Wear-resistant rare earth rubber material and preparation method thereof

A rare earth rubber and nano-rare earth technology, which is applied in the preparation/treatment of rare earth metal compounds, rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, etc., can solve the poor wear resistance of rubber materials and other problems, to achieve the effect of cheap raw materials, excellent wear resistance, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

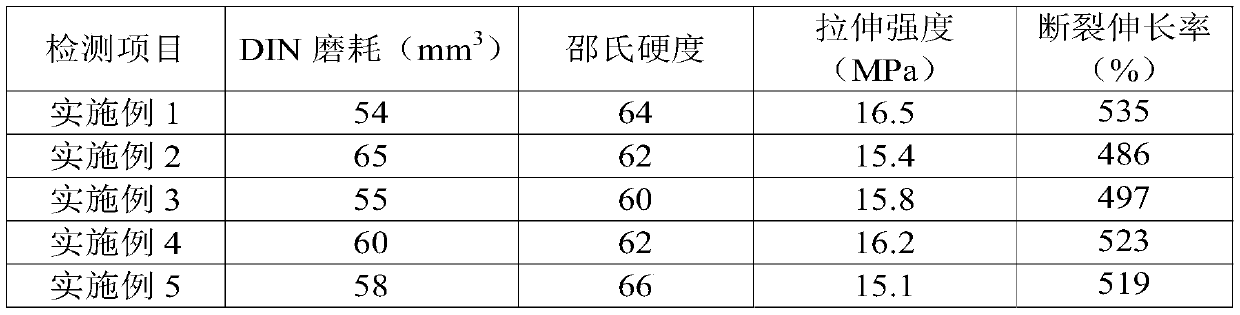

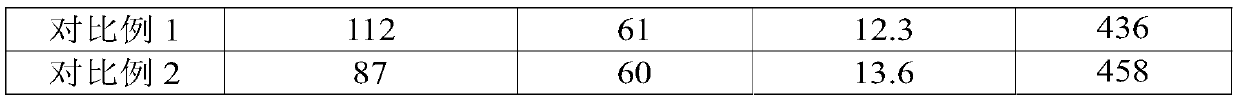

Examples

Embodiment 1

[0033] A kind of wear-resistant rare earth rubber material and preparation method thereof

[0034] The raw materials for preparing wear-resistant rare earth rubber materials include: styrene-butadiene rubber 100kg, natural rubber 20kg, zinc oxide 5.5kg, stearic acid 4.5kg, sulfur 2.5kg, TMTS 1.7kg, microcrystalline wax 1.6kg, filler 40kg, silane 0.035 kg of joint agent, 0.18 kg of nano-rare earth particles; the above-mentioned fillers include 5 kg of activated calcium carbonate, 5 kg of heavy calcium carbonate, 8 kg of sintered clay, 10 kg of talcum powder, and 12 kg of white carbon black.

[0035] Wherein, the preparation method of nano-rare earth particles includes:

[0036] Step a, add 15g of lanthanum oxide powder to 15mL of hydrochloric acid solution with a concentration of 2.5mol / L, add polyethylene glycol after heating for 45 minutes, and then cool to room temperature;

[0037] Step b, adding sodium hydroxide to make the pH of the solution reach 9, stirring and mixing ...

Embodiment 2

[0046] A kind of wear-resistant rare earth rubber material and preparation method thereof

[0047] The raw materials for preparing wear-resistant rare earth rubber materials include: styrene-butadiene rubber 100kg, natural rubber 10kg, zinc oxide 3kg, stearic acid 2.5kg, sulfur 1kg, TMTS 0.8kg, microcrystalline wax 0.6kg, filler 30kg, silane coupling agent 0.02kg, 0.12kg of nano-rare earth particles; the above-mentioned fillers include 10kg of light calcium carbonate and 20kg of hard clay.

[0048] Wherein, the preparation method of nano-rare earth particles includes:

[0049] Step a, add 15g of samarium oxide powder into 15mL of hydrochloric acid solution with a concentration of 2.5mol / L, add polyethylene glycol after heating for 30 minutes, and then cool to room temperature;

[0050] Step b, adding sodium hydroxide to make the pH of the solution reach 9, stirring and mixing for 25 minutes to obtain a suspension;

[0051] Step c, adding deionized water to the suspension und...

Embodiment 3

[0059] A kind of wear-resistant rare earth rubber material and preparation method thereof

[0060] The raw materials for preparing wear-resistant rare earth rubber materials include: styrene-butadiene rubber 100kg, natural rubber 25kg, zinc oxide 8kg, stearic acid 6.5kg, sulfur 4kg, TMTS 2.6kg, microcrystalline wax 2.4kg, filler 50kg, silane coupling agent 0.05kg, nano rare earth particles 0.24kg; the above-mentioned fillers include 8kg of activated calcium carbonate, 6kg of heavy calcium carbonate, 5kg of hard clay, 8kg of sintered clay, 7kg of talcum powder, 8kg of white carbon black and 8kg of lignin activated calcium carbonate.

[0061] Wherein, the preparation method of nano-rare earth particles includes:

[0062] Step a, adding 15 g of cerium oxide powder to 15 mL of hydrochloric acid solution with a concentration of 2.5 mol / L, heating for 60 minutes, adding polyethylene glycol, and cooling to room temperature;

[0063] Step b, adding sodium hydroxide to make the pH of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com