Method for predicting average diameter of energy-gathered jet flow of metal shaped charge liner material and application thereof

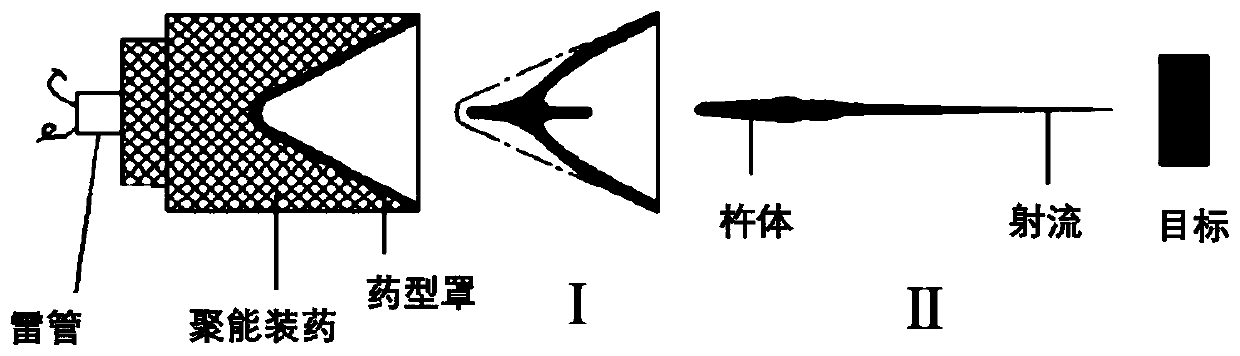

A technology of average diameter and prediction method, applied in the field of engineering blasting, can solve the problem of not considering the influence of the jet shape, and achieve the effect of improving the accuracy and improving the optimization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

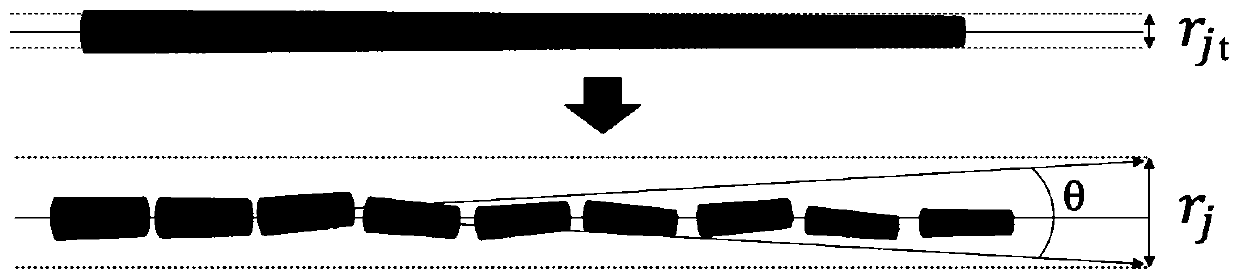

Method used

Image

Examples

Embodiment 1

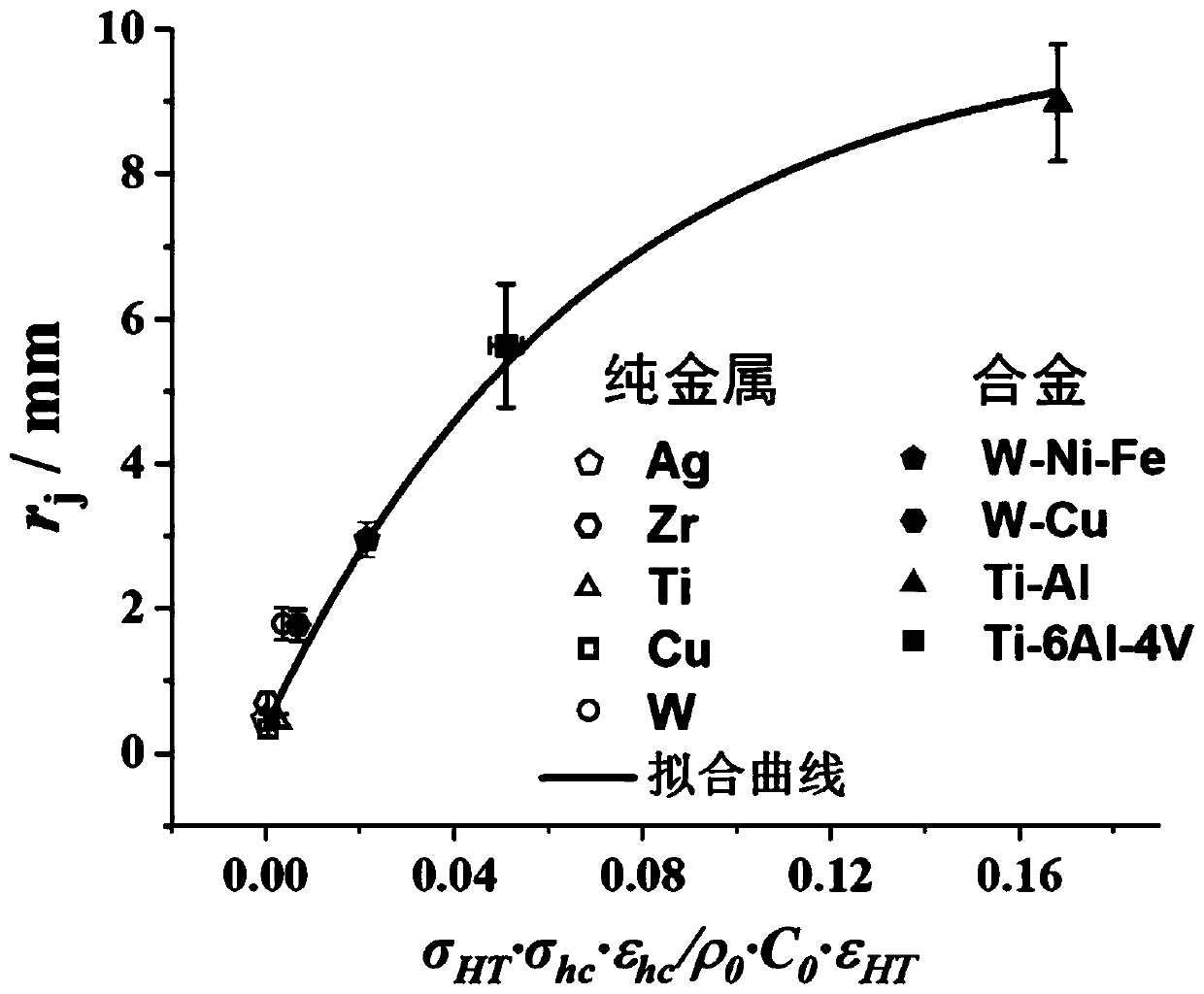

[0157] The predicted diameter is 72mm, the wall thickness is 2mm, and the cone angle is the jet average diameter of the oil perforating ammunition cover material of 72°, and the material to be tested is Ti alloy.

[0158] Obtain the high strain rate compressive strength and high strain rate compression fracture strain of the material to be tested through the separated Hopkinson pressure bar (SHPB), the cross-sectional dimensions and the used The material is the same, the cross-sectional diameter is 14.5mm, the elastic modulus of the material is 197.08GPa, and the sound velocity of the longitudinal wave of the material is 5000m / s; the material is processed into a cylindrical sample of Φ4mm×4mm, and the size is Φ14.5mm×150mm driven by 1.2MPa air pressure The cylindrical bullet hits the incident rod, and the measured sample is in the compression state with an average strain rate of 10750 / s, the high strain rate compressive strength is 1200MPa, and the high strain rate compression ...

Embodiment 2

[0164] The predicted diameter is 72mm, the wall thickness is 2mm, and the cone angle is the jet average diameter of the oil perforating ammunition cover material of 72°, and the material to be tested is Cu alloy.

[0165] According to the method test of embodiment 1, the material property data of the material to be tested is as follows: high strain rate compressive strength 700MPa, high strain rate compression fracture strain 0.45, high temperature tensile strength 150MPa, high temperature tensile fracture strain 0.094, longitudinal wave velocity 4423m / s and density 15.35g / cm 3 , the initial volume of the medicine mask is 20.4cm 3 , Substituting the above material property values into the formula II-2, the average diameter of the jet is calculated to be 1.92mm.

[0166] The X-ray diagram of the jet flow process of petroleum perforating ammunition cover material in the present embodiment is as follows Figure 5 As shown, the diameter of the middle part of the jet is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com