On-site microwave rock breaking simulation system and simulation method

A simulation system, microwave technology, applied in mining, geotechnical engineering, and tunnel fields, can solve problems such as difficult to effectively guide microwave rock breaking work, inaccurate simulation of on-site working conditions, and failure to consider the impact of confining pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

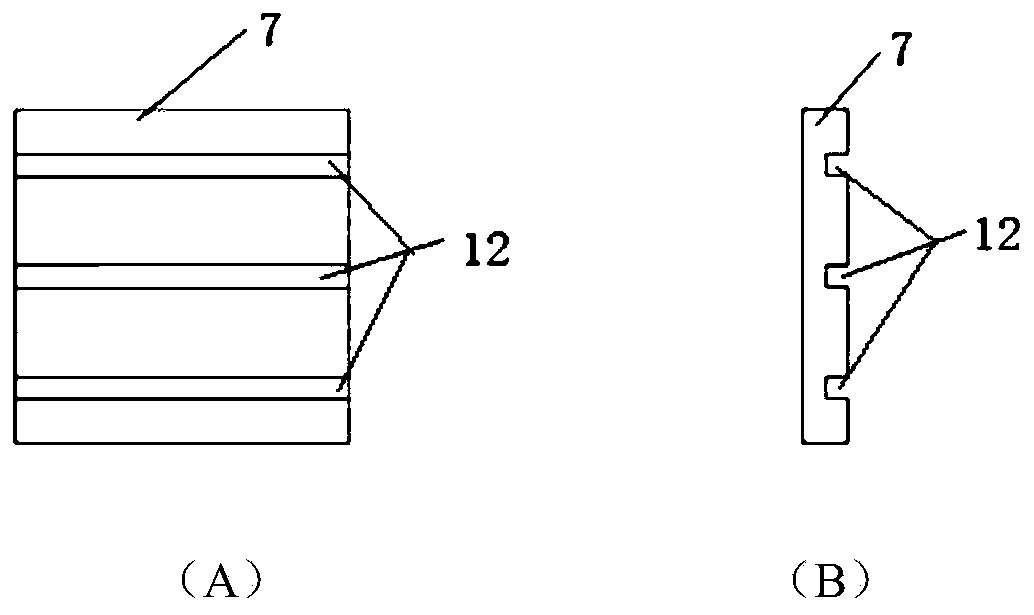

[0044] The on-site microwave rock-breaking simulation system described in this embodiment includes a microwave source 1, a waveguide 2, a circulator 3, a water load 4, a rock-breaking test chamber 5, a microwave blocking and confining pressure loading system, and a data acquisition system. The microwave source is a solid-state microwave source with a water-cooled structure, and the water load also has a water-cooled structure. When the microwave source and the water load are working, flowing cold water should be introduced into their water-cooled structure to prevent the equipment from being overheated and damaged. Water loads can be purchased directly from the market.

[0045] One end of the waveguide 2 is connected to the microwave exit port of the microwave source 1, and the other end is connected to the microwave entrance port of the circulator 3. The microwave exit port of the circulator 3 is connected to the microwave entrance port of the rock-breaking test chamber 5. Th...

Embodiment 2

[0049] In this embodiment, the simulation system described in Embodiment 1 is used to simulate on-site microwave rock breaking, including the following steps:

[0050] S1: Paste the sensor on the surface of the rock sample, open the door of the rock-breaking test chamber, and place the rock sample with the sensor on the surface on the microwave blocking front plate located below the rock-breaking test chamber. Adjust the height of the microwave blocking front plate on which the rock sample is placed, so that the microwave irradiation surface of the rock sample faces the microwave entrance of the rock-breaking test chamber; adjust the microwave blocking front plate above the rock sample to be close to the rock sample. The upper surface of the sample is attached; adjust the positions of the other three microwave blocking positive plates so that they are respectively attached to the other three surfaces of the rock sample and expose the microwave irradiation surface.

[0051]In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com