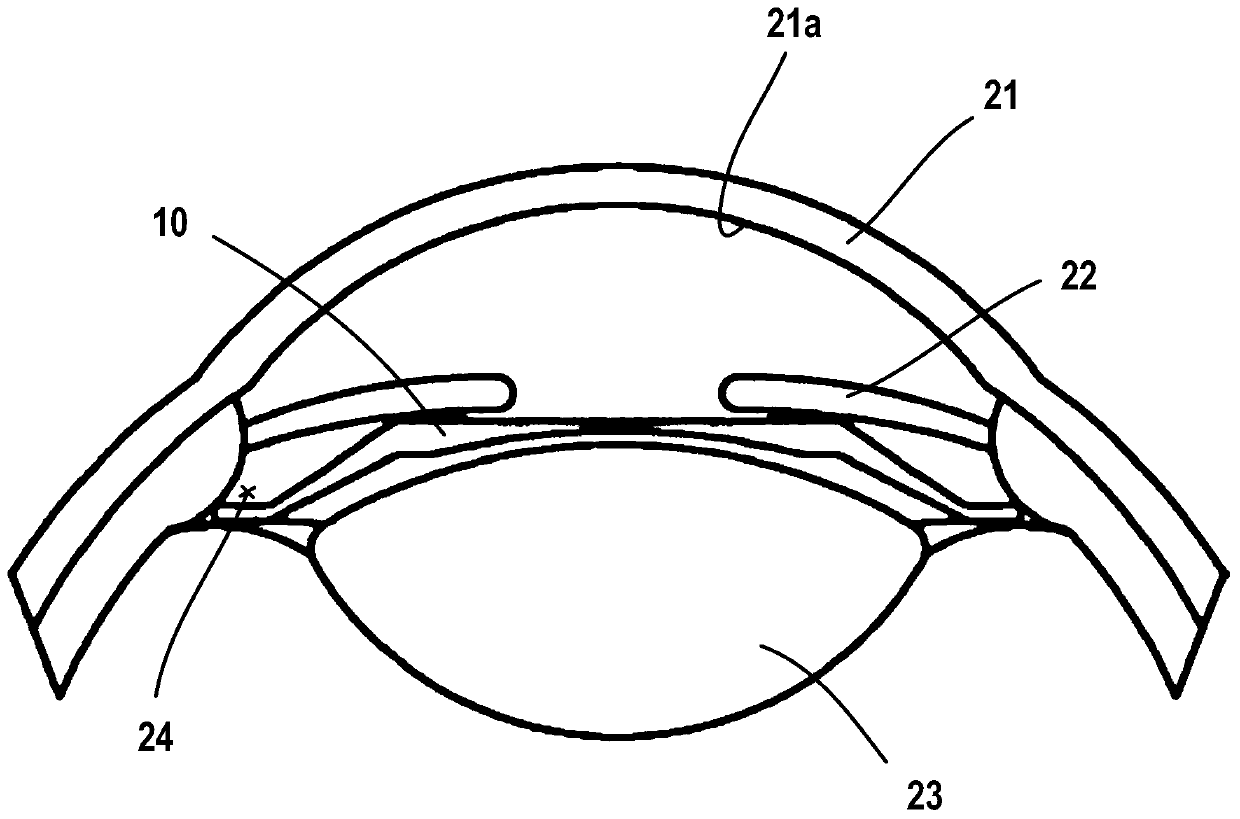

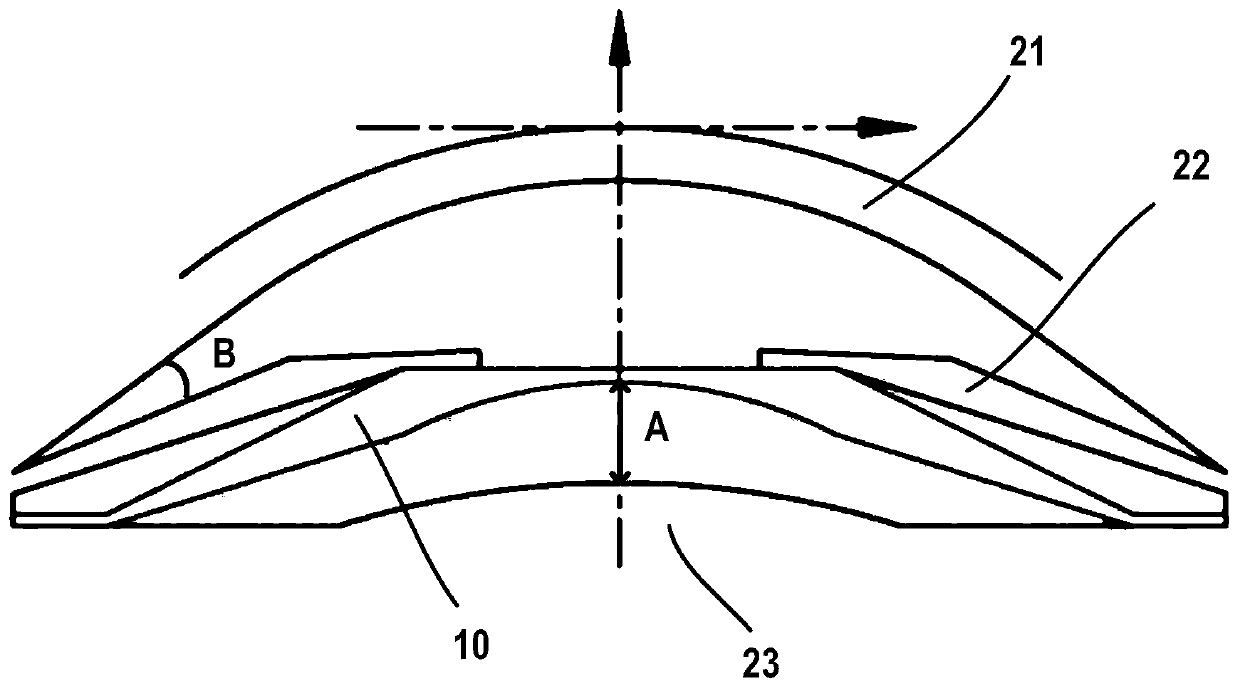

Phakic intraocular lens

A technology of intraocular lens and crystalline lens, applied in the direction of intraocular lens, ocular implants, etc., can solve the problems of high pre-judgment of patients' postoperative safety problems, safety hazards, etc., and achieve the effect of excellent deformation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] 1) Preparation method of the material

[0062] The preparation method of the material is a relatively conventional method, which is briefly described here. All example materials were prepared as follows and all monomers were purified by distillation under reduced pressure. In a 250ml beaker, mix acrylate monomers in corresponding proportions, including but not limited to hydroxyethyl methacrylate (HEMA), ethyl acrylate (EA), ethyl methacrylate (EMA), acrylic acid- 2-Phenoxyethyl acrylate (POEA), butyl acrylate (BA), hydroxyethyl acrylate (HEA), phenylethyl acrylate (PEA), phenylethyl methacrylate (PEMA), benzyl methacrylate Ethyl ethyl ester (BMA), ethoxy ethyl methacrylate (EOEMA), ethoxy ethoxy ethyl acrylate (EOEOEA) and ethylene glycol dimethacrylate (EGDMA), butylene glycol diacrylate (BDDA), etc., and add initiator and light absorber, fully stir and filter, transfer to a special mold.

[0063]The various utensils and molds used in the above implementation proce...

Embodiment 1

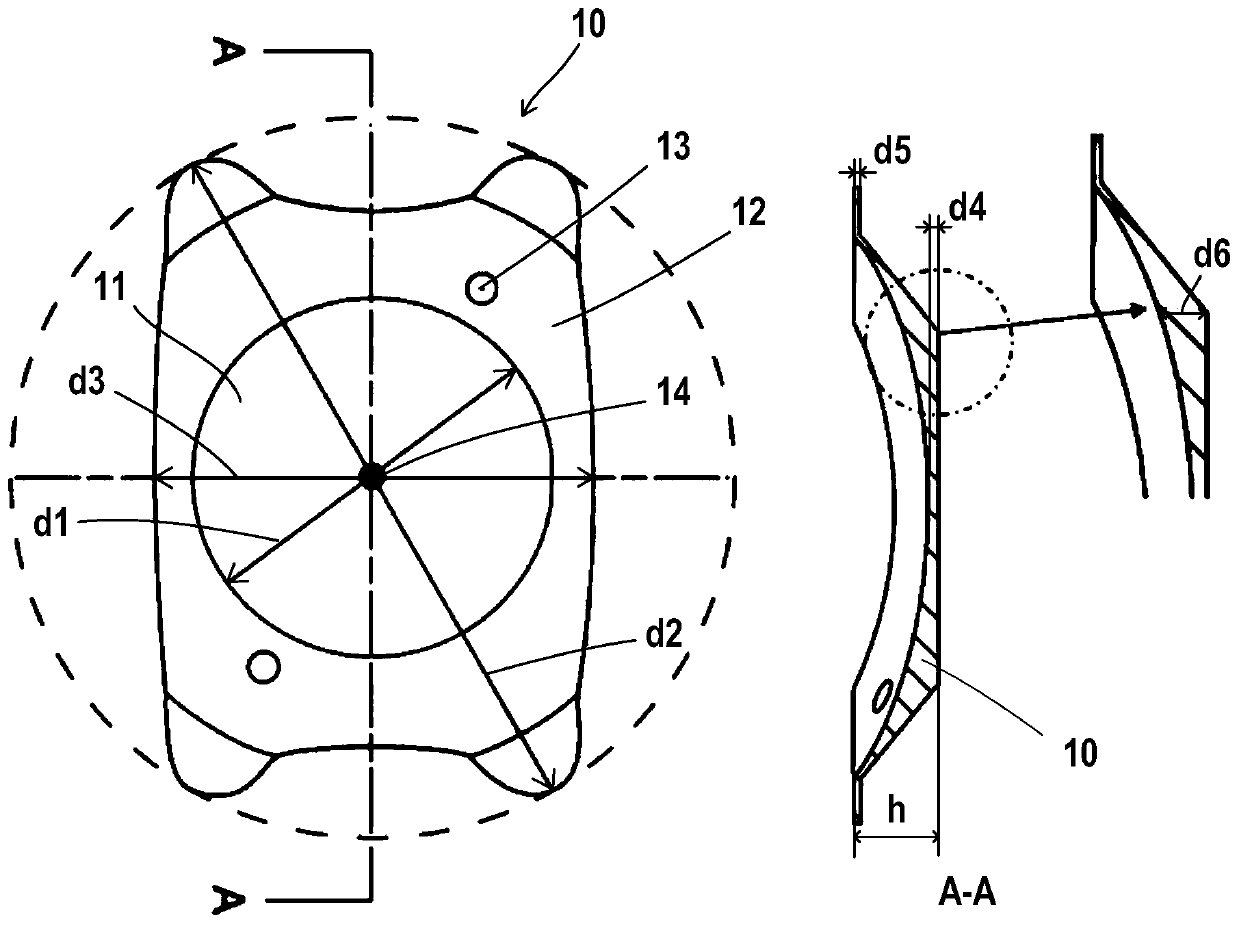

[0069] A hydrophilic acrylate material having a refractive index of 1.502 and a water content of 8% was used. The material has a Young's modulus of elasticity of 1.25 MPa. This material is used to make intraocular lenses, and the specific design parameters are shown in Table 1.

[0070] Table 1 Intraocular lens design parameters

[0071]

[0072] where Ra is the radius of curvature of the front surface of the crystal, and Rp is the radius of curvature of the rear surface of the crystal.

[0073] There are phakic intraocular lenses with the above specifications, and 5 pieces are made for each diopter. After being fully hydrated, different pressures are applied to the phakic intraocular lenses in the horizontal direction and the axial direction respectively. The pressure is read by an electronic balance, and the unit is Gram (g), Table 2 shows the measured results, that is, the axial displacement of the intraocular lens under different pressures applied in the horizontal di...

Embodiment 2

[0077] A hydrophobic acrylate material having a refractive index of 1.55 was used. The material has a Young's modulus of elasticity of 2.0 MPa. Use this material to make intraocular lenses with different specifications, and the specific design parameters are shown in Table 3.

[0078] Table 3 Intraocular lens design parameters

[0079]

[0080] where Ra is the radius of curvature of the front surface of the crystal, and Rp is the radius of curvature of the rear surface of the crystal.

[0081] There are phakic intraocular lenses with the above specifications, and 5 are made each. After fully hydrating, different pressures are applied to the phakic intraocular lenses in the horizontal direction and the axial direction respectively. The pressure is read by an electronic balance, and the unit is grams (g ), Table 4 shows the measured axial displacement of the intraocular lens under different pressures applied in the horizontal direction and axial direction. It can be seen f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com