Antibacterial PE shrink film and processing method thereof

A technology of shrink film and compound antibacterial agent, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of decreased antibacterial performance, reduced applicability, weak antibacterial performance, etc., and achieve excellent mechanical properties , The level of mold growth does not decrease significantly, and the effect of antibacterial time is long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] Graphene oxide loaded silver ion antibacterial agent among the present invention adopts following preparation method to prepare:

[0037] Weigh 0.5g of graphene oxide powder and disperse it in 1L of deionized water, and obtain a graphene oxide dispersion liquid by fully exfoliating it through ultrasound; then add 0.5L N-methylpyrrolidone to it, and fully mix it through ultrasound to obtain a graphene oxide aqueous solution;

[0038] Dissolve an appropriate amount of silver nitrate in deionized water, then add sodium sulfite to it, control the molar ratio of sodium sulfite to silver nitrate to 1.2:1, react at 10°C for 2 hours, control the amount of silver nitrate and sodium sulfite added, and finally get 1g of silver complexes;

[0039] The above graphene oxide aqueous solution was mixed with the above silver complex, mixed at 35°C for 1 hour, the precipitate was filtered out, washed three times with deionized water, and dried to obtain a graphene oxide-loaded silver ion...

Embodiment 1

[0041] An antibacterial PE shrink film, which is a monolayer film, is processed through the following steps:

[0042] (1) Prepare LDPE, HDPE, mLLDPE, PE wax and composite antibacterial agent according to the dosage in Table 1, stir in the mixer for 15min, and send it into the extruder corresponding to the multi-layer co-extrusion film blowing unit to extrude; , the barrel temperature of the control extruder is: 25°C in zone I, 115°C in zone II, 150°C in zone III, 155°C in zone IV, 155°C in zone V, 155°C in zone VI, and 160°C at the head; the traction speed is 25m / min;

[0043] (2) At 170°C, the inflation ratio is controlled to be 2.0, and it is produced by one-time inflation of a multi-layer co-extrusion blown film machine, and then the finished antibacterial PE shrink film is obtained by cutting and winding;

[0044] Among them, the compound antibacterial agent is processed through the following operations: mix the bacteria and algae clear, inorganic antibacterial agent, ca...

Embodiment 2-5

[0046] The antibacterial PE shrink film of embodiment 2-5 and embodiment 1, processing technology is the same, the difference is that the kind and the dosage of each raw material are different, as shown in table 1 specifically.

[0047] Each raw material dosage (unit: g) of antibacterial PE shrink film in the embodiment 1-5 of table 1

[0048] Example 1 Example 2 Example 3 Example 4 Example 5 LDPE 400 500 600 450 550 HDPE 200 300 150 180 250 mLLDPE 200 300 150 180 250 PE wax 80 125 150 100 130 Compound antibacterial agent 40 10 100 30 80

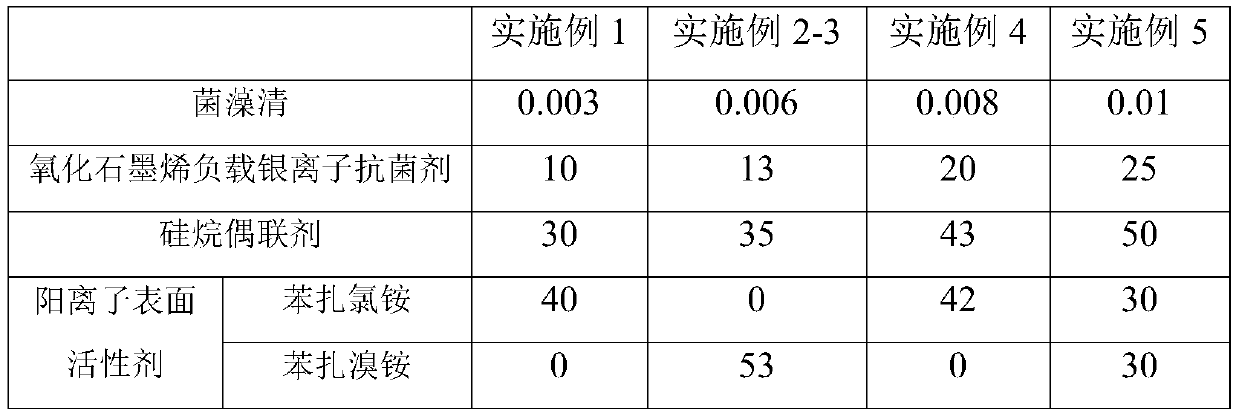

[0049] Each raw material composition and dosage (unit: g) of compound antibacterial agent in table 2 embodiment 1-5

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com