High-temperature and high-pressure resistant solvent-free heavy anti-corrosion paint and preparation method thereof

A solvent-free, high-temperature-resistant technology, applied in anti-corrosion coatings, fire-retardant coatings, epoxy resin coatings, etc., can solve problems such as reduced pressure bearing capacity, slow solvent volatilization, cracking, etc., to improve transportation safety, good hardness and Abrasion resistance, effect of improving erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A solvent-free heavy-duty anti-corrosion coating resistant to high temperature and high pressure,

[0022] High temperature and high pressure solvent-free heavy-duty anti-corrosion coating, which includes the following components by weight: 40 parts of novolak epoxy resin, 5 parts of bisphenol F resin, 5 parts of reactive toughening agent, 8 parts of reactive diluent, 2 parts of thixotropic agent, 10 parts of heat-resistant pigment, 1 part of additive, 10 parts of filler, 20 parts of curing agent.

[0023] The reactive toughening agent is 172 modified resin.

[0024] The reactive diluent is a reactive environment-friendly diluent polyethylene glycol diglycidyl ether.

[0025] The thixotropic agent is polyamide wax powder and organic bentonite.

[0026] The heat-resistant pigment is chromium oxide green.

[0027] The additives mentioned are dispersant 598, defoamer 1799 and leveling agent 3701.

[0028] The filler is 1250 mesh silica powder.

[0029] T...

Embodiment 2

[0030] Embodiment 2: A solvent-free heavy-duty anti-corrosion coating resistant to high temperature and high pressure,

[0031] High temperature and high pressure solvent-free heavy-duty anti-corrosion coating, which includes the following components by weight: 50 parts of novolak epoxy resin, 8 parts of bisphenol F resin, 10 parts of reactive toughening agent, 8 parts of reactive diluent, 3 parts of thixotropic agent, 8 parts of heat-resistant pigment, 2 parts of additive, 8 parts of filler, 25 parts of curing agent.

[0032] The reactive toughening agent is 172 modified resin.

[0033] The reactive diluent is a reactive environment-friendly diluent polyethylene glycol diglycidyl ether.

[0034] The thixotropic agent is polyamide wax powder and organic bentonite.

[0035] The heat-resistant pigment is chromium oxide green.

[0036] The additives mentioned are dispersant 598, defoamer 1799 and leveling agent 3701.

[0037] The filler is 1250 mesh silica powder.

[0038] T...

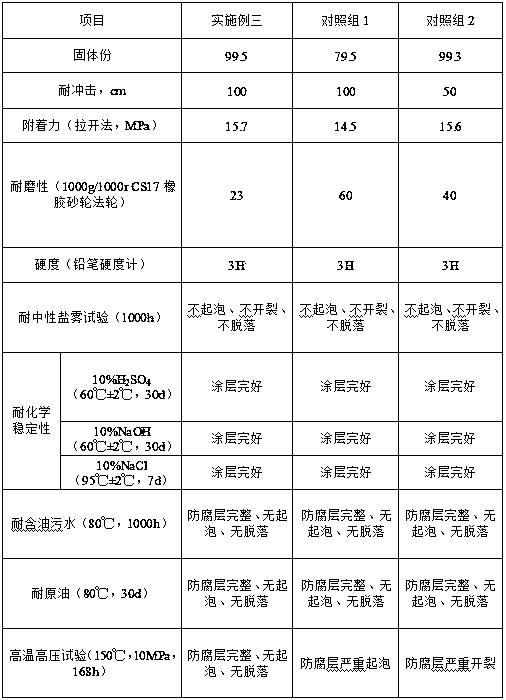

Embodiment 3

[0039] Embodiment 3: A solvent-free heavy-duty anti-corrosion coating resistant to high temperature and high pressure,

[0040] High temperature and high pressure solvent-free heavy-duty anti-corrosion coating, which includes the following components by weight: 55 parts of novolak epoxy resin, 10 parts of bisphenol F resin, 10 parts of reactive toughening agent, 10 parts of reactive diluent, 3 parts of thixotropic agent, 5 parts of heat-resistant pigment, 2 parts of additive, 5 parts of filler, 30 parts of curing agent.

[0041] The reactive toughening agent is 172 modified resin.

[0042] The reactive diluent is a reactive environment-friendly diluent polyethylene glycol diglycidyl ether.

[0043] The thixotropic agent is polyamide wax powder and organic bentonite.

[0044] The heat-resistant pigment is chromium oxide green.

[0045] The additives described are dispersant 598, defoamer 1799, and leveling agent 481.

[0046] The filler is 1250 mesh silica powder.

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com