Supramolecular multi-polymer type clean slick-water

A multi-copolymer and supramolecular technology, applied in the field of oil field fracturing, can solve the problems of fracturing effect, poor temperature resistance of vegetable gum cellulose, and poor stability, so as to be beneficial to the control of fracture height and the realization of oil reservoirs. Long penetration, rheological curve without protrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A supramolecular multi-polymer copolymer type clean fracturing fluid is composed of the following components according to the corresponding mass percentages:

[0036] Supramolecular active polymer 0.05%

[0037] Water 99.95%

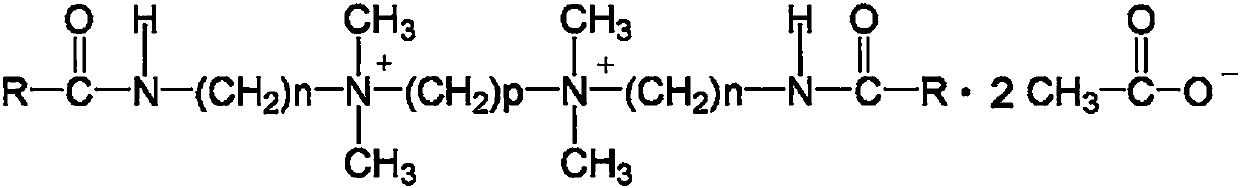

[0038] Wherein, the molecular formula of supramolecular active polymer is as follows:

[0039]

[0040] In the formula, R is a C13-C21 linear or branched alkyl group, n is an integer of 3-6, and p is an integer of 2-4.

[0041] Supramolecular active polymer is obtained by the following steps in the present embodiment:

[0042] 1) Accurately weigh 30-45 grams of acrylamide, 5-10 grams of N-vinylpyrrolidone, 1-2 grams of cetyl acrylate, 2-3 grams of 2-acrylamide-2-methylpropanesulfonic acid (AMPS ) and 0.5-1 gram of sodium dodecylbenzenesulfonate are added to 200 grams of distilled water, and dissolved for subsequent use;

[0043] 2) Accurately weigh 0.1-0.2 grams of ammonium persulfate, add 25 grams of distilled water, and dissolve for later...

Embodiment 2

[0057] A supramolecular multi-polymer copolymer type clean fracturing fluid is composed of the following components according to the corresponding mass percentages:

[0058] Supramolecular active polymer 0.1%

[0059] Water 99.9%

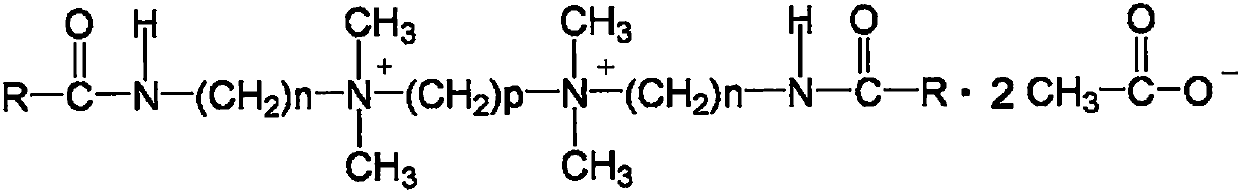

[0060] Wherein, the molecular formula of supramolecular active polymer is as follows:

[0061]

[0062] In the formula, R is a C13-C21 linear or branched alkyl group, n is an integer of 3-6, and p is an integer of 2-4.

[0063] Supramolecular active polymer is obtained by the following steps in the present embodiment:

[0064] 1) Accurately weigh 30-45 grams of acrylamide, 5-10 grams of N-vinylpyrrolidone, 1-2 grams of cetyl acrylate, 2-3 grams of 2-acrylamide-2-methylpropanesulfonic acid (AMPS ) and 0.5-1 gram of sodium dodecylbenzenesulfonate are added to 200 grams of distilled water, and dissolved for subsequent use;

[0065] 2) Accurately weigh 0.1-0.2 grams of ammonium persulfate, add 25 grams of distilled water, and dissolve for later u...

Embodiment 3

[0078] A supramolecular multi-polymer copolymer type clean fracturing fluid is composed of the following components according to the corresponding mass percentages:

[0079] Supramolecular active polymer 0.15%

[0080] Water 98.85%

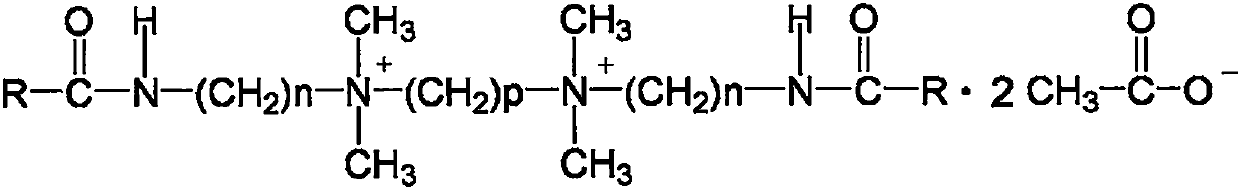

[0081] Wherein, the molecular formula of supramolecular active polymer is as follows:

[0082]

[0083] In the formula, R is a C13-C21 linear or branched alkyl group, n is an integer of 3-6, and p is an integer of 2-4.

[0084] Supramolecular active polymer is obtained by the following steps in the present embodiment:

[0085] 1) Accurately weigh 30-45 grams of acrylamide, 5-10 grams of N-vinylpyrrolidone, 1-2 grams of cetyl acrylate, 2-3 grams of 2-acrylamide-2-methylpropanesulfonic acid (AMPS ) and 0.5-1 gram of sodium dodecylbenzenesulfonate are added to 200 grams of distilled water, and dissolved for subsequent use;

[0086] 2) Accurately weigh 0.1-0.2 grams of ammonium persulfate, add 25 grams of distilled water, and dissolve for later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com