Terpolymer and preparation method of electric storage device thereof

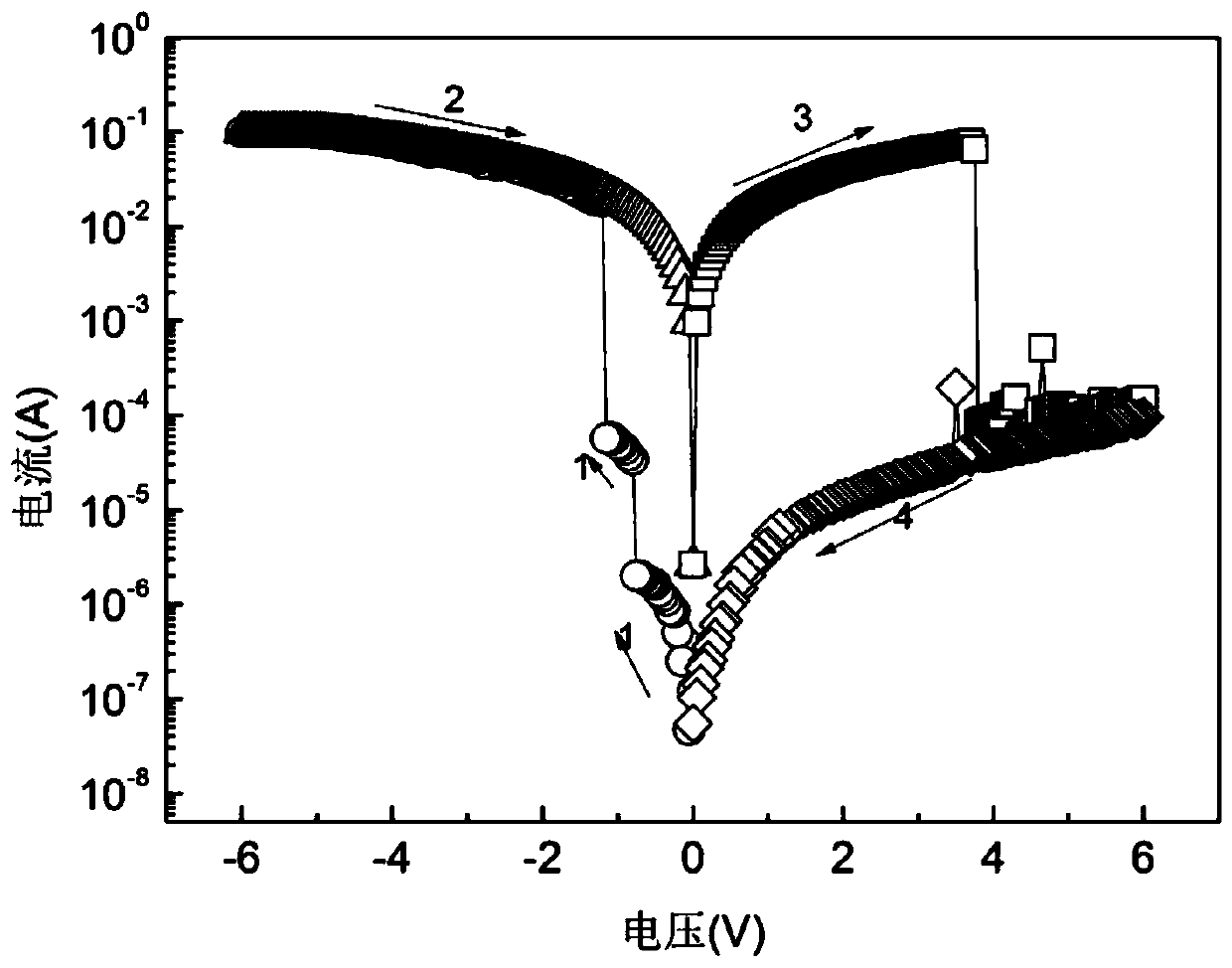

A technology of terpolymers and polymers, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of complex and difficult preparation methods, high turn-on voltage, etc., and achieve easy realization of the preparation process and industrialization production, the effect of high switching current ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the carbazole-fluorene-benzimidazole terpolymer includes the following steps:

[0054] Step 1. Add the halogenated carbazole monomers, halogenated benzimidazole monomers and fluorene monomers to a solvent, and heat to react to obtain a polymer solution.

[0055] The halogenated carbazole monomer is a halogenated N-alkylcarbazole, and the alkyl group is an alkyl group containing 3 to 31 carbon atoms, preferably an alkyl group containing 6 to 21 carbon atoms, and more preferably 7 -Tridecyl, 8-pentadecyl and 9-heptadecyl.

[0056] Preferably, the 2 and 7 positions of the halogenated carbazole monomer are substituted by halogen, and the halogen is selected from chlorine, bromine, and iodine, preferably bromine or iodine.

[0057] The carbazole group has good hole transport properties, at the same time, it has active modification points, and the structure has strong flexibility. Azo as a bridge bond can introduce other groups, and the storage of electrical...

Embodiment 1

[0129] In N 2 In the atmosphere, put 1.49 g of 2,3-naphthalenedicarboxylic acid anhydride, 0.27 g of 3,6-dibromo-1,2-phenylenediamine, and 10 mL of glacial acetic acid into the reaction vessel, stir and warm up to 108°C, the solvent refluxed, Constant temperature reaction for 6 hours.

[0130] After the reaction, the reaction solution was cooled to room temperature, and after the crude product gradually precipitated, it was filtered and washed with deionized water to neutrality. Put the obtained crude product into a vacuum drying oven for drying, the temperature of vacuum drying is 85° C., the time of vacuum drying is 12 hours, and the pressure of vacuum drying is -30KPa. The dried crude product is separated and purified by column chromatography. The stationary phase of the chromatography column is silica gel powder, and the liquid phase is dichloromethane: petroleum ether (3:1) to obtain benzimidazole monomer 1,4-di Bromo-12H-benzo[5,6]isoindolo[2,1-a]benzimidazole-12-one.

[01...

Embodiment 2

[0135] The substrate layer with the ITO cathode layer was sequentially washed in deionized water, absolute ethanol, acetone, absolute ethanol, and deionized water for 30 minutes each, and then stored in absolute ethanol after washing.

[0136] The terpolymer prepared in Example 1 was dissolved in toluene to obtain a polymer solution with a concentration of 5 mg / mL. The above polymer solution is dropped on the cleaned cathode layer, uniformly dispersed by a homogenizer, and the toluene solvent is removed by vacuum drying to obtain an organic layer with a thickness of 250 nm.

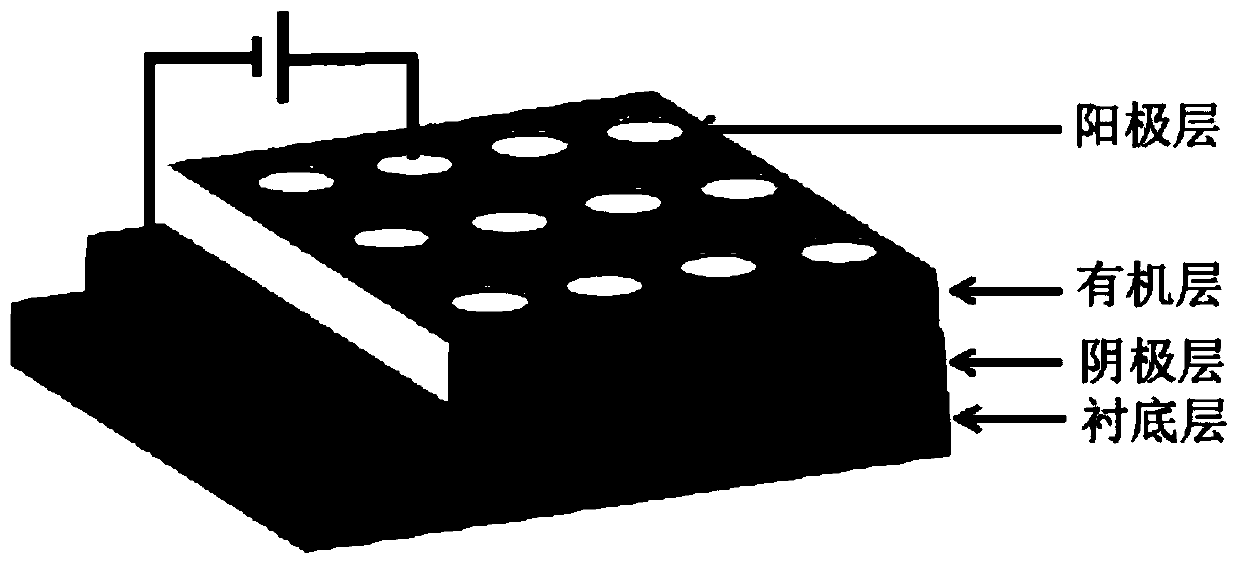

[0137] The metal electrode Al is attached to the organic layer by vacuum evaporation method. The thickness and area of the metal electrode are 300nm and 1.0mm, respectively 2 . Obtain a sandwich structure organic electric storage device of Flash storage type, the structure diagram is as follows figure 1 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com