Antibacterial and anti-mosquito XPE foam material and preparation method thereof

A foaming material and anti-mosquito technology, which is applied in the field of polymer foam materials, can solve problems such as affecting skin health, affecting user experience, and easy to have mosquitoes crawling, and achieves the effect of good mosquito repellent, improved comfort, and elegant taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

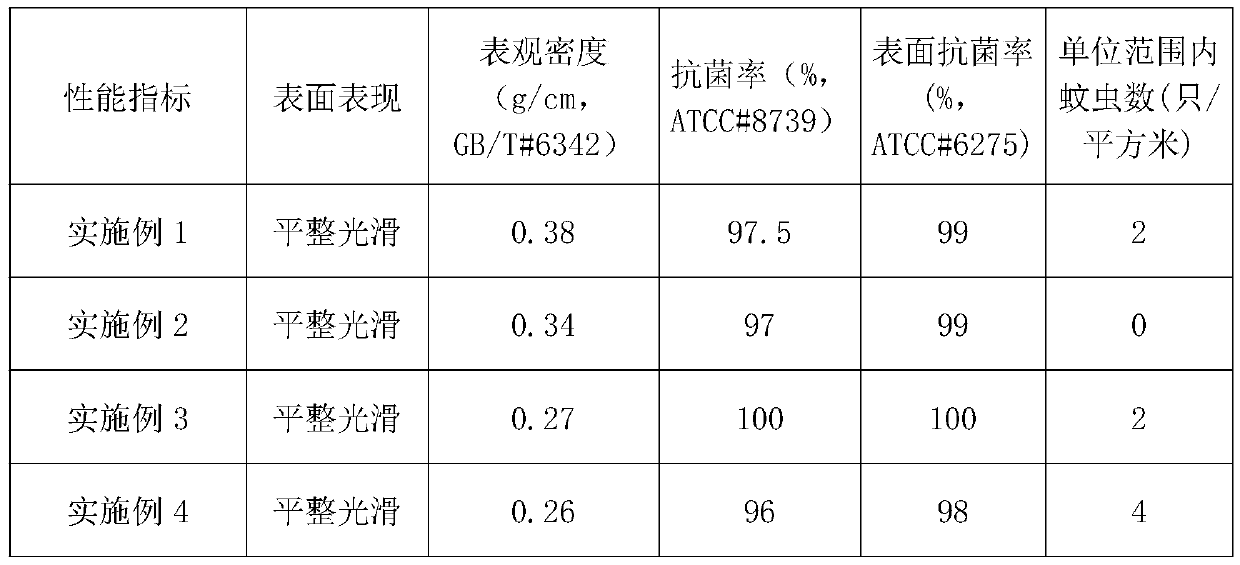

Examples

Embodiment 1

[0039] An antibacterial and anti-mosquito XPE foaming material, which is prepared from the following components in parts by weight: PE resin, foaming agent masterbatch, crosslinking agent masterbatch, mosquito repellent masterbatch, antibacterial masterbatch, processing aid, color masterbatch;

[0040] Wherein, by weight,

[0041] The foaming agent masterbatch is made by mixing AC foaming agent and polyethylene (PE) in a ratio of 1:2, banburying and granulating;

[0042] The cross-linking agent master batch is prepared by mixing DCP cross-linking agent and polyethylene (PE) in a ratio of 1:20, banburying and granulating;

[0043] The mosquito repellent masterbatch is prepared by mixing mosquito repellent Chinese herbal medicine powder and polyethylene (PE) at a ratio of 1:4, followed by banburying and granulation.

[0044] The mosquito-repelling Chinese herbal medicine powder is one or a mixture of perrin, atractylodes, ageratum, clove, mugwort, angelica, perilla, peppermint...

Embodiment 2

[0053] An antibacterial and anti-mosquito XPE foaming material, which is prepared from the following components in parts by weight: PE resin, foaming agent masterbatch, crosslinking agent masterbatch, mosquito repellent masterbatch, antibacterial masterbatch, processing aid, color masterbatch;

[0054] Wherein, by weight,

[0055] The foaming agent masterbatch is made by mixing AC foaming agent and polyethylene (PE) in a ratio of 1:2, banburying and granulating;

[0056] The cross-linking agent master batch is prepared by mixing DCP cross-linking agent and polyethylene (PE) in a ratio of 1:20, banburying and granulating;

[0057] The mosquito repellent masterbatch is prepared by mixing mosquito repellent Chinese herbal medicine powder and polyethylene (PE) at a ratio of 1:4, followed by banburying and granulation.

[0058] The mosquito-repelling Chinese herbal medicine powder is one or a mixture of perrin, atractylodes, ageratum, clove, mugwort, angelica, perilla, peppermint, ...

Embodiment 3

[0067] An antibacterial and anti-mosquito XPE foaming material, which is prepared from the following components in parts by weight: PE resin, foaming agent masterbatch, crosslinking agent masterbatch, mosquito repellent masterbatch, antibacterial masterbatch, processing aid, color masterbatch;

[0068] Wherein, by weight,

[0069] The foaming agent masterbatch is made by mixing AC foaming agent and polyethylene (PE) in a ratio of 1:2, banburying and granulating;

[0070] The cross-linking agent master batch is prepared by mixing DCP cross-linking agent and polyethylene (PE) in a ratio of 1:20, banburying and granulating;

[0071] The mosquito repellent masterbatch is prepared by mixing mosquito repellent Chinese herbal medicine powder and polyethylene (PE) at a ratio of 1:4, followed by banburying and granulation.

[0072] The mosquito-repelling Chinese herbal medicine powder is one or a mixture of perrin, atractylodes, ageratum, clove, mugwort, angelica, perilla, peppermint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com