Ti6Al4V alloy powder, preparation method of Ti6Al4V alloy powder and 3D printed product

A 3D printing and alloy powder technology, which is applied in the direction of additive manufacturing, energy efficiency improvement, additive processing, etc., can solve the problems of restricting the popularization and application of titanium alloy selective laser melting 3D printing molding, high price, complex process, etc., and achieve mechanical properties Outstanding, low cost, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of Ti 6 Al 4 V alloy powder, its preparation method comprises the following steps:

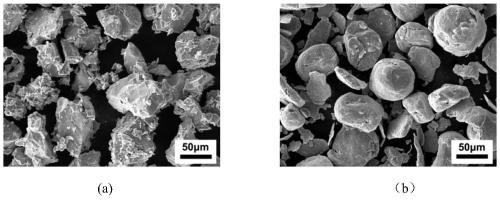

[0028] S1. Put the hydrogenated dehydrogenated titanium powder and agate balls into the ball milling equipment according to the ratio of ball to material ratio of 5:1, and add ethanol to cover the hydrogenated dehydrogenated titanium powder and agate balls, and then pass in argon to discharge the air , carry out ball milling modification treatment, ball milling process ball mill rotating speed is 150rpm, ball milling modification time is 6h; After finishing ball milling modification treatment, stand for 2h, make spherical titanium powder;

[0029] S2. Put the spherical titanium powder, aluminum powder and vanadium powder prepared in step S1 in a three-dimensional powder mixer, wherein the aluminum powder accounts for 6wt.% of the total powder after mixing, and the vanadium powder accounts for 4wt of the total powder after mixing. .%; mixed for 1h to obtain Ti 6 Al 4 V alloy p...

Embodiment 2

[0032] A kind of Ti 6 Al 4 V alloy powder, its preparation method comprises the following steps:

[0033] S1. Put the hydrogenated dehydrogenated titanium powder and agate balls into the ball milling equipment according to the ratio of ball to material ratio of 3:1, and add ethanol to cover the hydrogenated dehydrogenated titanium powder and agate balls, and then pass in argon to discharge the air , carry out ball milling modification treatment, ball milling process ball mill rotating speed is 200rpm, ball milling modification time is 5h; after finishing ball milling modification treatment, stand for 2h, make spherical titanium powder;

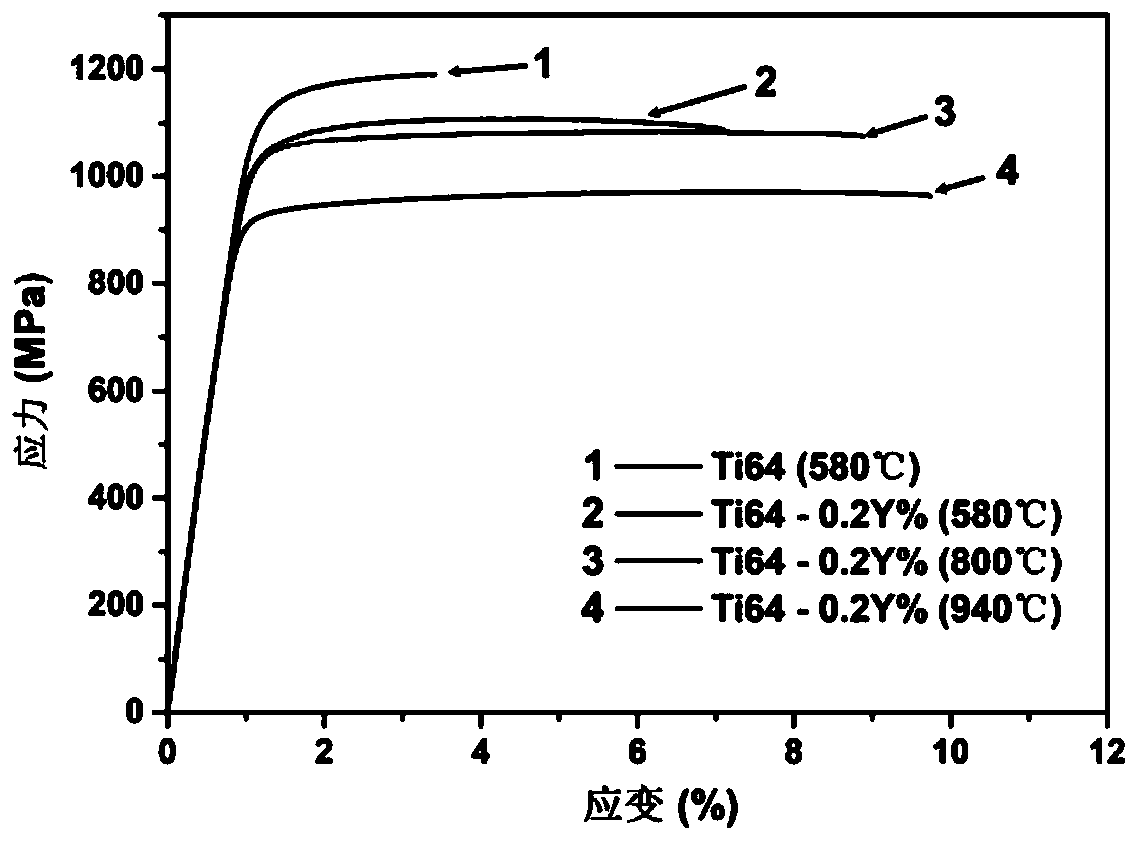

[0034] S2. Put the spherical titanium powder, aluminum powder, vanadium powder and yttrium powder prepared in step S1 in a three-dimensional powder mixer, wherein the aluminum powder accounts for 6wt.% of the total powder after mixing, and the vanadium powder accounts for 6wt.% of the total powder after mixing. 4wt.% of the powder, and the y...

Embodiment 3

[0037] A kind of Ti 6 Al 4 V alloy powder, its preparation method comprises the following steps:

[0038] S1. Put the hydrogenated dehydrogenated titanium powder and agate balls into the ball milling equipment according to the ratio of ball to material ratio of 3:1, and add ethanol to cover the hydrogenated dehydrogenated titanium powder and agate balls, and then pass in argon to discharge the air , carrying out ball milling modification treatment, ball milling process ball mill speed is 200rpm, ball milling modification time is 4h; After ball milling modification treatment is completed, stand for 2h to obtain spherical titanium powder;

[0039] S2. Put the spherical titanium powder, aluminum powder, vanadium powder and yttrium powder prepared in step S1 in a three-dimensional powder mixer, wherein the aluminum powder accounts for 6wt.% of the total powder after mixing, and the vanadium powder accounts for 6wt.% of the total powder after mixing. 4wt.% of the powder, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com