NBR composition for rubber laminated metal

A composition and rubber technology, applied in the direction of rubber layered products, metal layered products, applications, etc., can solve problems such as poor heat resistance, inability to obtain heat-resistant compositions, and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

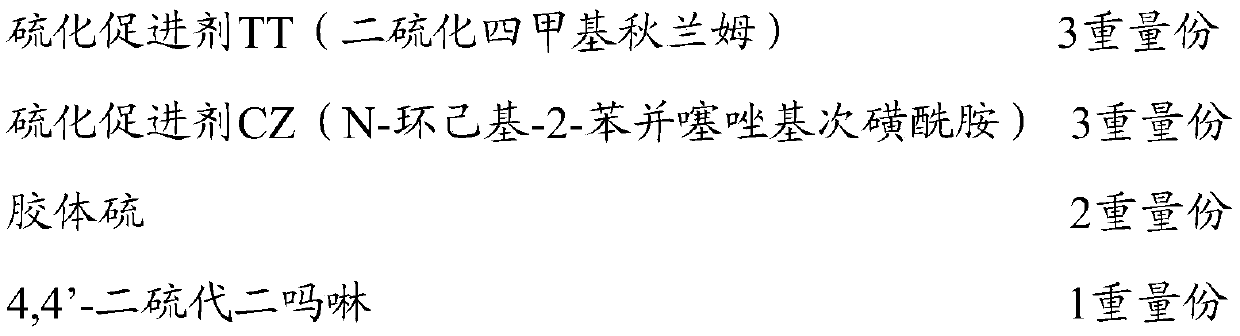

Method used

Image

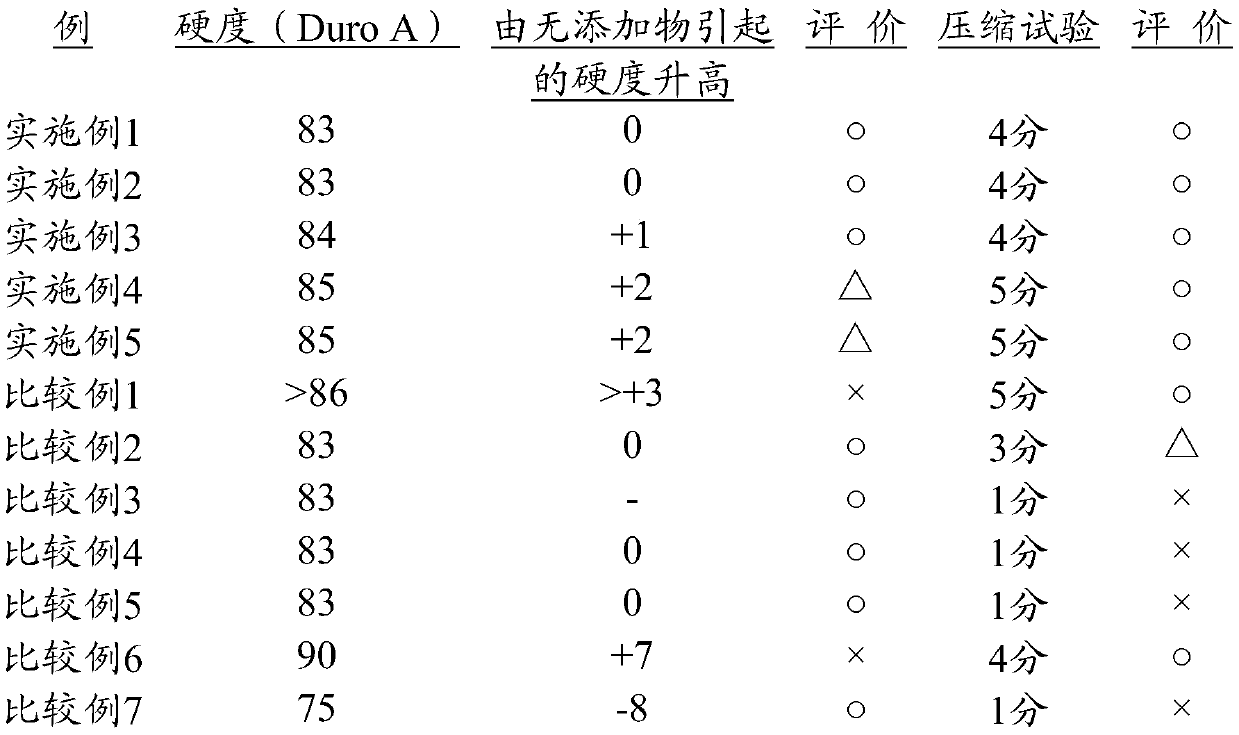

Examples

Embodiment 1

[0052]

[0053]

[0054] The above components were kneaded with a kneader and an open roll, and the kneaded product (composition) was vulcanized at 175° C. for 5 minutes to produce a rubber sheet with a thickness of 2 mm. The hardness of this rubber sheet was measured according to JIS K6253.

[0055] Compression test evaluation samples were produced as follows.

[0056] On an SPCC steel plate (thickness 0.6 mm) surface-treated with zinc phosphate, phenolic resin diluted to a solid content concentration of 5% by weight with organic solvents such as methyl ethyl ketone and methanol is obtained so that the coating thickness after drying on the stainless steel plate is Coating was performed to a thickness of 3 μm, and drying was performed at room temperature. The phenolic resin is not particularly limited as long as it can be vulcanized and adhered to NBR, and for example, commercially available Thixon 715 from Dow Chemical Company and the like can be used.

[0057] The ab...

Embodiment 2

[0069] In Example 1, the amount of 4,4'-dithiodimorpholine was changed to 4 parts by weight.

Embodiment 3

[0071] In Example 1, the amount of 4,4'-dithiodimorpholine was changed to 8 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com