Preparation method of mesoporous MSQ aerogel/glass fiber composite material

A technology of glass fiber and composite materials, applied in the field of thermal insulation materials, to achieve the effect of improving mechanical properties and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

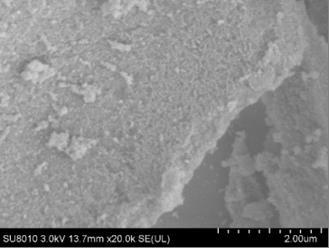

[0030] Embodiment 1: see figure 1

[0031] A preparation method of a mesoporous MSQ airgel / glass fiber composite material containing an infrared shading agent, comprising the following steps:

[0032] 1) Mix and stir 32 g of cetyltrimethylammonium chloride, 100 mL of methyltrimethoxysilane, 250 mL of methanol and 50 mL of hydrochloric acid (0.001 mol / L), then add 250 mL of 1 -2 propylene oxide, stirred for 2 min and then poured into a fixed container to obtain a sol; add 25mL of titanium sol to the sol and fully stir to obtain a composite sol;

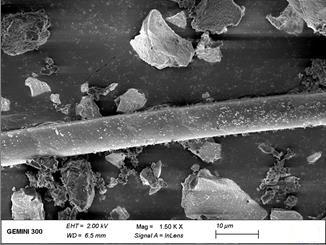

[0033] 2) Completely impregnate the cut high-silica glass fiber mat in the composite sol, transfer the glass fiber mat impregnated with the composite sol into a plastic box and seal it;

[0034] 3) Put the sealed plastic box in a microwave dryer for microwave curing, set the dehumidification rate to 20%, microwave power to 250 W, and curing time to 12 minutes; add methanol to the obtained gel / glass fiber composite material for solven...

Embodiment 2

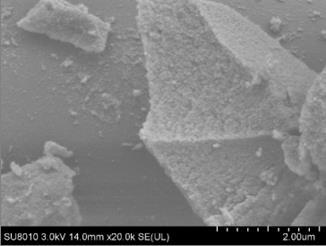

[0037] Embodiment 2: see figure 2

[0038] A preparation method of mesoporous MSQ airgel / glass fiber composite material containing an infrared opacifying agent, the volume of the titanium sol in step 1) in the embodiment is changed to 50mL, and the rest of the steps are the same as in the embodiment 1.

[0039] The prepared mesoporous MSQ airgel / glass fiber composite material containing infrared opacifying agent has abundant pores and uniform morphology, and its thermal conductivity is 0.028 W / (m K) at room temperature and 0.092 W at high temperature (600°C). / (m•K).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com