Silicon dioxide modified polypropylene antibacterial material and preparation method thereof

An antibacterial material and silicon dioxide technology, applied in the field of silicon dioxide modified polypropylene antibacterial material and its preparation, can solve the problems of intolerance to soaking, heat intolerance, poor compatibility, etc. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of polypropylene antimicrobial material.

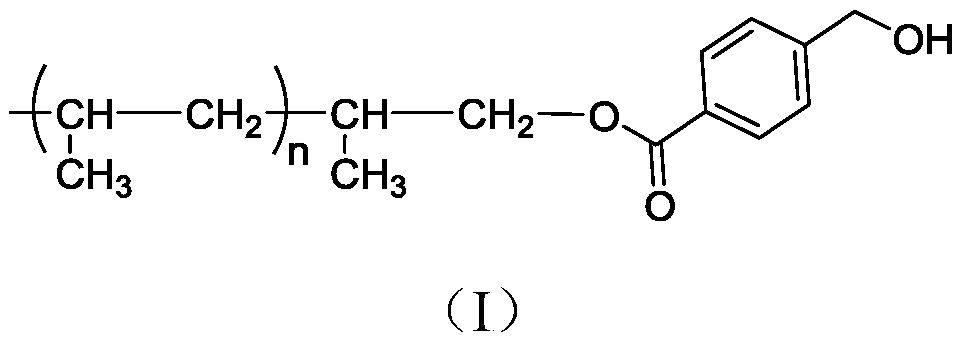

[0027] 4-Hydroxymethylbenzoic acid (5mmol, 0.761g) was dissolved in 20mL of DMF, dichlorosulfite (5mmol, 0.595g) was slowly added dropwise, and reacted at room temperature for 8h to obtain reddish-brown 4-hydroxymethylbenzoyl chloride.

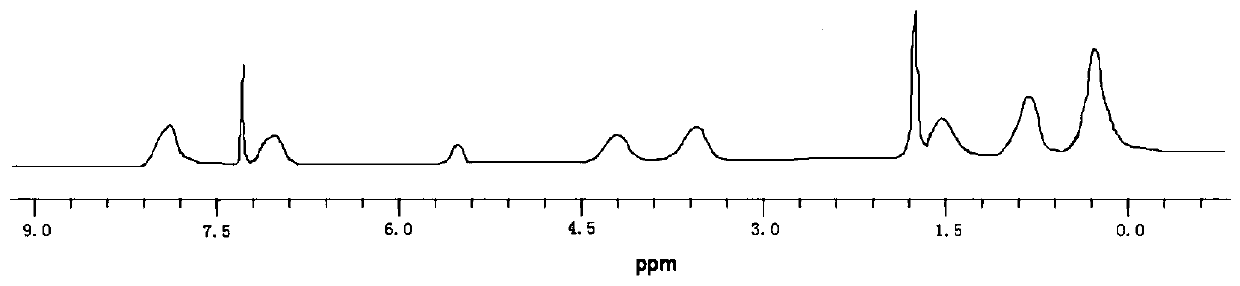

[0028] Add polypropylene (0.50 mmol, 2.70 g) substituted with terminal hydroxyl groups and 20 mL of dioxane into a branched bottle, raise the temperature and keep stirring, and adjust the temperature to 105 ° C after the polypropylene substituted with terminal hydroxyl groups is completely dissolved. Gradually add the above 4-hydroxymethylbenzoyl chloride solution (0.10mmol, 0.085g) dropwise, and after constant temperature reaction for several hours, pour the reaction solution into absolute ethanol to precipitate and filter. After washing several times with absolute ethanol and distilled water several times, use saturated Na 2 CO 3 solution, and finally washed with water until neu...

Embodiment 2

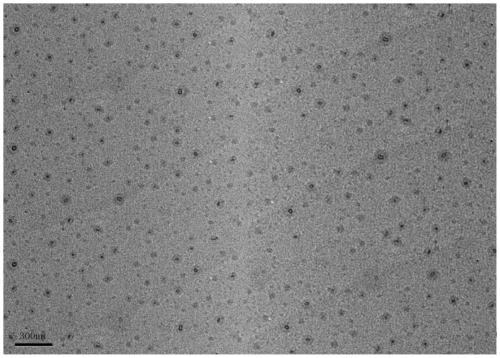

[0030] Preparation of silica-modified polypropylene antibacterial material.

[0031] Place the polypropylene antibacterial material and the silica modified by the silane coupling agent KH570 at 60°C and 100°C for 12 hours, respectively, add 100 parts by weight of the polypropylene antibacterial material to the twin-screw extruder, and silane coupling 5 parts by weight of agent KH570 surface-modified silica, 45 parts by weight of 4-hydroxymethylbenzoic acid, and 0.5 parts by weight of stannous octoate were melt-blended and granulated, the screw speed was 150r / min, and the feed rate was 5kg / h , the temperature is 130-150°C, after granulation and drying, it is foamed in an intermittent foaming device for 12 hours to obtain a silica-modified polypropylene antibacterial material.

Embodiment 3

[0037] Determination of antibacterial effect: Gram-positive bacteria were selected as the object of sterilization for the effect test, and the antibacterial performance was studied by the method of inhibition zone test. Use a meter ruler to measure the size of the inhibition zone around the sample. In order to ensure the accuracy of the data, the width of the inhibition zone of each sample is measured 6 times in different directions at intervals of 60°. The mean value of the zone width, the measured zone size of inhibition. The test results are listed in Table 1.

[0038] Table 1

[0039] project Example 2 Comparative example 1 Comparative example 2 Inhibition zone (mm) 6 18 10

[0040] The results in Table 1 show that the silica-modified polypropylene antibacterial material prepared in Example 2 has a good antibacterial effect, and the polypropylene and organic antibacterial agent 4-hydroxymethylbenzoic acid that do not have antibacterial propert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com