A kind of substrate hybrid film multilayer wiring manufacturing method

A multi-layer wiring and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problem of inability to increase the number of film wiring layers, difficulty in assembling soft substrates, and poor interconnection reliability To achieve the effect of electromagnetic shielding performance, reduce signal transmission loss, and reduce device junction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A method for fabricating a substrate hybrid thin-film multilayer wiring proposed by the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. The advantages and features of the present invention will become apparent from the following description and claims.

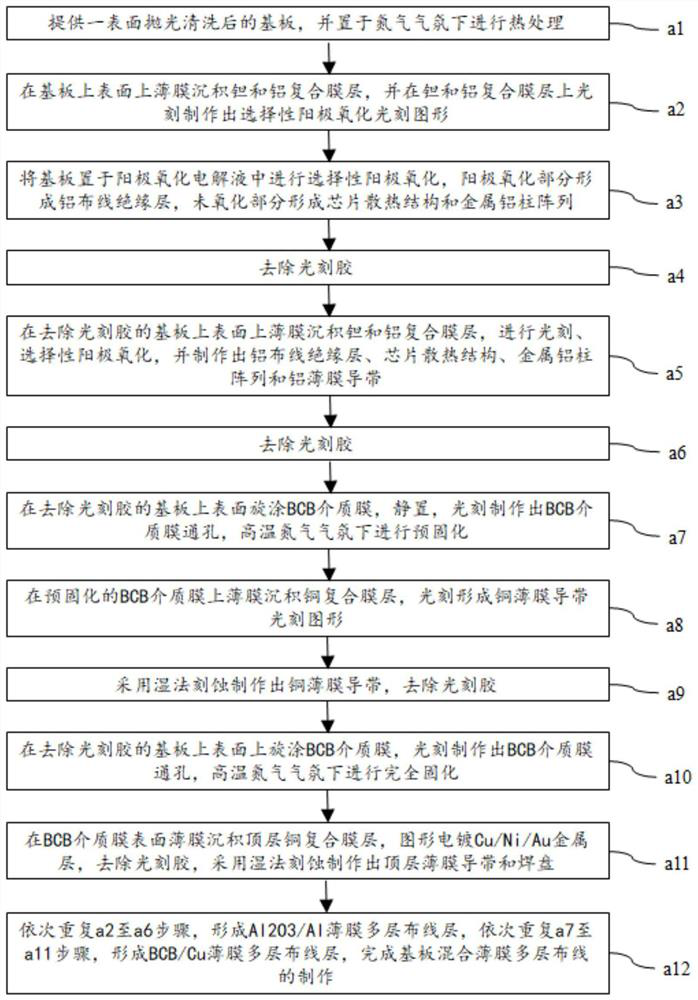

[0040] see figure 1 , in one embodiment, a method for fabricating a substrate hybrid thin-film multilayer wiring, comprising the following steps:

[0041] a1: Provide a substrate after surface polishing and cleaning, and place it in a nitrogen atmosphere for heat treatment;

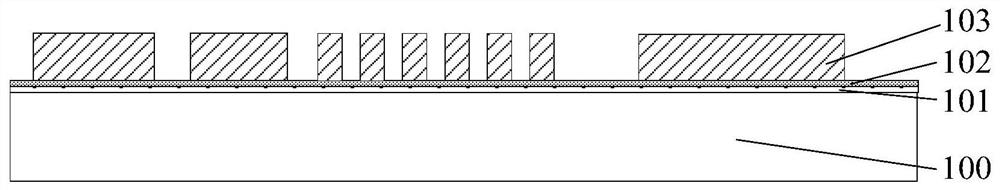

[0042] a2: Thin film deposition of a tantalum and aluminum composite film on the upper surface of the substrate, and photolithography to produce a selective anodic oxidation lithography pattern on the tantalum and aluminum composite film;

[0043] a3: The substrate is placed in an anodizing electrolyte for selective anodization, the anodized part forms an insulating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com