Environment-friendly pre-vulcanization reforming pre-hydrogenation catalyst, preparation method and application thereof

A green and environmentally friendly catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as complex processes and insufficient energy utilization, and achieve high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

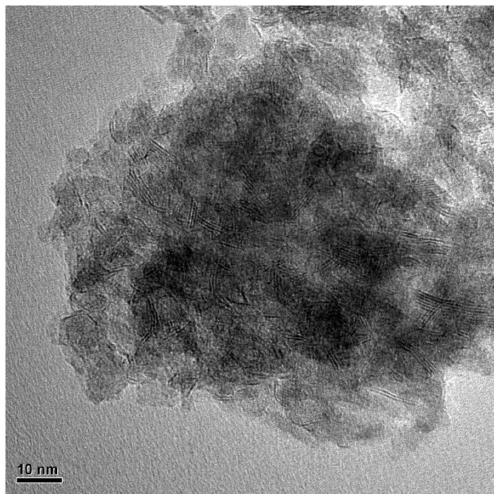

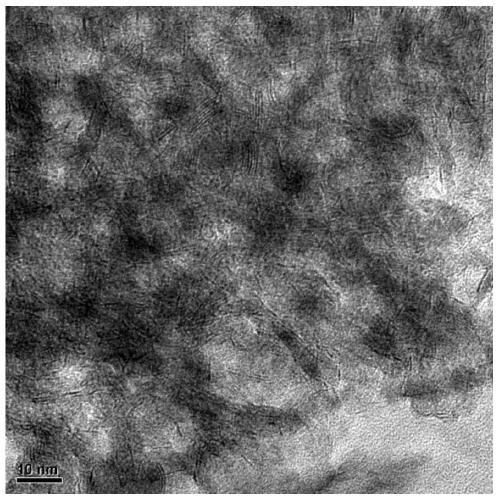

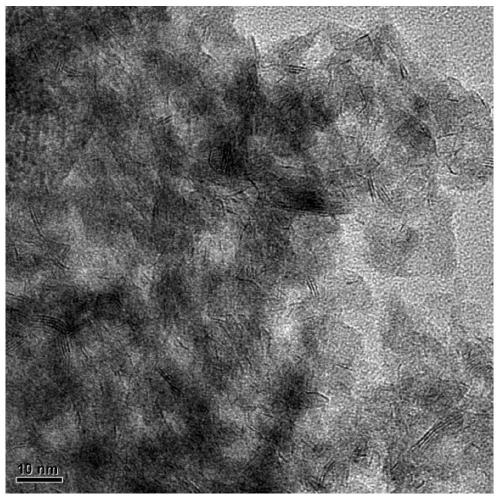

Image

Examples

preparation example Construction

[0057] The invention discloses a preparation method of a green and environment-friendly presulfidation reforming prehydrogenation catalyst. The preparation method comprises the following steps:

[0058] Step 1, the catalyst carrier is impregnated with active components, dried at 110-170°C, and calcined at 480-520°C;

[0059] Step 2, cooling the catalyst calcined in step 1 to 250-280°C;

[0060] Step 3, heat up the pre-vulcanizing agent to 250-280°C, impregnate and mix with the catalyst cooled to 250-280°C in step 2, keep the temperature constant for 1-2 hours, then cool down to 40-60°C, and then spray the accelerator pouring, keep the temperature down to room temperature after 1-2 hours, and obtain a pre-sulfided reforming pre-hydrogenation catalyst.

[0061] Among them, firstly, the catalyst preparation process is not particularly limited in the present invention, and methods known to those skilled in the art are all available. The catalyst carrier can be one or more of the...

Embodiment 1

[0084]A reforming pre-hydrogenation catalyst of molybdenum-nickel active metal components, the content of molybdenum trioxide on 100g of the catalyst is 17g, the content of nickel oxide is 3g, the calcination temperature of the catalyst is 480°C, and the temperature is lowered to 250°C at 15°C / h pre-vulcanized treatment. The pre-vulcanizing agent is prepared by mixing 15g FCC gasoline, 4g castor oil, 4g soybean oil, 1g corn oil, 6g cyclohexane, 0.03g citric acid, 3g elemental sulfur, and 5g ethanethiol. Stir evenly and heat up at 10°C / h To 250°C, impregnate the catalyst at a constant temperature of 250°C in the presulfiding agent, and keep the temperature constant for 1.0h, then lower it to 50°C at 10°C / h, and spray 200μg / g (the proportion of the accelerator to the total amount of the catalyst) The dithiol benzothiazole solution was sprayed for 5 minutes, kept at a constant temperature for 1.0 h, and then lowered to room temperature at 15°C / h to obtain sample-1.

Embodiment 2

[0086] A reforming prehydrogenation catalyst of cobalt-molybdenum-nickel active metal component, molybdenum trioxide content is 13g on 100g catalyst, nickel oxide content is 3g, cobalt oxide 2g, the roasting temperature of catalyst is 500 ℃, with 20 ℃ / h Lower the temperature to 260°C for pre-vulcanization treatment. The presulfurizing agent is 14g FCC gasoline, 5g castor oil, 5g soybean oil, 2g safflower oil, 3g corn oil, 8g n-heptane, 0.005g citric acid, 1g elemental sulfur, 2g ethanethiol, 3g CS 2 Carry out mixing and preparation, after stirring evenly, raise the temperature to 260°C at 12°C / h, impregnate the catalyst at a constant temperature of 260°C in the pre-vulcanizing agent, and keep the temperature constant for 1.5 hours, then lower it to 40°C at 15°C / h, spray 1000μg / h g (the ratio of the accelerator to the total amount of the catalyst) of dithiol-benzothiazole solution, the spray time was 15 minutes, the temperature was kept constant for 2.0 hours, and then cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com