Composite material negative ion release head and preparation method thereof, and negative ion generation electrode

A composite material and negative ion technology, applied in electrical components and other directions, can solve the problems of release head performance impact, user fear, service life impact, etc., and achieve the effects of improving directional transmission, increasing release concentration, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

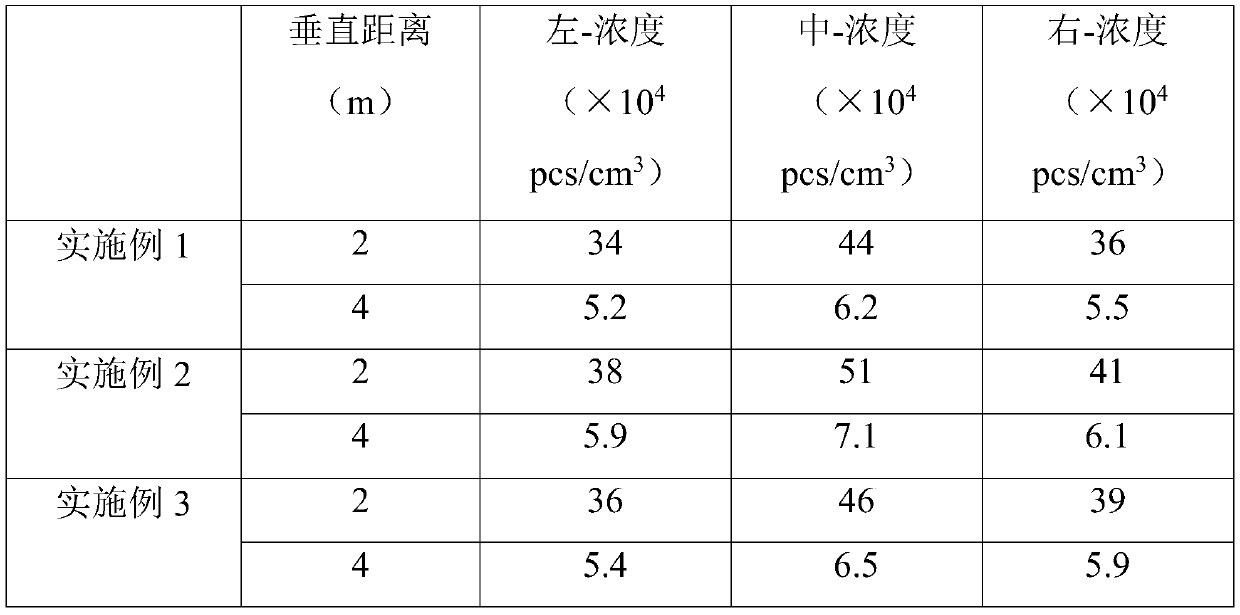

Embodiment 1

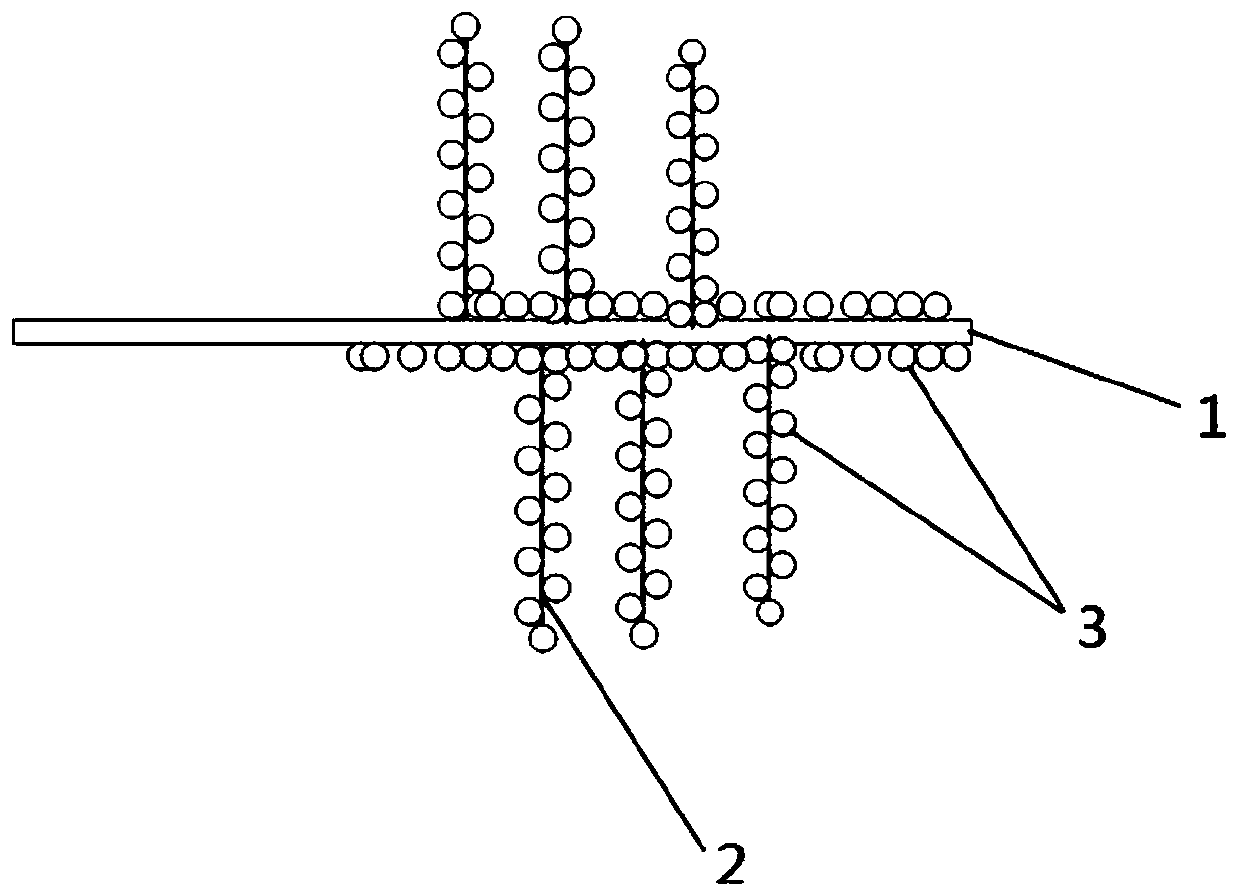

[0097] The method for preparing the composite negative ion release head of the present embodiment comprises:

[0098] S1: Ultrasonic cleaning the titanium wire in acetone, absolute ethanol and deionized water in sequence, the power of ultrasonic cleaning is 200W, the time is 10 minutes, and then dried with high-purity nitrogen with a purity of 99.9%;

[0099] S2: An aluminum layer with a thickness of 2.5 μm is plated on the surface of the titanium wire by evaporation;

[0100] S3: Soak the titanium wire coated with aluminum layer in HF solution with a mass fraction of 5% for 5 minutes, and then dry the titanium wire under nitrogen atmosphere;

[0101] S4: annealing the titanium wire obtained in step S3 at 400° C. for 30 minutes in an air atmosphere;

[0102] S5: Place the titanium wire obtained in step S4 in a reaction furnace, vaporize the toluene solution of ferric chloride at 300° C. to form a toluene flow of ferric chloride, and flow the After the toluene flow of ferric ...

Embodiment 2

[0107] The method for preparing the composite negative ion release head of the present embodiment comprises:

[0108] S1: Ultrasonic cleaning the molybdenum wire in acetone, absolute ethanol and deionized water in sequence, the ultrasonic cleaning power is 400W, the time is 8 minutes, and then dried with high-purity nitrogen with a purity of 99.9%;

[0109] S2: Soak the dried molybdenum wire in HF solution with a mass fraction of 7% for 3 minutes, and then dry the molybdenum wire under a helium atmosphere;

[0110] S3: Place the molybdenum wire obtained in step S2 in a reaction furnace, mix the methanol solution of nickel nitrate with xylene (the molar ratio of xylene to nickel nitrate is 125:1), and then gasify at 150° C. to form a mixed gas flow, With the flow rate of 404ml / min, the mixed gas is flowed into the reaction furnace, and nitrogen and hydrogen are passed into the reaction furnace at the flow rate of 2300ml / min and 250ml / min simultaneously, and the temperature of t...

Embodiment 3

[0115] The method for preparing the composite negative ion release head of the present embodiment comprises:

[0116] S1: Ultrasonic cleaning the tungsten wire in acetone, absolute ethanol and deionized water in sequence. The power of ultrasonic cleaning is 600W for 5 minutes, and then blow dry with high-purity nitrogen gas with a purity of 99.9%.

[0117] S2: Coating a molybdenum layer with a thickness of 0.5 μm on the surface of the tungsten wire by magnetron sputtering;

[0118] S3: Soak the tungsten wire coated with molybdenum in HF solution with a mass fraction of 10% for 2 minutes, and then dry the tungsten wire under a neon gas atmosphere;

[0119] S4: annealing the tungsten wire obtained in step S3 at 600° C. for 20 minutes in an air atmosphere;

[0120] S5: Place the tungsten wire obtained in step S4 in a reaction furnace, mix the toluene solution of cobalt sulfate with isopropanol (the molar ratio of isopropanol to cobalt sulfate is 130:1), and then vaporize at 400°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com