Metal-plastic composite material sliding bearing and manufacturing method thereof

A composite material, metal-plastic technology, applied in the direction of additive manufacturing, shafts and bearings, bearing components, etc., to achieve the effect of large processing flexibility, guaranteed fixed connection, and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

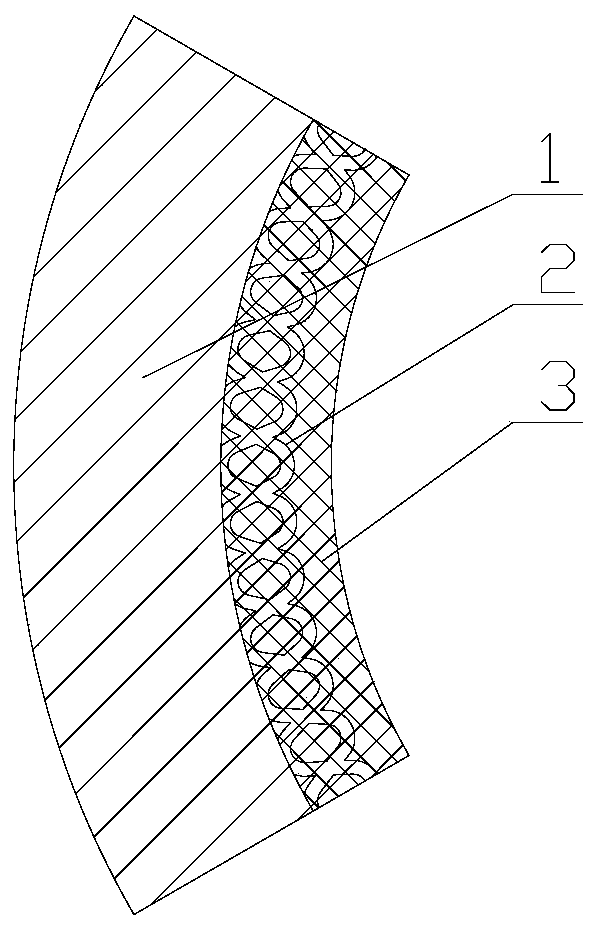

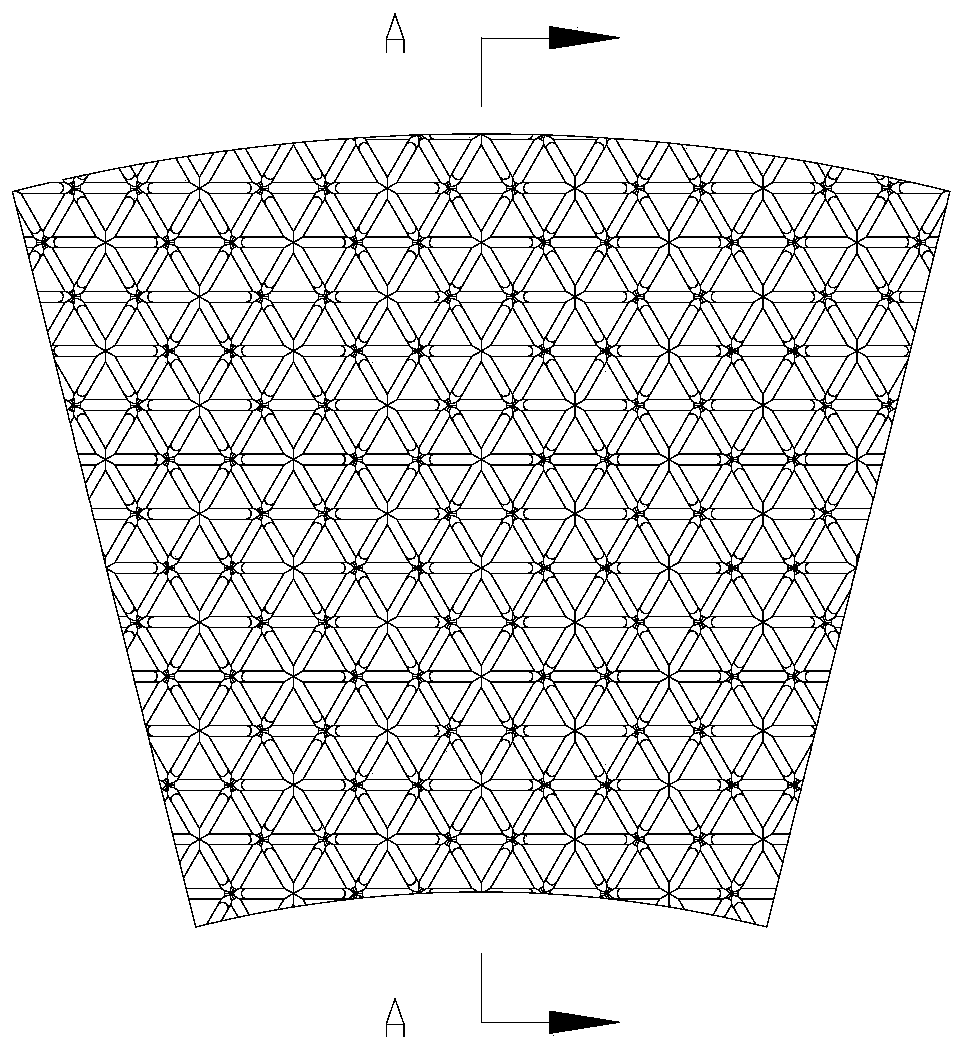

[0072] Such as Figure 1-4 As shown, the metal-plastic composite sliding bearing includes: a fan-shaped steel substrate, a stainless steel network connection layer, and a new heterocyclic high-performance modified engineering plastic resin layer.

[0073] The fan-shaped steel substrate is made of carbon steel or stainless steel, and its shape and size are completed by machining.

[0074] The material of the network connection layer is 316L, 17-4PH stainless steel, its thickness is 3mm, and the structure of the connection layer is as follows: figure 2 As shown, the porosity of the connection layer is 80%, and the diameter of the network connection wire is 0.5 mm. The network connection layer is formed on the connection surface of the fan-shaped steel substrate by metal 3D printing technology. The stainless steel powder particle size is 15-20 μm, the laser spot diameter is 90 μm, and the average thickness of the powder layer is 30 μm. After the connecting layer is formed, san...

Embodiment 2

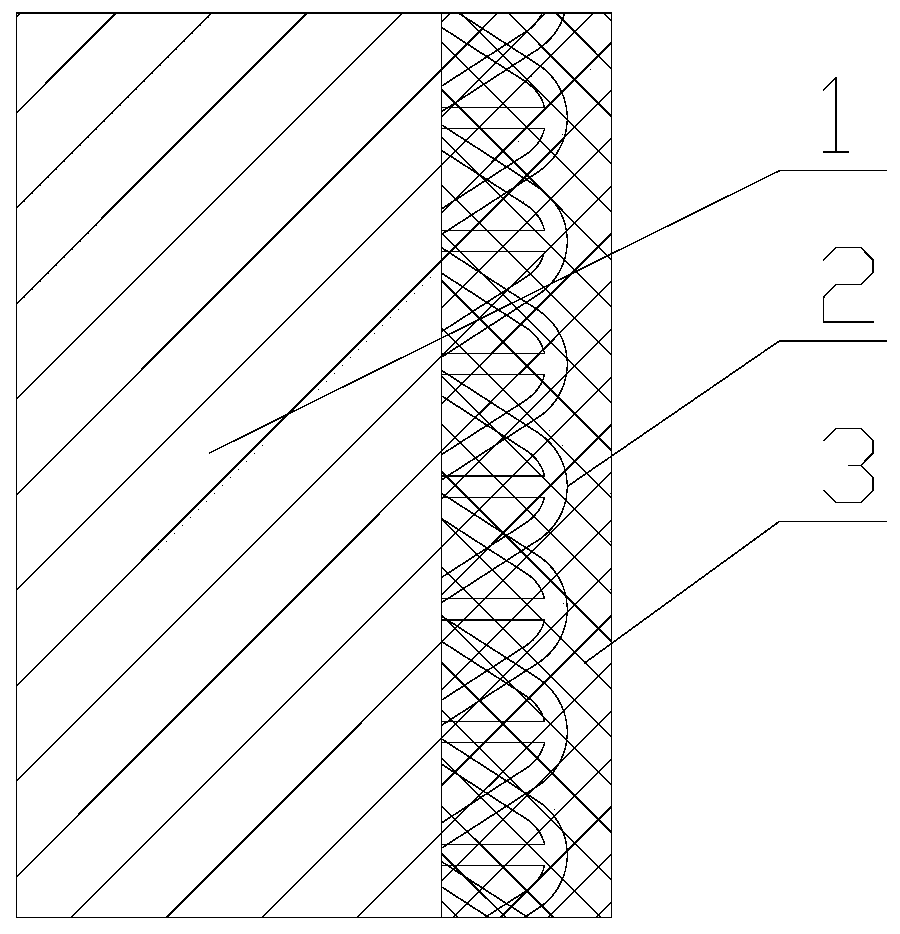

[0085] Such as figure 1 , 2, 5, and 6, (on the basis of Example 1), the metal-plastic composite material thrust bearing includes: a fan-shaped steel substrate, a bronze alloy network connection layer, and a modified polyetheretherketone engineering plastic resin layer.

[0086] The material of the network connection layer is CuSn10 bronze alloy, its thickness is 5mm, and the structure of the connection layer is as follows: image 3 As shown, the porosity of the connecting layer is 60%, and the diameter of the network connecting wire is 1 mm. The connection layer is formed on the connection surface of the fan-shaped steel substrate by metal 3D printing technology, using bronze alloy powder with a particle size of 50-80 μm, a laser spot diameter of 100 μm, and an average thickness of the powder layer of 60 μm. After the connecting layer is formed, sandblasting is required to complete the manufacturing of the connecting layer.

[0087] The new heterocyclic high-performance mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com