Antistatic, antibacterial, halogen-free and flame-retardant PC/ABS composition and preparation method thereof

A composition and antistatic technology, applied in the field of PC/ABS composite materials, can solve the problems of breeding bacteria, high surface resistance, affecting the appearance of products, etc., and achieve the effect of preventing the breeding of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

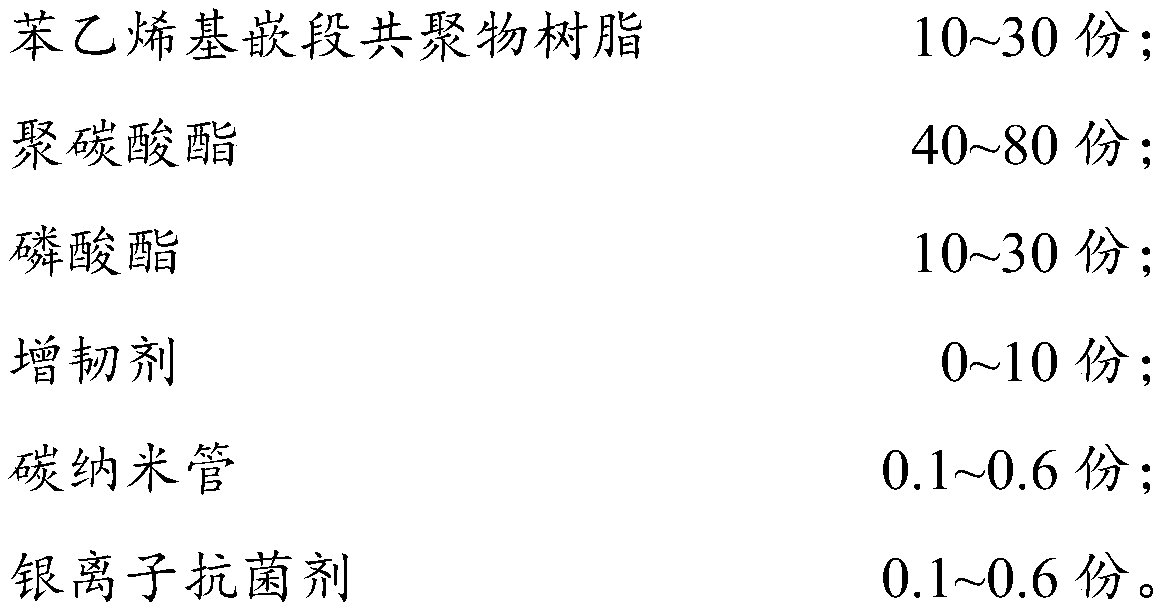

Method used

Image

Examples

Embodiment 1~4

[0021] The raw materials are shown in Table 1.

[0022] ABS is 8391 from Gaoqiao Petrochemical Company; PC is SABIC 2200R, its polycarbonate weight content is 70%, and its melt index is 20.5g / 10min (300℃×1.2kg); BDP is produced by Zhejiang Wansheng with a phosphorus content of 8.5 %,; the toughening agent is DuPont AC@1330, the antistatic agent is single-walled carbon nanotubes produced in Russia; the antioxidant is 168 from Ciba Specialty Chemicals.

[0023] Table 1

[0024] Raw materials (parts by weight) Example 1 Example 2 Example 3 Example 4 ABS8391 10 10 10 10 PC2200R 74 74 74 74 BDP 13 13 13 13 AC@1330 3 3 3 3 antistatic agent 0.1 0.2 0.3 0.4 Silver ion antibacterial agent 0.1 0.2 0.3 0.6 antioxidant 0.2 0.2 0.2 0.2

[0025] Add the above-mentioned raw materials into a high-speed mixer in turn and mix at high speed for 2 minutes, then place the fully mixed mixture in a twin-screw extrud...

Embodiment 5

[0030] Chitosan modified carbon nanotubes are self-made, the specific process is as follows:

[0031] (1) After mixing concentrated sulfuric acid (98%) and concentrated nitric acid (68%) at a volume ratio of 3:1, add single-walled carbon nanotubes, react at 70°C for 3 hours, centrifuge, wash, and dry to obtain carboxylated carbon nanotube.

[0032] (2) dissolving chitosan in the acetic acid solution of pH=5, adding carboxylated carbon nanotubes, the consumption of chitosan is 10% of the quality of carboxylated carbon nanotubes, after stirring for 5h, centrifugal, washing, Dry to obtain chitosan-modified carbon nanotubes.

Embodiment 6

[0034] Chitosan modified carbon nanotubes are self-made, the specific process is as follows:

[0035] (1) adding concentrated nitric acid (68%) to single-walled carbon nanotubes, ultrasonically reacting at 120°C for 3h, centrifuging and washing, then dispersing the carbon nanotubes in water, adding potassium permanganate (concentration is 1g / L) and After reacting with perchloric acid (concentration: 10 wt%) for 10 min, the reaction was quenched with citric acid, centrifuged, washed, and dried to obtain carboxylated carbon nanotubes.

[0036] (2) dissolving chitosan in the acetic acid solution of pH=6, adding carboxylated carbon nanotubes, the consumption of chitosan is 3% of the quality of carboxylated carbon nanotubes, after stirring for 5h, centrifugal, washing, Dry to obtain chitosan-modified carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com