A kind of composite coating magnetic measuring optical fiber and its preparation method

A composite coating and optical fiber technology, which is used in the measurement of magnetic variables, the size/direction of the magnetic field, and the measurement device, etc., can solve the problem of not realizing the accurate measurement of the magnetic field in the monitoring application of superconducting magnets, and improve the measurement accuracy and sensitivity, strain High, low hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

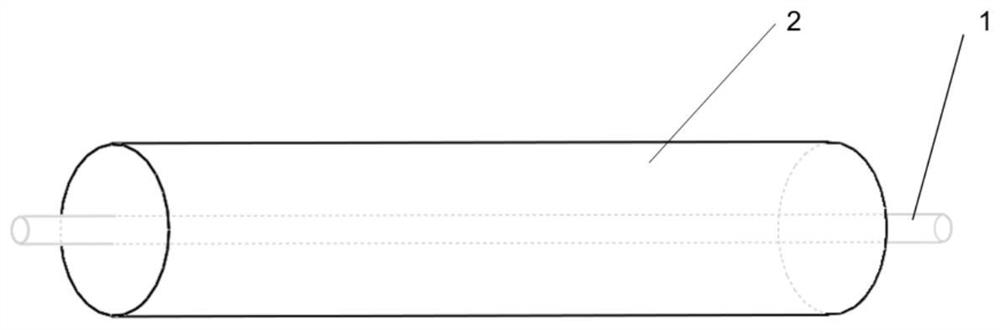

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned composite coating magnetic measuring optical fiber comprises the following steps:

[0035] 1. Apply the acrylic resin to the surface of the bare optical fiber by dip coating-ultraviolet curing process, and form an acrylic resin coating with a layer thickness of 10 μm to 200 μm on the surface of the bare optical fiber;

[0036] 2. Iron-gallium alloy powder (Fe-Ga, Fe, Ga mass ratio is 5:1) and indium-bismuth alloy powder (In, Bi mass ratio is 2:1) prepared by gas atomization method with a particle size of 5-80 μm Mix evenly according to the mass ratio of 85-95:15-5, put it into the coating cup after melting at 80°C;

[0037] 3. Pass the optical fiber coated with acrylic resin coating through the coating cup filled with molten metal alloys (Fe-Ga and InBi) prepared in step 2, and coat the metal alloy melt on the surface of the acrylic resin coating. After cooling, the metal The thickness of the alloy coating is 10 μm to 200 μ...

Embodiment 1

[0040] 1. Apply acrylic resin to the surface of the bare optical fiber by dip coating-ultraviolet curing process, and form a polymer coating with a layer thickness of 100 μm on the surface of the bare optical fiber;

[0041] 2. Mix iron-gallium alloy powder (Fe-Ga) and indium-bismuth alloy powder with a particle size of 25 μm prepared by the gas atomization method at a mass ratio of 95:5, and put them into the coating cup after melting at 80°C;

[0042] 3. Pass the optical fiber coated with acrylic resin coating through a coating cup filled with molten metal alloys (Fe-Ga and InBi), coat the metal melt on the surface of the acrylic resin coating, and the thickness of the metal alloy coating after cooling is 100 μm.

Embodiment 2

[0044] 1. Apply acrylic resin to the surface of the bare optical fiber by dip coating-ultraviolet curing process, and form a polymer coating with a layer thickness of 200 μm on the surface of the bare optical fiber;

[0045] 2. Mix iron-gallium alloy powder (Fe-Ga) and indium-bismuth alloy powder with a particle size of 80 μm prepared by the gas atomization method at a mass ratio of 90:10, and put them into the coating cup after melting at 80°C;

[0046] 3. Pass the optical fiber coated with acrylic resin coating through a coating cup filled with molten metal alloys (Fe-Ga and InBi), coat the metal melt on the surface of the acrylic resin coating, and the thickness of the metal alloy coating after cooling is 200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com