Edible bacillus coagulans powder and preparation process thereof

A technology of Bacillus coagulans and a preparation process, which is applied to the field of edible Bacillus coagulans powder and its preparation process, can solve the problems of not being a food additive, etc., and achieve a good bacteriostatic effect, improve the frequency of diarrhea, and improve the effects of constipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

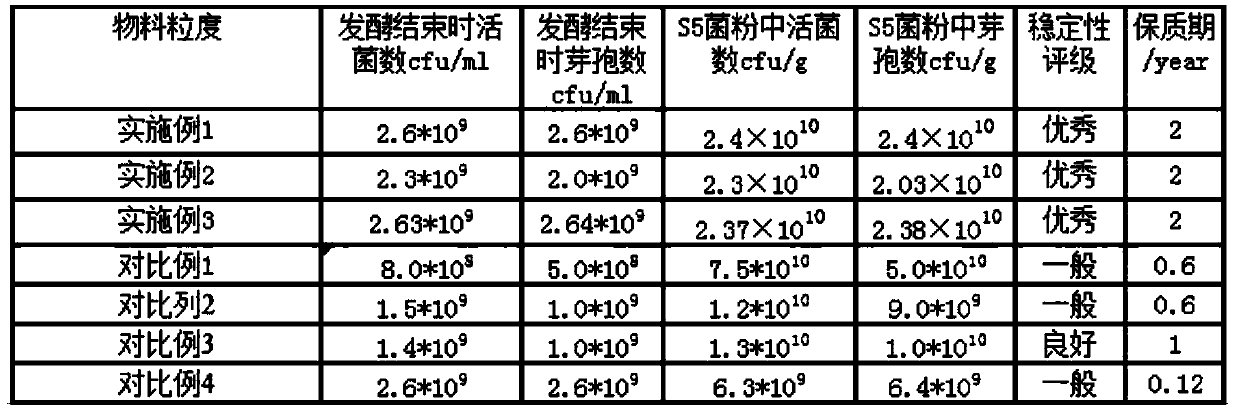

Examples

preparation example Construction

[0034] A preparation process for edible Bacillus coagulans bacteria powder, said method specifically comprising the following preparation steps:

[0035] S1, raw material equipment: weigh the raw material of Bacillus coagulans bacteria powder according to the above parts by weight;

[0036] S2. Superfine pulverization: the raw materials of the Bacillus coagulans powder include oat bran, bee pollen, silkworm chrysalis, and wheat germ are superfine pulverized, so that the particle size of the raw materials is less than 300 mesh;

[0037] S3, mixing raw materials, inoculating: the ultrafine raw material obtained in S2 is mixed with the carbon source according to the above-mentioned mass ratio, the food additives of the above-mentioned mass ratio can be added, and the water of a certain weight fraction is taken and stirred evenly; the mass concentration of oat bran is 0.5-2%; After homogenizing the evenly distributed slurry, adjust the pH value to 6.5-7.0, and inoculate Bacillus c...

Embodiment 1

[0047] An edible Bacillus coagulans powder, which is prepared by superfine pulverization, fermentation and drying, and the raw materials of the Bacillus coagulans powder include the following components by weight: 1 part of oat bran, honey 1 part pollen, 1 part silkworm chrysalis, 1 part wheat germ, 1 part carbon source. The carbon source includes maltodextrin and inulin with a mass ratio of 2:1. The raw material of the Bacillus coagulans powder also includes food additives, the mass ratio of which is 8:5:3:0.5; the food additive is 15% of the total raw material mass of the Bacillus coagulans powder.

[0048] A preparation process for edible Bacillus coagulans bacteria powder, said method specifically comprising the following preparation steps:

[0049] S1, raw material equipment: weigh the raw material of Bacillus coagulans bacteria powder according to the above parts by weight;

[0050] S2. Superfine pulverization: the raw materials of the Bacillus coagulans powder include...

Embodiment 2

[0057] An edible Bacillus coagulans powder, which is obtained by superfine pulverization, fermentation and drying, and the raw materials of the Bacillus coagulans powder include the following components in parts by weight: 0.5 part of oat bran, honey 0.25 parts of pollen, 0.5 parts of silkworm chrysalis, 0.5 parts of wheat germ, and 0.5 parts of carbon source.

[0058] The carbon source includes maltodextrin and inulin with a mass ratio of 1:1. The raw material of the Bacillus coagulans powder also includes food additives, the mass ratio of which is 3:2:0.5:0.1; the food additive is 1% of the total raw material mass of the Bacillus coagulans powder.

[0059] A preparation process for edible Bacillus coagulans bacteria powder, said method specifically comprising the following preparation steps:

[0060] S1, raw material equipment: weigh the raw material of Bacillus coagulans bacteria powder according to the above parts by weight;

[0061] S2. Superfine pulverization: the raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com