Modified particle-based plastic hose for pouring and production process thereof

A plastic hose and modification technology, applied in the field of plastic hose for pouring based on modified particles and its production process, can solve the problems of limiting the performance of the plastic hose, poor compatibility of the substrate, etc., and reduce the interaction force , the effect of extending the distance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

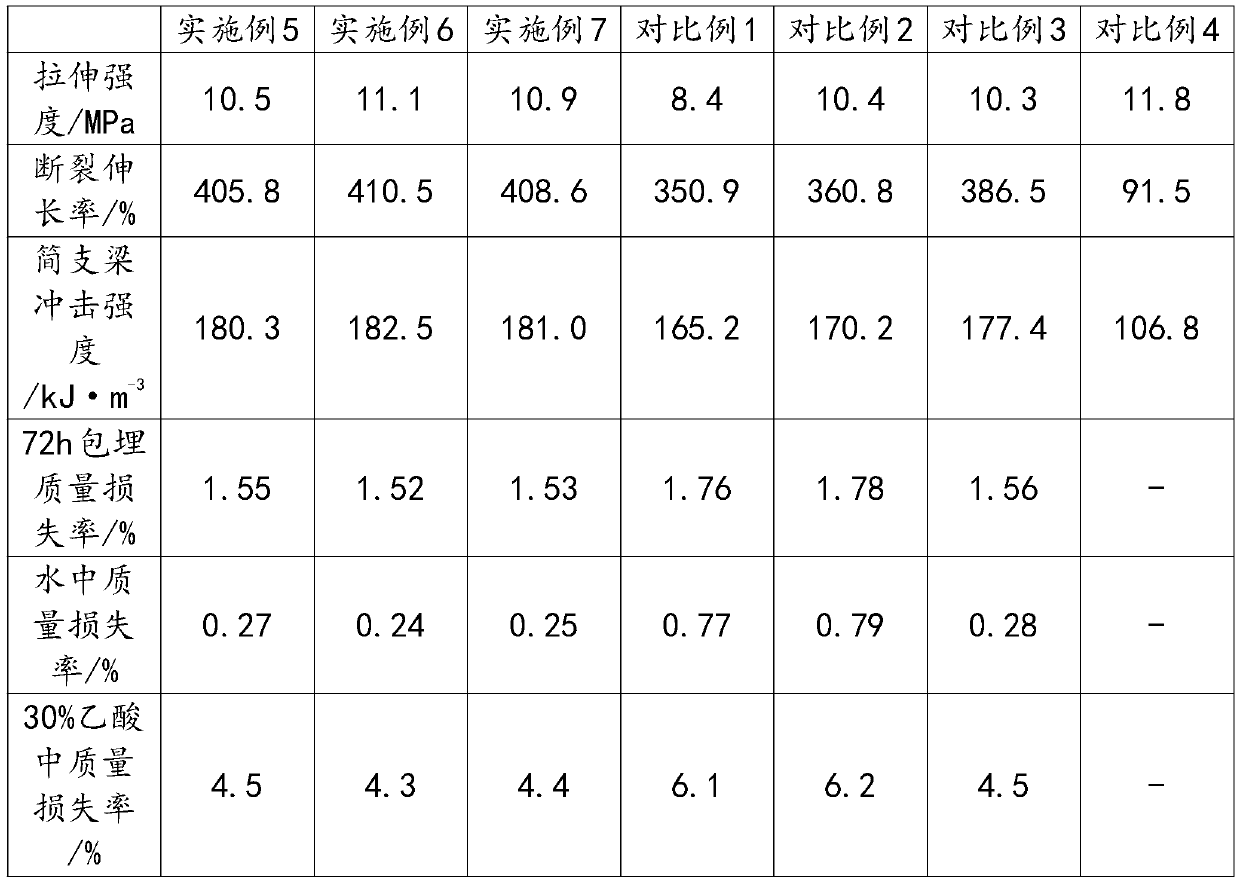

Examples

Embodiment 1

[0047] Modified polyvinyl chloride is prepared by the following method:

[0048] S1. Add acryloyl chloride and acetone into the reactor, stir to dissolve and then add thiosalicylic acid and potassium carbonate. While stirring and heating up, nitrogen gas is introduced. When the temperature of the mixed solution reaches 48°C, it is protected under nitrogen at 48°C. Under the conditions of reaction for 12 hours, after the reaction was completed, the first extraction was carried out with ethanol, the crude product was vacuum-dried at 100°C for 2 hours, then poured into tetrahydrofuran, the pH value was adjusted to 4.0 with hydrochloric acid, and then extracted with ethanol for the second time. The product was then vacuum-dried at 100°C for 2 hours to obtain a modifier;

[0049] Wherein, the ratio of the consumption (mass) of acetone, acryloyl chloride, thiosalicylic acid, and potassium carbonate is 125:6:10:10;

[0050] S2. Add 10g of PVC, 0.04g of initiator (BPO), 80mL of 1,2-d...

Embodiment 2

[0052] Modified polyvinyl chloride is prepared by the following method:

[0053] S1. Add acryloyl chloride and acetone into the reactor, stir to dissolve and then add thiosalicylic acid and potassium carbonate. While stirring and heating up, nitrogen gas is introduced. When the temperature of the mixture reaches 50°C, it is protected under nitrogen at 50°C. Under the conditions of reaction for 10 hours, after the reaction is completed, the first extraction is carried out with ethanol, the crude product is vacuum-dried at 100°C for 3 hours, then poured into tetrahydrofuran, the pH value is adjusted to 4.5 with hydrochloric acid, and then extracted with ethanol for the second time. The product was then vacuum-dried at 100°C for 3 hours to obtain a modifier;

[0054] Wherein, the ratio of the consumption (mass) of acetone, acryloyl chloride, thiosalicylic acid, and potassium carbonate is 125:7:12:11;

[0055] S2. Add 10g of PVC, 0.05g of initiator (BPO), 90mL of 1,2-dichloroetha...

Embodiment 3

[0057] Described plasticizer is prepared by following method:

[0058] Add p-hydroxymethylbenzoic acid, epoxy fatty acid methyl ester, chloroform and N,N-dimethylformamide into the reactor according to a certain proportion, stir and mix evenly, and react at a constant temperature of 60°C for 5 hours. After the end, it was extracted with ethanol, and the product was vacuum-dried at 100°C for 2 hours to obtain a plasticizer;

[0059] Among them, the mass ratio of p-hydroxymethylbenzoic acid, chloroform, epoxy fatty acid methyl ester and N,N-dimethylformamide is 1:12:0.9:0.0001.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charpy impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com