A kind of preparation method of titanium-aluminum alloy material and titanium-aluminum alloy material and its application

A technology of titanium-aluminum alloy and aluminum alloy powder, which is applied in the field of titanium alloy, powder metallurgy, and aluminum alloy. It can solve the problems of difficulty in subsequent runner processing, poor forming processability, and low cost of aluminum alloy, and achieves improved direct diffusion and Solid solution effect, improvement of substrate performance, and effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

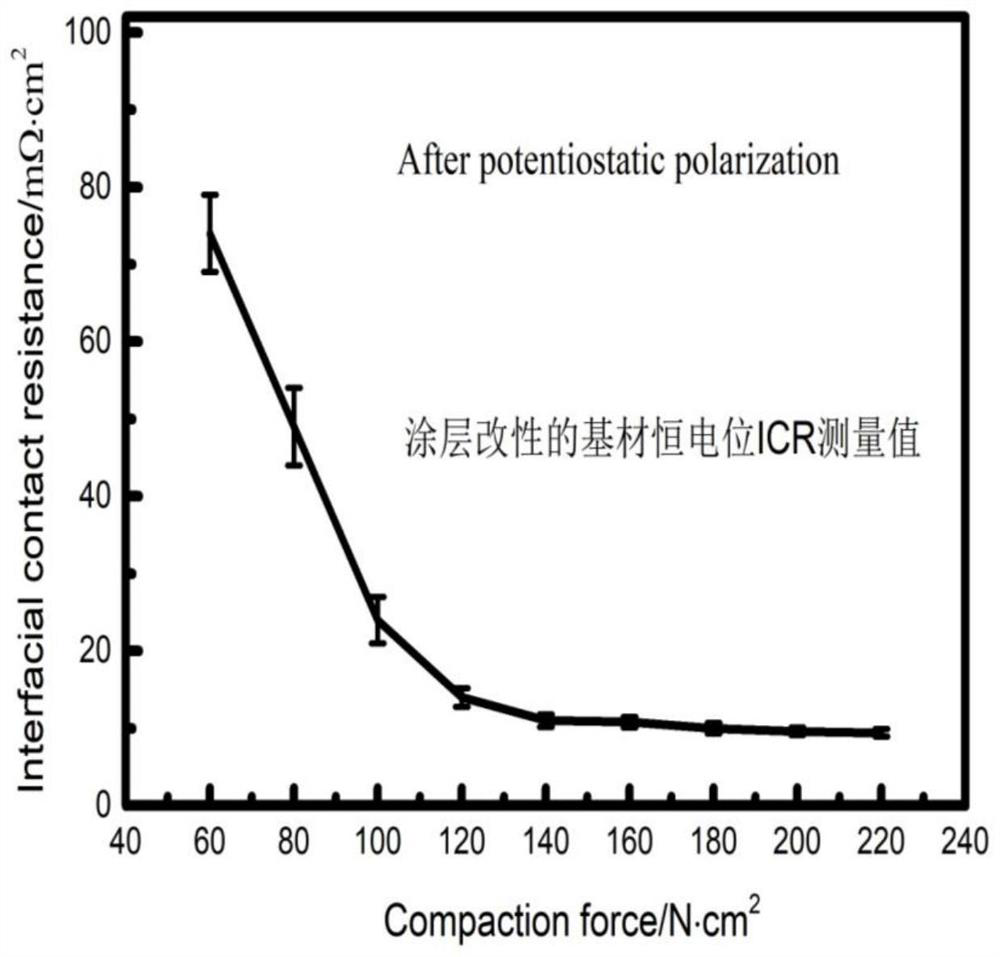

Image

Examples

Embodiment 1

[0044] This embodiment provides a preparation method of a bipolar plate titanium-aluminum alloy material for a proton exchange membrane fuel cell:

[0045] (1) Preparation of materials: Take commercial 6061 aluminum alloy powder and pure titanium powder; take aluminum and titanium powder according to the mass ratio of 7:3 to form aluminum titanium powder Ⅰ; take aluminum and titanium powder according to the mass ratio of 5:5 to form aluminum titanium powder II; take aluminum Titanium powder is composed of aluminum titanium powder III according to the mass ratio of 3:7;

[0046] (2) Ball milling pretreatment: After the commercial 6061 aluminum alloy powder, pure titanium powder, aluminum titanium powder Ⅰ, aluminum titanium powder Ⅱ and aluminum titanium powder Ⅲ are mechanically alloyed in a ball mill, respectively, they are mechanically alloyed in a ball mill respectively. Add polyethylene resin to aluminum-titanium powder Ⅰ, aluminum-titanium powder Ⅱ, aluminum-titanium powd...

Embodiment 2

[0059] This embodiment provides a preparation method of a bipolar plate titanium-aluminum alloy material for a proton exchange membrane fuel cell:

[0060] (1) Preparation of materials: Take commercial 6061 aluminum alloy powder and pure titanium powder; take aluminum and titanium powder according to the mass ratio of 7:3 to form aluminum titanium powder Ⅰ; take aluminum and titanium powder according to the mass ratio of 5:5 to form aluminum titanium powder II; take aluminum Titanium powder is composed of aluminum titanium powder III according to the mass ratio of 3:7;

[0061] (2) Ball milling pretreatment: the commercial 6061 aluminum alloy powder, pure titanium powder, aluminum-titanium powder I, aluminum-titanium powder II and aluminum-titanium powder III are separately mechanically alloyed in a ball mill; Add polyethylene resin to titanium powder Ⅰ, aluminum titanium powder Ⅱ, aluminum titanium powder Ⅲ, 6061 aluminum alloy powder, and pure titanium powder, and mix evenly...

Embodiment 3

[0070] This embodiment provides a preparation method of a bipolar plate titanium-aluminum alloy material for a proton exchange membrane fuel cell:

[0071] (1) Preparation of materials: Take commercial 6061 aluminum alloy powder and pure titanium powder; take aluminum and titanium powder according to the mass ratio of 7:3 to form aluminum titanium powder Ⅰ; take aluminum and titanium powder according to the mass ratio of 5:5 to form aluminum titanium powder II; take aluminum Titanium powder is composed of aluminum titanium powder III according to the mass ratio of 3:7;

[0072] (2) Ball milling pretreatment: the commercial 6061 aluminum alloy powder, pure titanium powder, aluminum-titanium powder I, aluminum-titanium powder II and aluminum-titanium powder III are separately mechanically alloyed in a ball mill; Add polyethylene resin to titanium powder Ⅰ, aluminum titanium powder Ⅱ, aluminum titanium powder Ⅲ, 6061 aluminum alloy powder, and pure titanium powder, and mix evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com