PTFE nano mask film and preparation method thereof

A technology of PTFE and masks, which is applied in the field of PTFE nano-mask film and its preparation, can solve the problems of poor isolation effect, impenetrability, and decreased protective efficiency of masks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

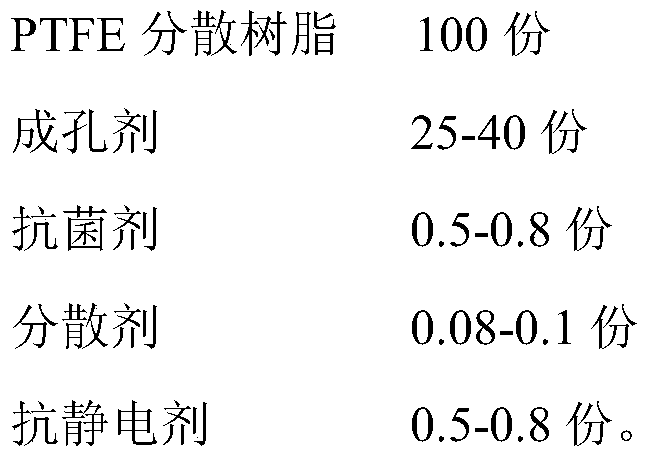

[0040] The PTFE nano-mask film described in the present embodiment 1, in parts by mass, the raw material composition is as follows:

[0041]

[0042]

[0043] in:

[0044] The PTFE dispersion resin is DF-203, and the manufacturer is Shandong Dongyue Polymer Material Co., Ltd.

[0045] The technical indicators of DF-203 are: bulk density 435g / L, tensile strength 30MPa, elongation at break 330%, moisture content < 0.03%, average particle size 470μm.

[0046] The pore forming agent is a mixture of white oil and hydrocarbon solvent oil; the hydrocarbon solvent oil is iso-dodecane; the mass ratio of white oil to iso-dodecane is 3.5:0.7.

[0047] The antibacterial agent is anatase titanium dioxide.

[0048] The dispersant is a fluorocarbon surfactant, and the fluorocarbon surfactant is 3-trimeric epoxyhexafluoropropane amidopropyl betaine.

[0049] The antistatic agent is tris(lauryl)methyl ammonium chloride.

[0050] The preparation method of the PTFE nano mask film descr...

Embodiment 2

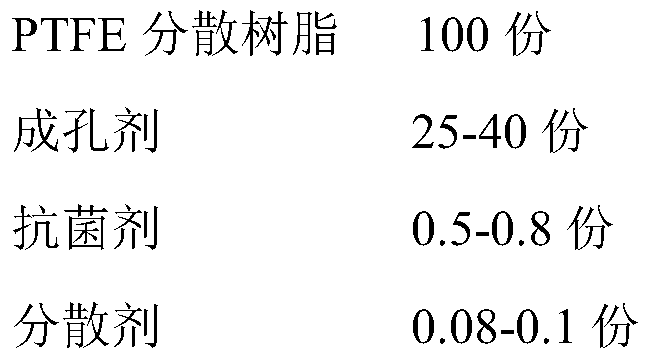

[0064] The PTFE nano-mask film described in present embodiment 2, in parts by mass, raw material composition is as follows:

[0065]

[0066]

[0067] in:

[0068] The PTFE dispersion resin is DF-204, and the manufacturer is Shandong Dongyue Polymer Material Co., Ltd.

[0069] The technical indicators of DF-204 are: bulk density 440g / L, tensile strength 33MPa, elongation at break 355%, moisture content < 0.03%, average particle size 485μm.

[0070] The pore forming agent is a mixture of white oil and hydrocarbon solvent oil; the hydrocarbon solvent oil is isomerized hexadecane; the mass ratio of white oil to isomerized hexadecane is 4:0.5.

[0071] The antibacterial agent is anatase titanium dioxide.

[0072] The dispersant is a fluorocarbon surfactant, and the fluorocarbon surfactant is 8-3-9 fluorocarbon-hydrocarbon flexible bridge mixed-chain diquaternary ammonium.

[0073] The antistatic agent is tris(lauryl)methyl ammonium chloride.

[0074] The preparation meth...

Embodiment 3

[0088] The PTFE nano-mask film described in present embodiment 3, in parts by mass, raw material composition is as follows:

[0089]

[0090] in:

[0091] Described PTFE dispersion resin is 104C, and manufacturer is Japan Daikin.

[0092] 104C technical indicators are: Density: 2.2g / cm 3 , the tensile strength is 34.6MPa, the elongation at break is 480%, the moisture content is 0.01%, and the average particle size is 450μm.

[0093] The pore forming agent is a mixture of white oil and hydrocarbon solvent oil; the hydrocarbon solvent oil is iso-dodecane; the mass ratio of white oil to iso-dodecane is 3:0.6.

[0094] The antibacterial agent is anatase titanium dioxide.

[0095] The dispersant is a fluorocarbon surfactant, and the fluorocarbon surfactant is 3-trimeric epoxyhexafluoropropane amidopropyl betaine.

[0096] The antistatic agent is tris(lauryl)methyl ammonium chloride.

[0097] The preparation method of the PTFE nano mask film described in present embodiment 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com