Multiphase fluorescent ceramic and preparation method thereof

A technology of fluorescent ceramics and dielectric ceramics, applied in chemical instruments and methods, luminescent materials, additive processing, etc., can solve problems such as increasing heterogeneous interfaces and interface phonon scattering, hindering directional transport, and limited contribution to heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment 1, the preparation process of the composite fluorescent ceramics inside includes:

[0042] (1) Accurately weigh 80g Al 2 o 3 For the ceramic powder, 19.3 g of photosensitive resin was added, and after blending, a planetary mill was used to fully mix to obtain a ceramic slurry. The composition of the photosensitive resin comprises 12.3g epoxy acrylate resin, 1.2g epoxy resin, 1.2g2,2-diethoxyacetophenone, 0.8g hydrogenated castor oil and 3.8g tetrahydrofuran acrylate;

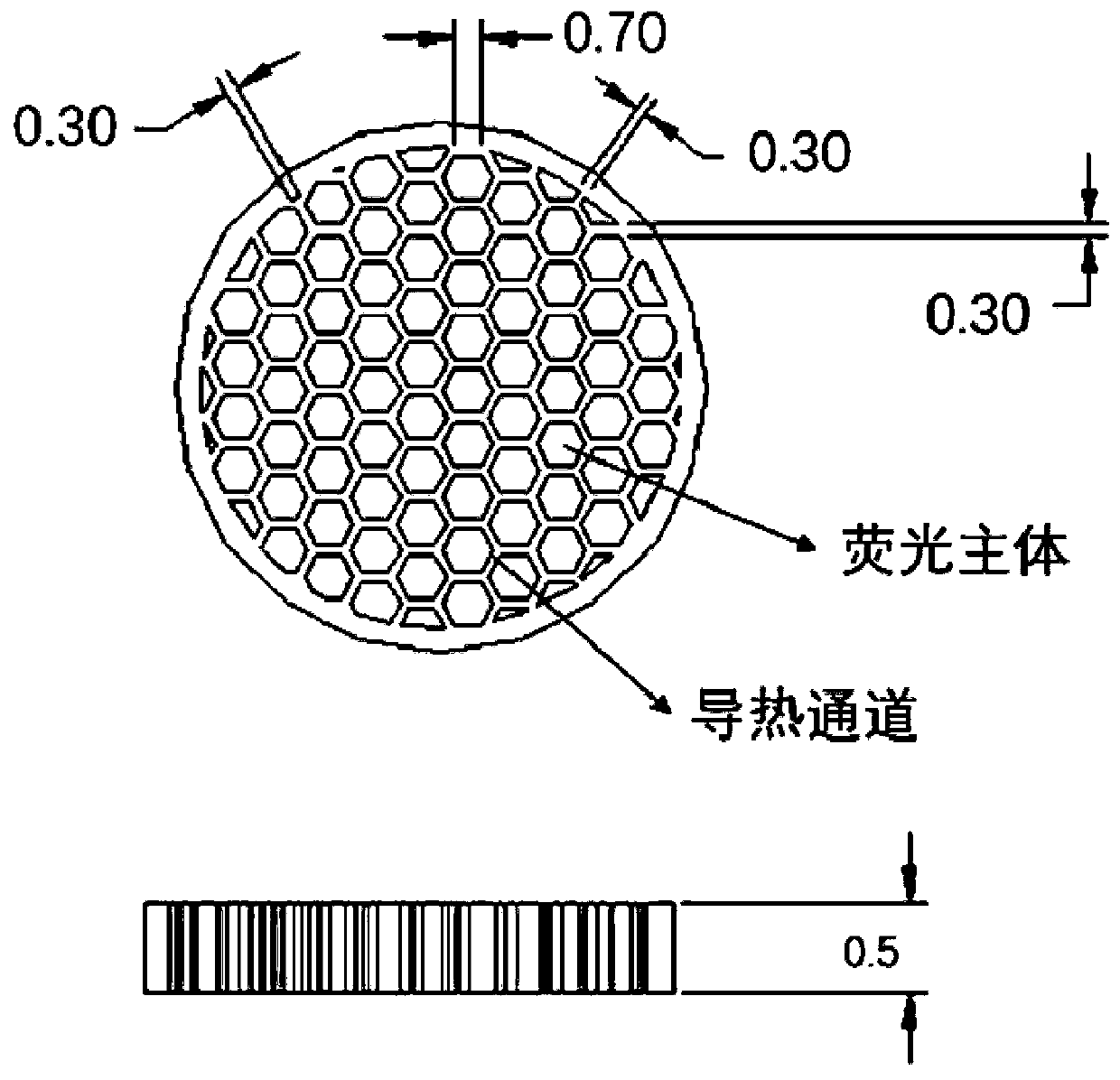

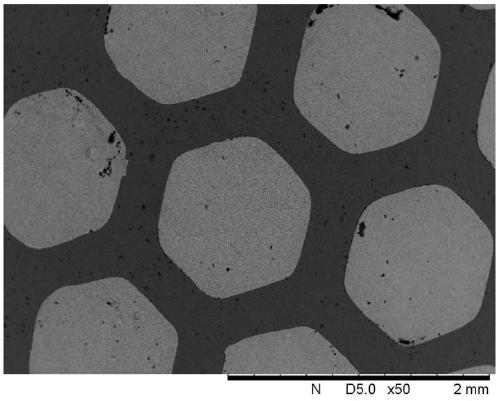

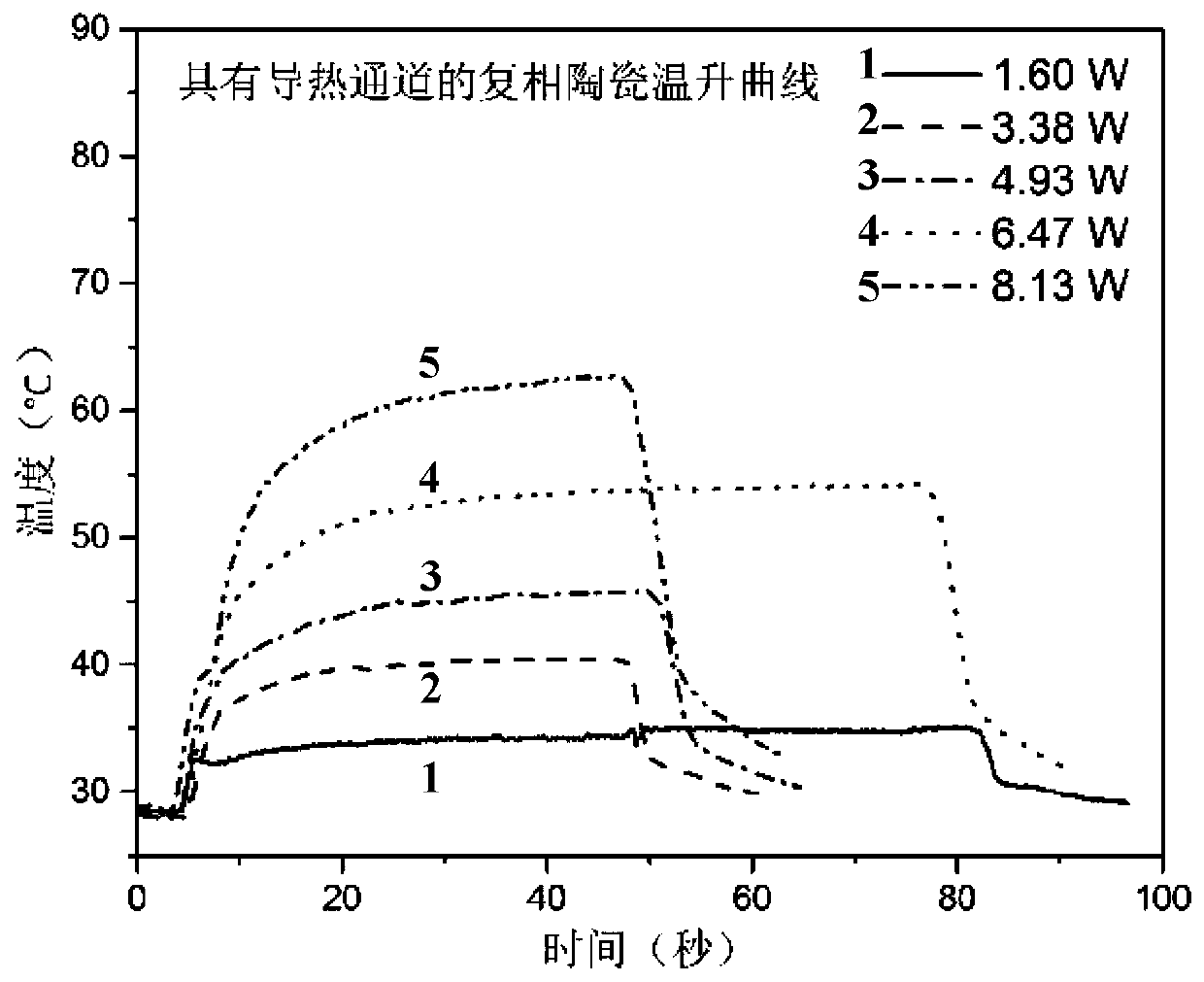

[0043] (2) if figure 1 As shown, the internal periodic structure parameters of the designed periodic structure composite fluorescent ceramics are: δ is 40%; the channel structure is set as a regular hexagon, the wall thickness between the porous channels in the matrix is 300 μm, and the effective side length of the channel structure is set 700μm, and then input into the 3D printer program;

[0044] (3) Pour the obtained ceramic slurry into a 3D printer trough, and print the alumin...

Embodiment 2

[0058] The multiphase fluorescent ceramics in Example 2 are basically the same as in Example 1, the difference is that LuAG:Ce is selected as the fluorescent ceramic body (doping amount 0.15mol%), MgO is selected as the high thermal conductivity medium ceramic matrix, L is 450 μm, δ was 28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com