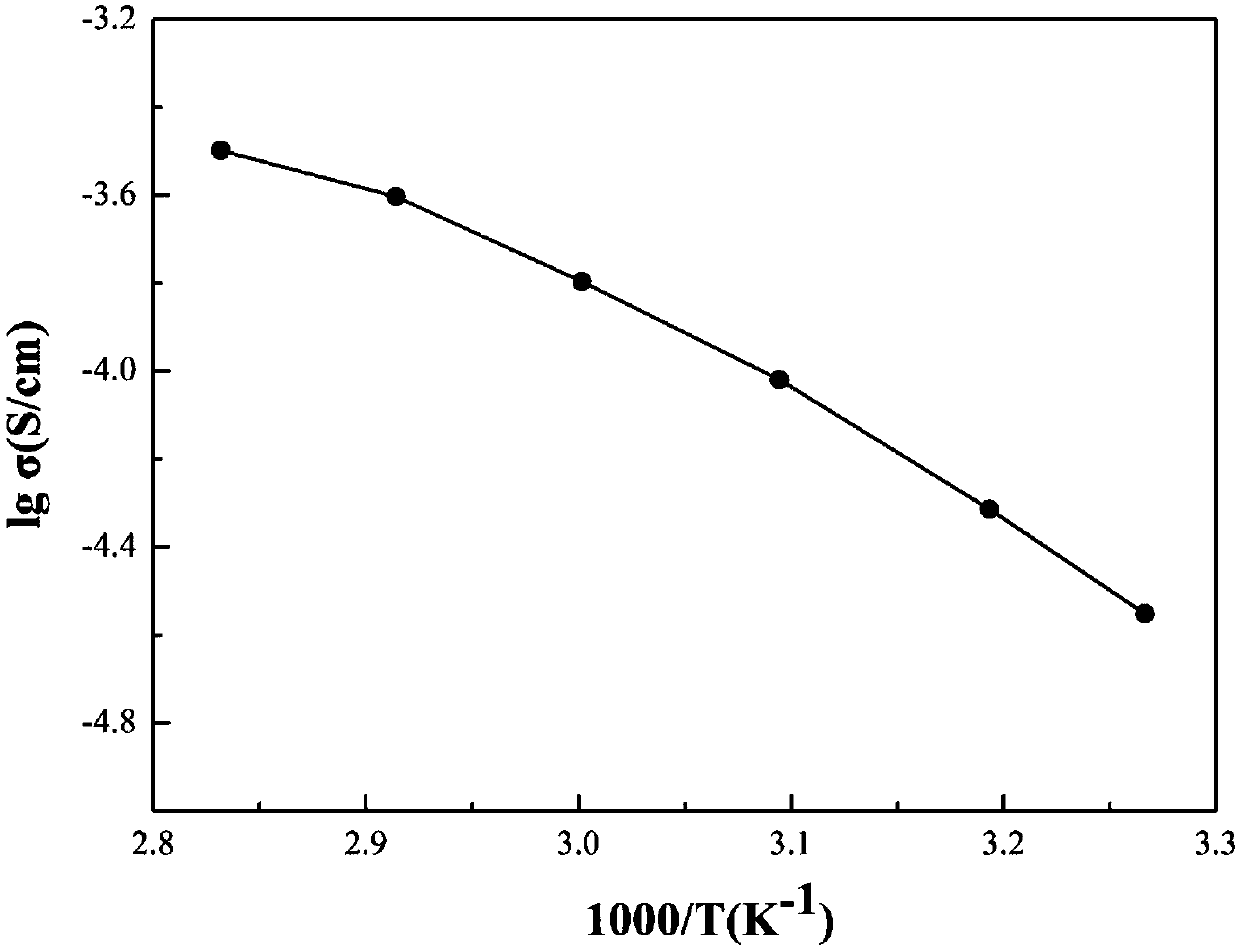

A solid polymer and polycarbonate technology, applied in the field of electrolytes, can solve the problems of poor mechanical properties of electrolytes and inability to achieve self-support, and achieve high room temperature conductivity, good electrochemical and interface stability, and good self-supporting performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Polyethylene carbonate 5g, trimethylolpropane triacrylate 0.5g, bistrifluoromethanesulfonimide lithium 4g, add 60g tetrahydrofuran, add HMPP 0.02g, stir evenly, apply the mixed solution to On the glass, dry the solvent at 60°C, and then perform UV curing to obtain a solid polymer electrolyte membrane.

Embodiment 2

[0027] 1g of polybutylene carbonate, 1g of ethoxylated trimethylolpropane triacrylate, 4g of lithium trifluoromethanesulfonate, add 30g of acetone, add 0.03g of HCPK, stir evenly, and apply the mixed solution on the glass The solvent was dried at 40°C, followed by UV curing to obtain a solid polymer electrolyte membrane.

Embodiment 3

[0029] 2g polypropylene carbonate, 12g propoxylated glycerin triacrylate, 10g lithium dioxalate borate, add 80g acetonitrile, add 0.3g HMPP, stir evenly, apply the mixed solution on the glass, and dry it at 60°C solvent, followed by UV curing to obtain a solid polymer electrolyte membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com