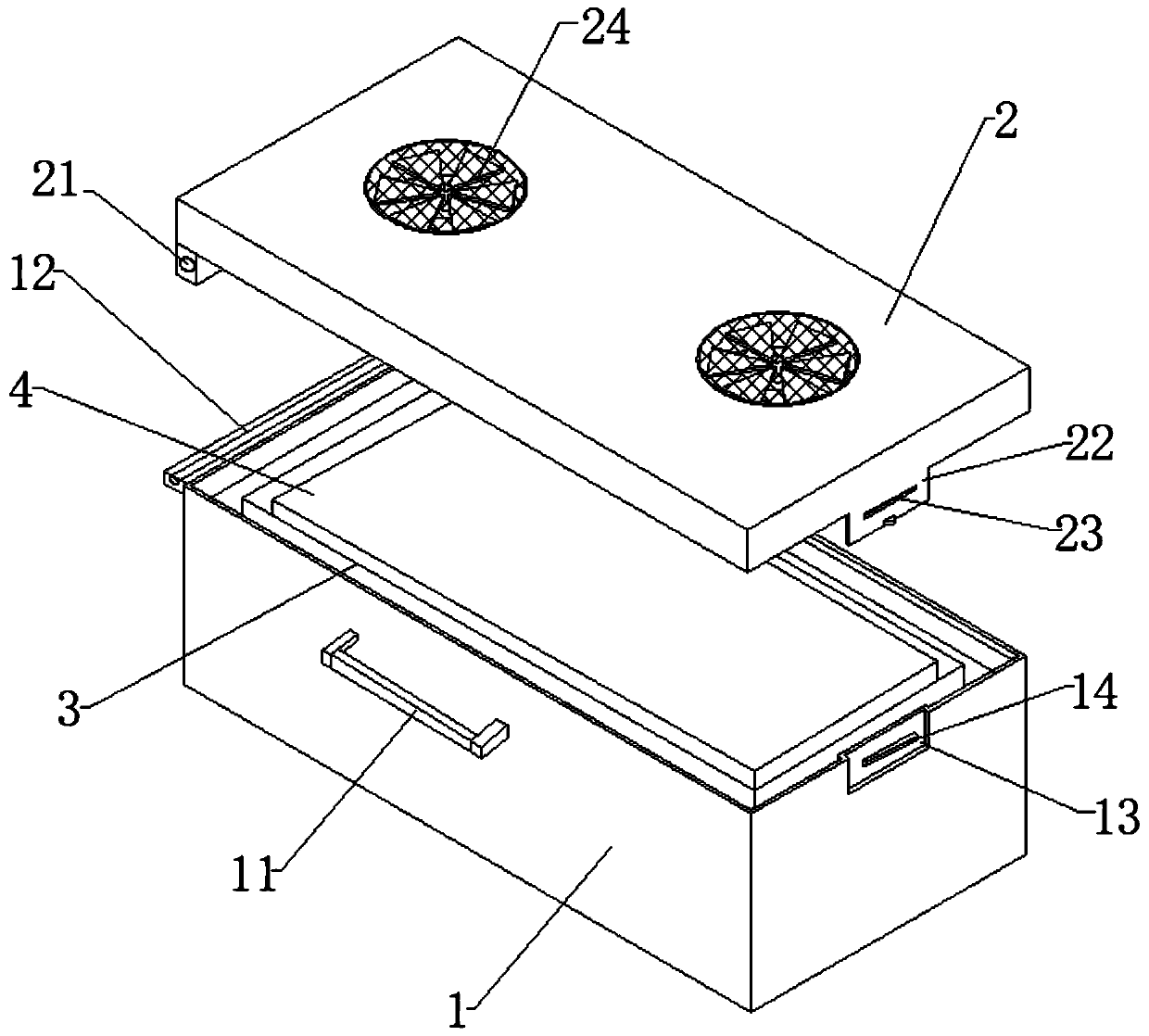

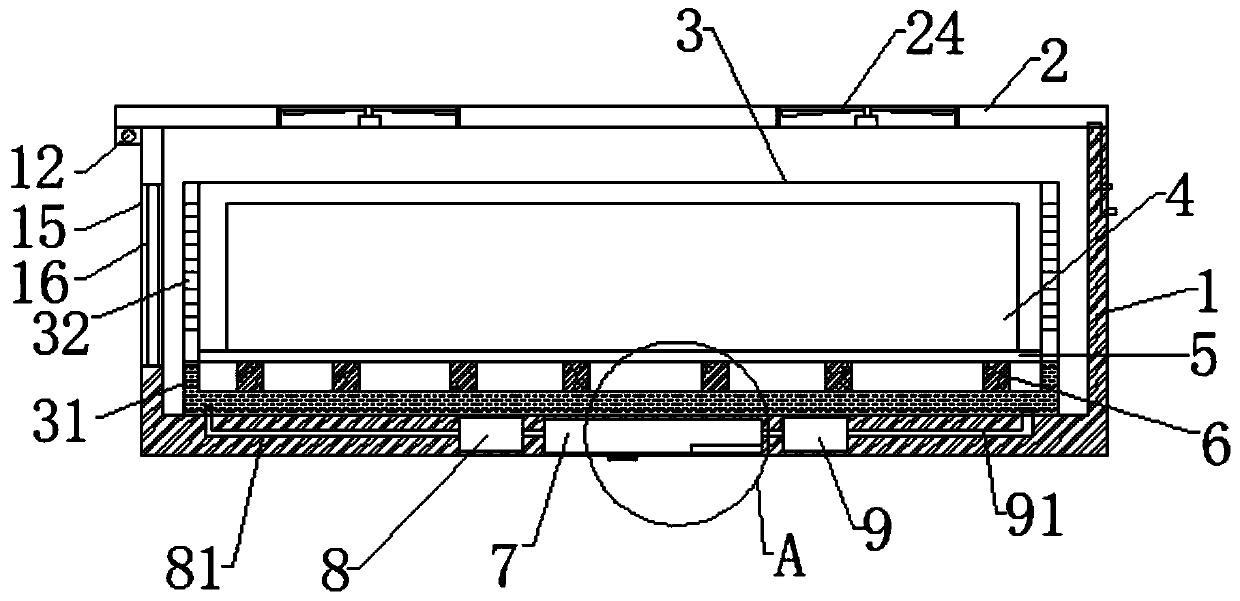

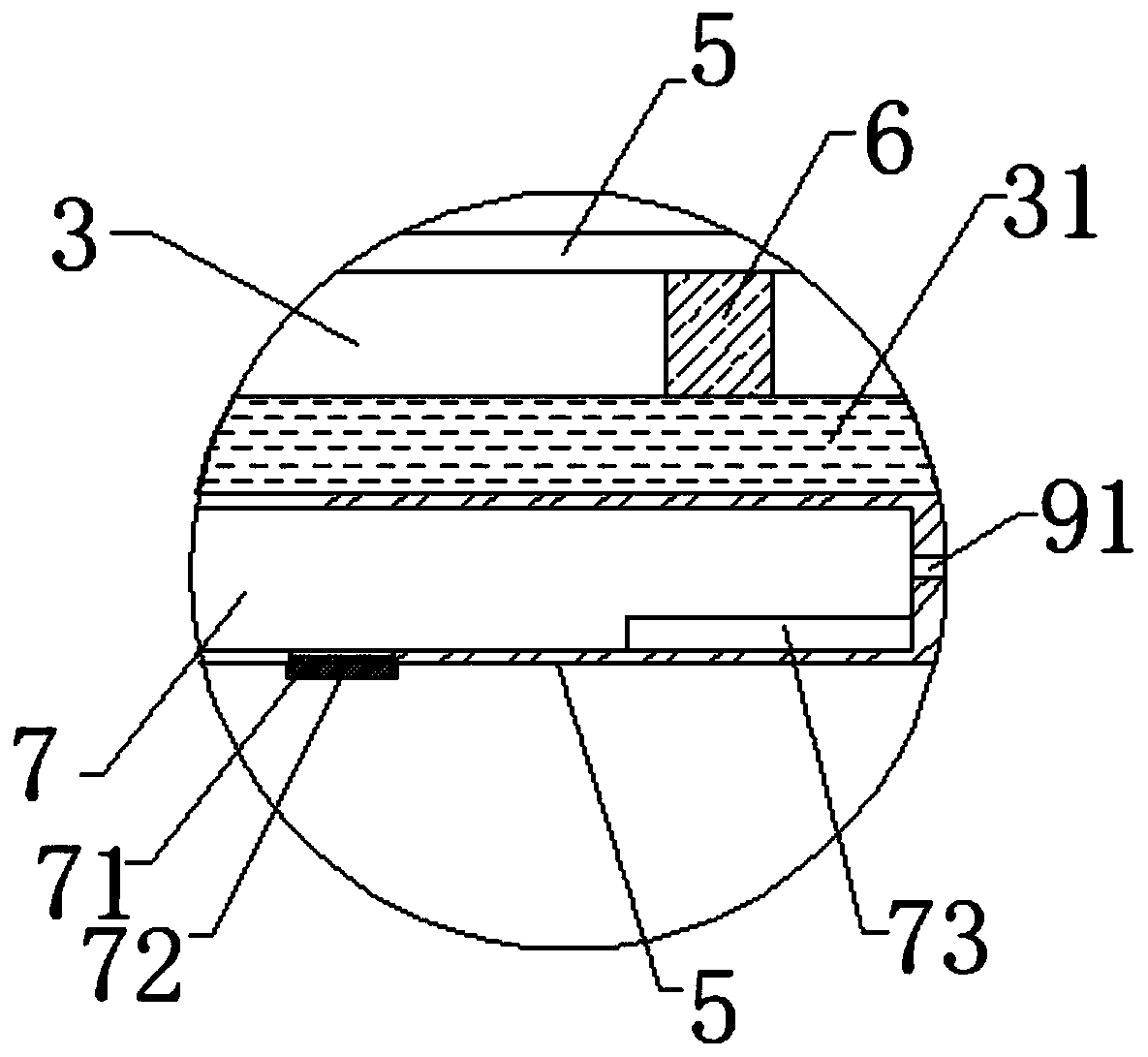

Electric automobile battery pack with good heat dissipation performance

A heat dissipation performance technology for electric vehicles, applied to battery pack components, secondary batteries, battery covers/end covers, etc., can solve problems such as poor heat dissipation, battery failure, battery equipment damage, etc., and achieve long-lasting waterproof effect , improve temperature resistance and waterproof ability, and have a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of described heat dissipation coating, comprises the following steps:

[0051] S1. Add epoxy-modified acrylic resin, graphene, silicon phosphate, fluorinated silicon oil and lubricant into the high mixer, and stir and mix at a speed of 600-900r / min;

[0052] S2. Melting and heating the mixture;

[0053] S3, then the heated mixture is extruded, cooled, and formed into a sheet;

[0054] S4, pulverizing and grinding the flakes to obtain powder particles;

[0055] S5. Electrostatically spray the powder particles on the outer box 1 and the box cover 2 at negative voltage and high voltage.

[0056] The heat dissipation coating comprises the following components in parts by mass:

[0057] 26 parts of epoxy-modified acrylic resin, 3 parts of graphene, 28 parts of silicon phosphate, 11 parts of fluorinated silicon oil and 13 parts of lubricant.

[0058] Working principle and application process of the present invention: when the present invention is in...

Embodiment 1

[0060] The preparation method of heat dissipation coating comprises the following steps:

[0061] S1. Add 26 parts of epoxy-modified acrylic resin, 3 parts of graphene, 28 parts of silicon phosphate, 11 parts of fluorinated silicon oil and 13 parts of lubricant into the high mixer, and stir and mix at a speed of 700r / min;

[0062] S2. Melting and heating the mixture;

[0063] S3, then the heated mixture is extruded, cooled, and formed into a sheet;

[0064] S4, pulverizing and grinding the flakes to obtain powder particles;

[0065] S5, spray the powder particles on the outer box 1 and the box cover 2 under negative voltage and high voltage electrostatic spraying

Embodiment 2

[0067] The preparation method of heat dissipation coating comprises the following steps:

[0068] S1. Add 25 parts of epoxy-modified acrylic resin, 2 parts of graphene, 25 parts of silicon phosphate, 8 parts of fluorinated silicon oil and 10 parts of lubricant into the high mixer, and stir and mix at a speed of 600r / min;

[0069] S2. Melting and heating the mixture;

[0070] S3, then the heated mixture is extruded, cooled, and formed into a sheet;

[0071] S4, pulverizing and grinding the flakes to obtain powder particles;

[0072] S5. Electrostatically spray the powder particles on the outer box 1 and the box cover 2 at negative voltage and high voltage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com