Graphite-based water-based heat-conducting silicate coating and preparation method thereof

A silicate and graphite technology, used in alkali metal silicate coatings and coatings, etc., can solve the problems of poor thermal conductivity and heat dissipation of coatings, poor thermal conductivity and heat dissipation of silicate coatings, and heat can not be dissipated in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

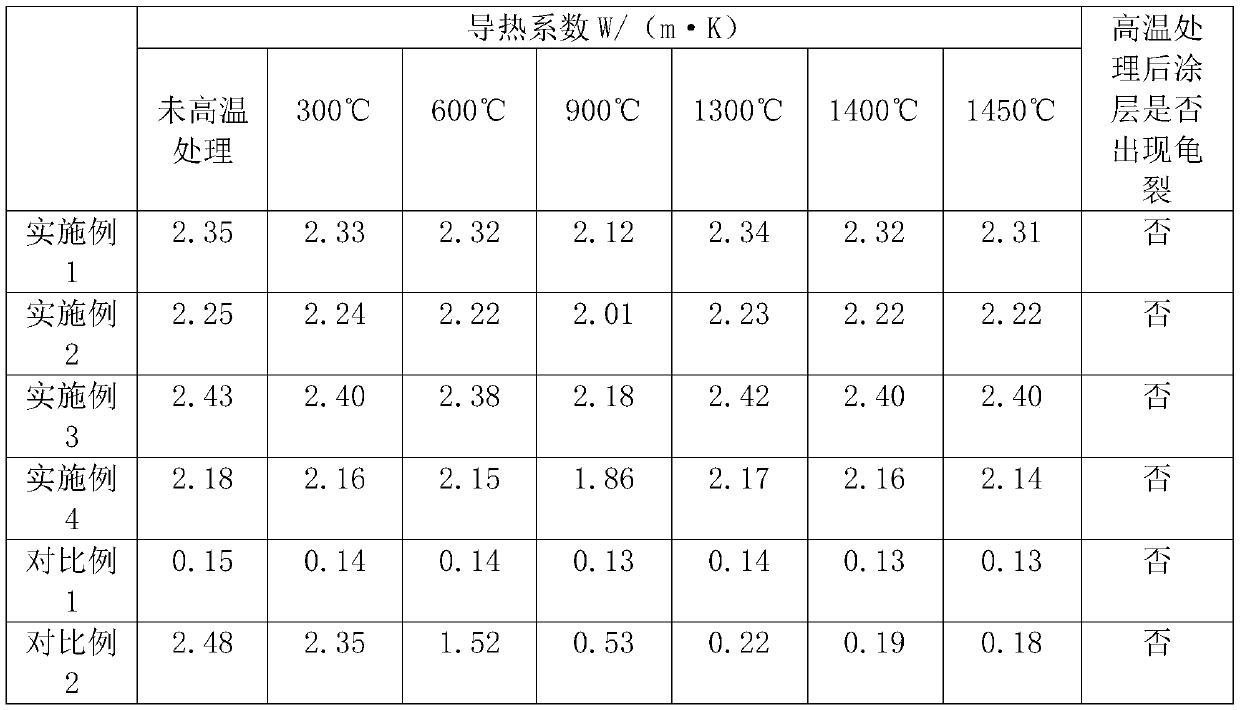

Examples

Embodiment 1

[0029] The preparation method of modified graphite comprises the following steps:

[0030]Put flake graphite in a microwave oven and microwave at 800W for 10s to obtain expanded graphite for later use; mix absolute ethanol and deionized water at a volume ratio of 1:6 to obtain an aqueous ethanol solution, and take sodium silicate and cetyl tris Add methyl ammonium bromide to ethanol aqueous solution and stir to dissolve to obtain a 0.7mol / L sodium silicate solution. The amount of cetyltrimethylammonium bromide added is 6% of the mass of sodium silicate; add ammonium chloride to deionized Stir and dissolve in water to prepare an ammonium chloride solution with a concentration of 2.5 mol / L, heat it in a water bath to 45°C, add expanded graphite and nano-silicon carbide to the ammonium chloride solution, and the mass ratio of the added expanded graphite to sodium silicate is 1 : 2.5, the addition of nano-silicon carbide is 30wt% of expanded graphite, stirring and dispersing to ob...

Embodiment 2

[0036] The preparation method of modified graphite comprises the following steps:

[0037] Put flake graphite in a microwave oven and microwave at 700W for 20s to obtain expanded graphite for later use; mix absolute ethanol and deionized water at a volume ratio of 1:8 to obtain an aqueous ethanol solution, and take sodium silicate and cetyl tris Add methylammonium bromide to ethanol aqueous solution and stir to dissolve to obtain a 0.5mol / L sodium silicate solution. The amount of cetyltrimethylammonium bromide added is 3% of the mass of sodium silicate; add ammonium chloride to deionized Stir and dissolve in water to prepare an ammonium chloride solution with a concentration of 2.0mol / L, heat it in a water bath to 40°C, add expanded graphite and nano-silicon carbide to the ammonium chloride solution, and the mass ratio of the added expanded graphite to sodium silicate is 1 : 1.5, the addition of nano-silicon carbide is 25wt% of expanded graphite, stirring and dispersing to obt...

Embodiment 3

[0043] The preparation method of modified graphite comprises the following steps:

[0044] Put flake graphite in a microwave oven and microwave at 750W for 15s to obtain expanded graphite for later use; mix absolute ethanol and deionized water at a volume ratio of 1:7 to obtain an aqueous ethanol solution, and take sodium silicate and cetyl tris Add methyl ammonium bromide to ethanol aqueous solution and stir to dissolve to obtain a 0.8mol / L sodium silicate solution. The amount of cetyltrimethylammonium bromide added is 5% of the mass of sodium silicate; add ammonium chloride to deionized Stir and dissolve in water to prepare an ammonium chloride solution with a concentration of 3mol / L, heat it in a water bath to 43°C, add expanded graphite and nano-silicon carbide to the ammonium chloride solution, and the mass ratio of the added expanded graphite to sodium silicate is 1: 3. The addition amount of nano-silicon carbide is 35wt% of the expanded graphite, stir and disperse to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com