Preparation method of high-light-transmittance thermal-insulation impact-resistant composite material

A composite material, high light transmittance technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of cumbersome and difficult wrapping, increased material thickness and density, and insufficient sealing, and achieves efficient radiation diffusion isolation. The effect of thermal insulation, improving light transmission, preventing convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

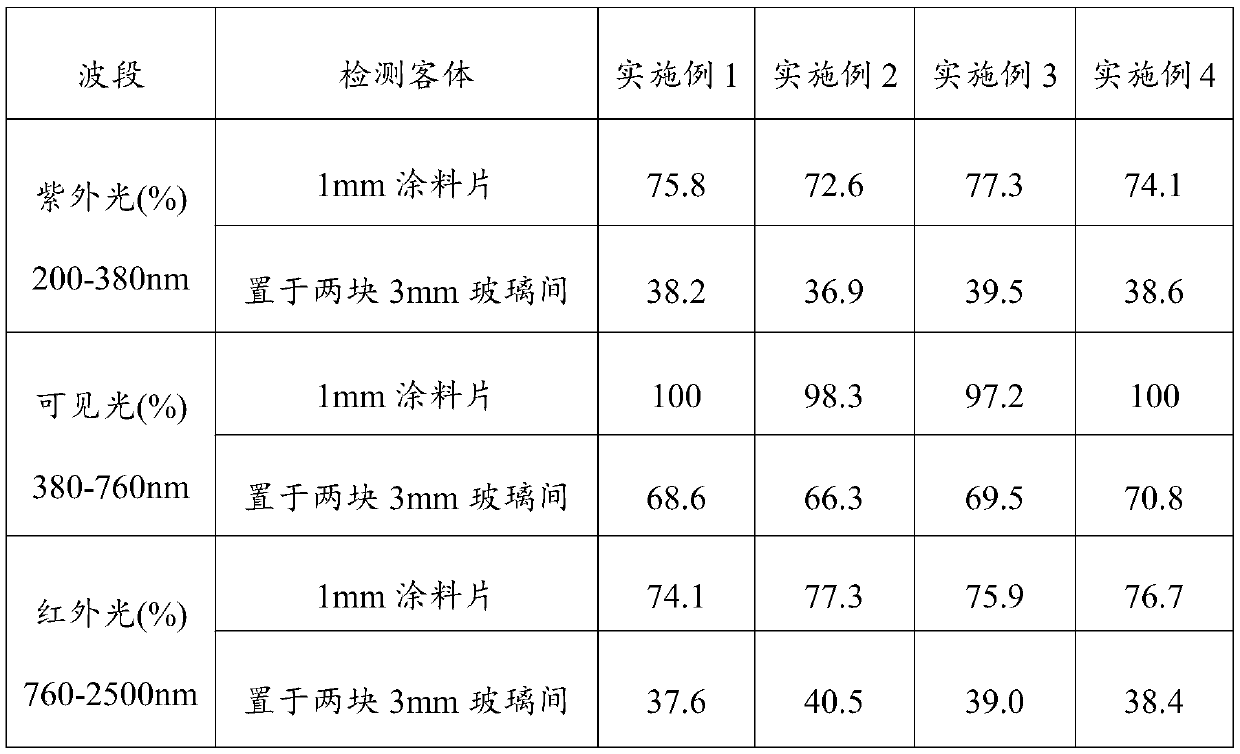

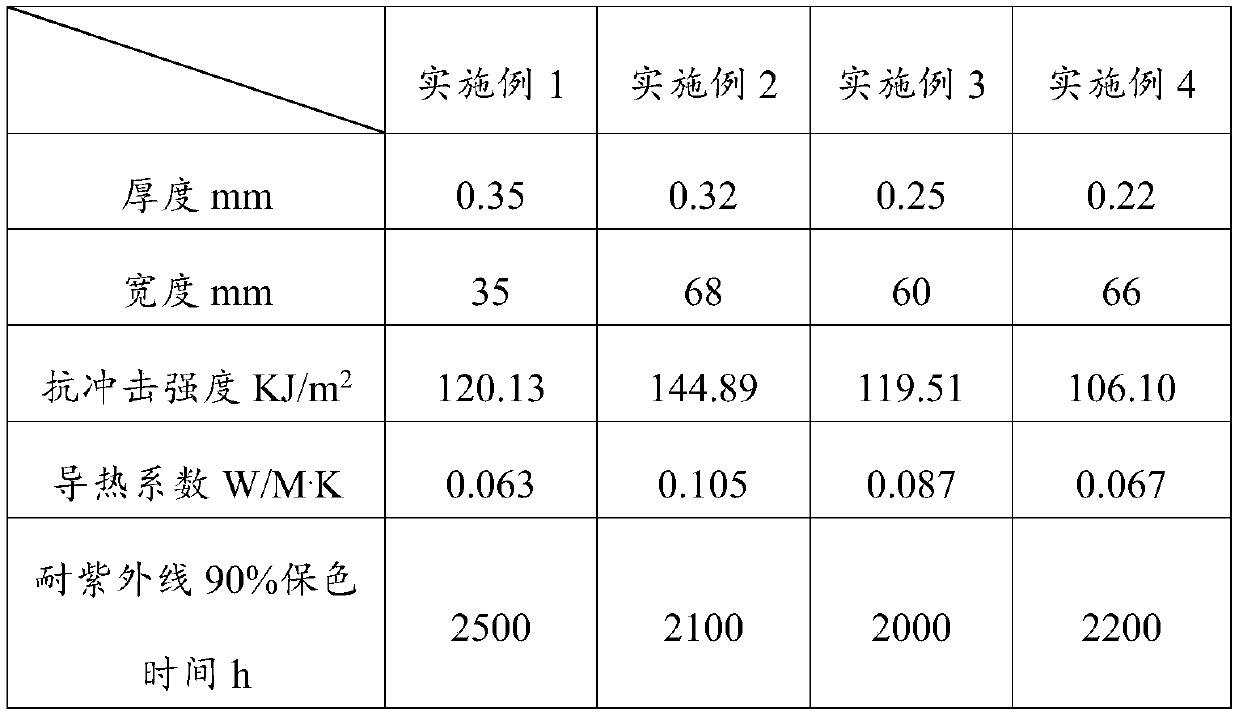

Examples

Embodiment 1

[0034] A method for preparing a heat-insulating and impact-resistant composite material with high light transmittance, comprising the following steps:

[0035] S1. Functional nano-hollow thermal insulation inorganic material selection: select silica airgel as the hollow thermal insulation inorganic material.

[0036] S2. To repair and aminate the surface of nano thermal insulation functional materials, the specific steps are as follows:

[0037] 1. Add 50g of silica airgel into a 10L airtight fluidized fluidized furnace, and slowly raise the temperature of the fluidized fluidized furnace to 60°C.

[0038] 2. Pump 250g of high-purity liquid ammonia into the fluidized furnace through a high-pressure tetrafluoroethylene-lined air pump. The liquid ammonia enters the fluidized furnace and immediately gasifies. Start the fluidized furnace airflow crushing device to slowly raise the temperature of the fluidized furnace to 120 ° C. The heating rate is controlled at 3°C / min,

[0039]...

Embodiment 2

[0063] A method for preparing a heat-insulating and impact-resistant composite material with high light transmittance, comprising the following steps:

[0064] S1. Functional nano-hollow thermal insulation inorganic material selection: select nano-graphite airgel as the hollow thermal insulation inorganic material.

[0065] S2. To repair and aminate the surface of nano thermal insulation functional materials, the specific steps are as follows:

[0066] 1. Add 50g of nano-graphite airgel into a 10L airtight fluidized fluidized furnace, and slowly raise the temperature of the fluidized fluidized furnace to 55°C.

[0067] 2. Pump 250g of high-purity liquid ammonia into the fluidized furnace through a high-pressure tetrafluoroethylene-lined air pump. The liquid ammonia enters the fluidized furnace and immediately gasifies. Start the fluidized furnace airflow crushing device to slowly raise the temperature of the fluidized furnace to 110 ° C. The heating rate is controlled at 1°C / ...

Embodiment 3

[0092] A method for preparing a heat-insulating and impact-resistant composite material with high light transmittance, comprising the following steps:

[0093] S1. Functional nano-hollow thermal insulation inorganic material selection: Hollow glass microspheres are selected as the hollow thermal insulation inorganic material.

[0094] S2. To repair and aminate the surface of nano thermal insulation functional materials, the specific steps are as follows:

[0095] 1. Add 50g of hollow glass microspheres into a 10L airtight fluidized fluidized furnace, and slowly raise the temperature of the fluidized fluidized furnace to 60°C.

[0096] 2. Pump 250g of high-purity liquid ammonia into the fluidized furnace through a high-pressure tetrafluoroethylene-lined air pump. The liquid ammonia enters the fluidized furnace and immediately gasifies. Start the fluidized furnace airflow crushing device to slowly raise the temperature of the fluidized furnace to 130 ° C. The heating rate is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com