A method for the co-catalytic conversion of methane and ethane into olefins, aromatics and hydrogen

A technology for producing ethane and methane, which is applied in chemical instruments and methods, catalyst activation/preparation, hydrogen/synthesis gas production, etc., and can solve the problems of harsh catalyst preparation conditions, low selectivity, and large catalyst bed pressure drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] 1. Preparation of catalytic reactor (thin layer thickness and active component content need to be indicated)

[0063] The preparation method of the lattice doped catalyst includes chemical vapor deposition (MCVD) coating solid-phase doping technology or solid-liquid phase sol-gel combined with high-temperature melting coating technology. Membrane catalysts are marked as:

Embodiment 1

[0066] Modified Chemical Vapor Deposition (MCVD)

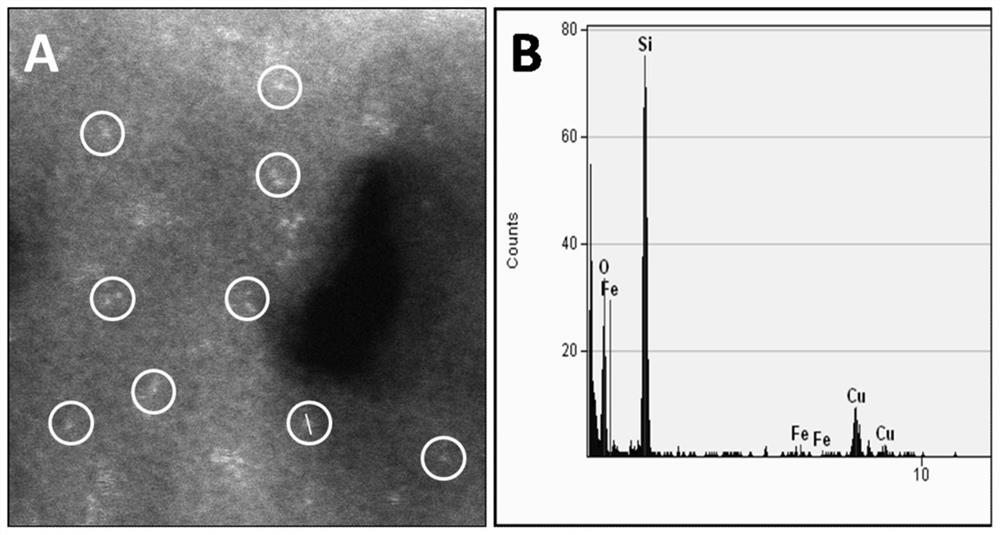

[0067] Use 30mL / min of high-purity oxygen to SiCl 4 Liquid and FeCl under saturated vapor pressure at 350°C using 200mL / min high-purity helium 3 The gas is brought into the high-temperature MCVD device, and the contact surface of the quartz tube (wall thickness 1.5mm) with an outer diameter of 20mm and a length of 100mm is SiCl at 1600°C 4 and FeCl 3 After 10 min of oxide deposition, Fe-doped SiO was obtained 2 The powder material is then melted for 40 minutes at a temperature of 1980°C under a 2bar high-purity helium atmosphere to form a thin layer of dopant with a thickness of 100nm on the contact surface of the reactor, and then naturally cooled to obtain a diameter of 20mm and a length of 100mm of Catalytic quartz reactor, wherein Fe doping amount is 0.05wt.%.

Embodiment 2

[0069] Modified Chemical Vapor Deposition (MCVD)

[0070] Use 30mL / min of high-purity oxygen to SiCl 4 Liquid and FeCl under saturated vapor pressure at 350°C using 650mL / min high-purity helium 3 The gas is brought into the high-temperature MCVD device, and the inner wall of the quartz tube (wall thickness 1.5mm) with an outer diameter of 20 mm and a length of 100 mm is heated at 1600 ° C by SiCl 4 and FeCl 3 After 10 min of oxide deposition, Fe-doped SiO was obtained 2 The powder material is then melted for 40 minutes at a temperature of 1980°C under a 2bar high-purity helium atmosphere to form a thin layer of dopant with a thickness of 100nm on the contact surface of the reactor, and then naturally cooled to obtain a diameter of 20mm and a length of 100mm of Catalytic quartz reactor, wherein Fe doping amount is 0.1wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com