Hydrogenation catalyst with large specific surface and low acid amount, and application thereof

A catalyst and specific surface technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of alumina carrier specific surface reduction, alumina crystal phase limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

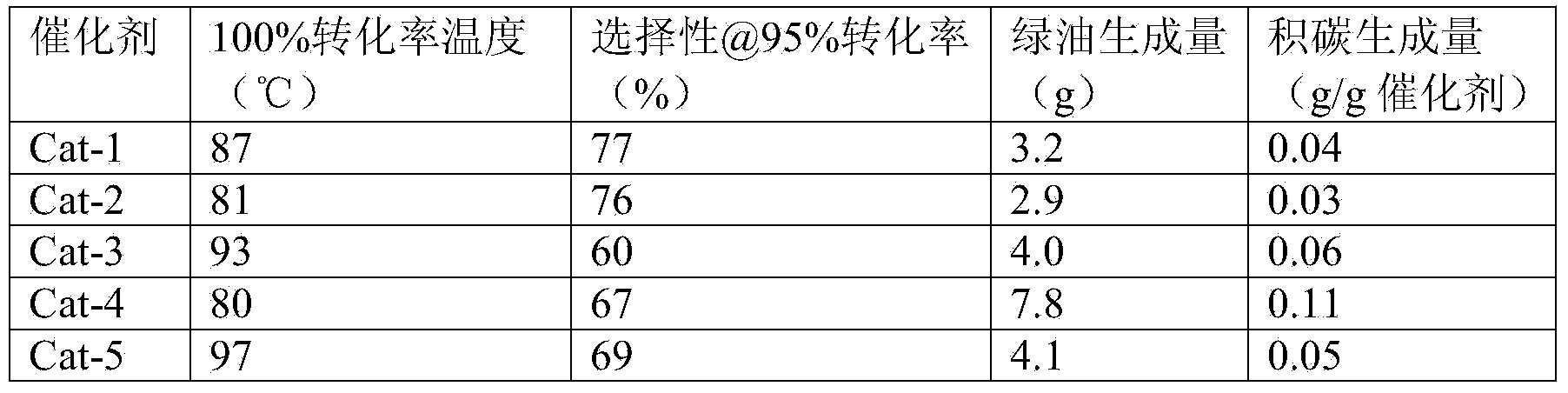

Embodiment 1

[0046] Get 300g of pseudo-boehmite (produced by China Aluminum Shandong Branch) produced by carbonization, add 240g of aqueous solution (wherein containing 2wt% of phosphoric acid, 1wt% of nitric acid, 1.5wt% of lanthanum nitrate), 3.0g of Tianqing powder, and extrude Shaped into a clover, the size is 2.0~3.0mm. After the obtained precursor was calcined at 900°C for 3 hours, the specific surface of alumina obtained was 200m 2 / g. Put the above-mentioned alumina into a fixed-bed reactor, raise the temperature to 100°C, and then pass in nitrogen containing hexamethyldisilazane vapor for 3 hours, then pass in air and heat up to 450°C for 2 hours to obtain a Modified alumina.

[0047] Get above-mentioned aluminum oxide 100ml, be respectively 0.02%, 0.8% and 2.0% according to the mass percent of Pd, Ag and K, the balance is Al 2 o 3 The ratio of palladium nitrate, silver nitrate and potassium nitrate was prepared by equal-volume impregnation method, and Cat-1 was obtained after...

Embodiment 2

[0049] Get 150g of pseudo-boehmite (produced by Sinopec) produced by sulfuric acid method, add 150g dry rubber powder (produced by China Aluminum Shandong Branch) and mix evenly, add 260g of aqueous solution (wherein containing nitric acid 3wt%, zinc nitrate .5wt% ), Tianqing powder 5.0g, shaped into a toothed spherical shape with a size of 1.0-3.0mm. Calcining the obtained precursor at 1000°C for 3 hours resulted in a specific surface of alumina of 165m 2 / g.

[0050] Put 100ml of the above-mentioned alumina into a glass reactor, add 500ml of p-xylene solution containing 5wt% methyltriethoxysilane, start stirring and gradually raise the temperature to 150°C and keep it at a constant temperature for 3 hours, then the obtained carrier Filter and dry, and roast and decompose at 600°C for 3 hours to obtain modified alumina.

[0051] Get 50 grams of the above-mentioned modified alumina, according to the mass percentages of Pd, La and Ca, they are respectively 0.02%, 0.08% and 0....

Embodiment 3

[0053] Get 100g of commercial alumina spherical carrier (produced by Aluminum Corporation of China Shandong Branch, specific surface area 205m 2 / g), roasting and decomposing at 900°C for 3 hours, the specific surface area becomes 158cm 2 / g. It is subjected to silanization treatment, and the treatment conditions are consistent with Example 1.

[0054] The above-mentioned modified alumina is used for catalyst manufacture, and the mass percentages of Pd, Ag and Bi are 0.05%, 0.3% and 1.0% respectively, and the balance is prepared by configuring palladium nitrate, silver nitrate and bismuth nitrate according to the ratio of the carrier The aqueous solution is prepared by spraying, dried and calcined at 480°C to obtain a catalyst Cat-3. NH on the catalyst 3 -TPD analysis, the total acid content is 0.130 mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com