Method for inhibiting coating shrinkage rate of water-based filler, and pipe tool thereof

A shrinkage, water-based technology, applied in the field of fillers, can solve problems such as low efficiency and poor effect, and achieve the effect of solving shrinkage rate, reducing shrinkage rate, and ingenious method design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

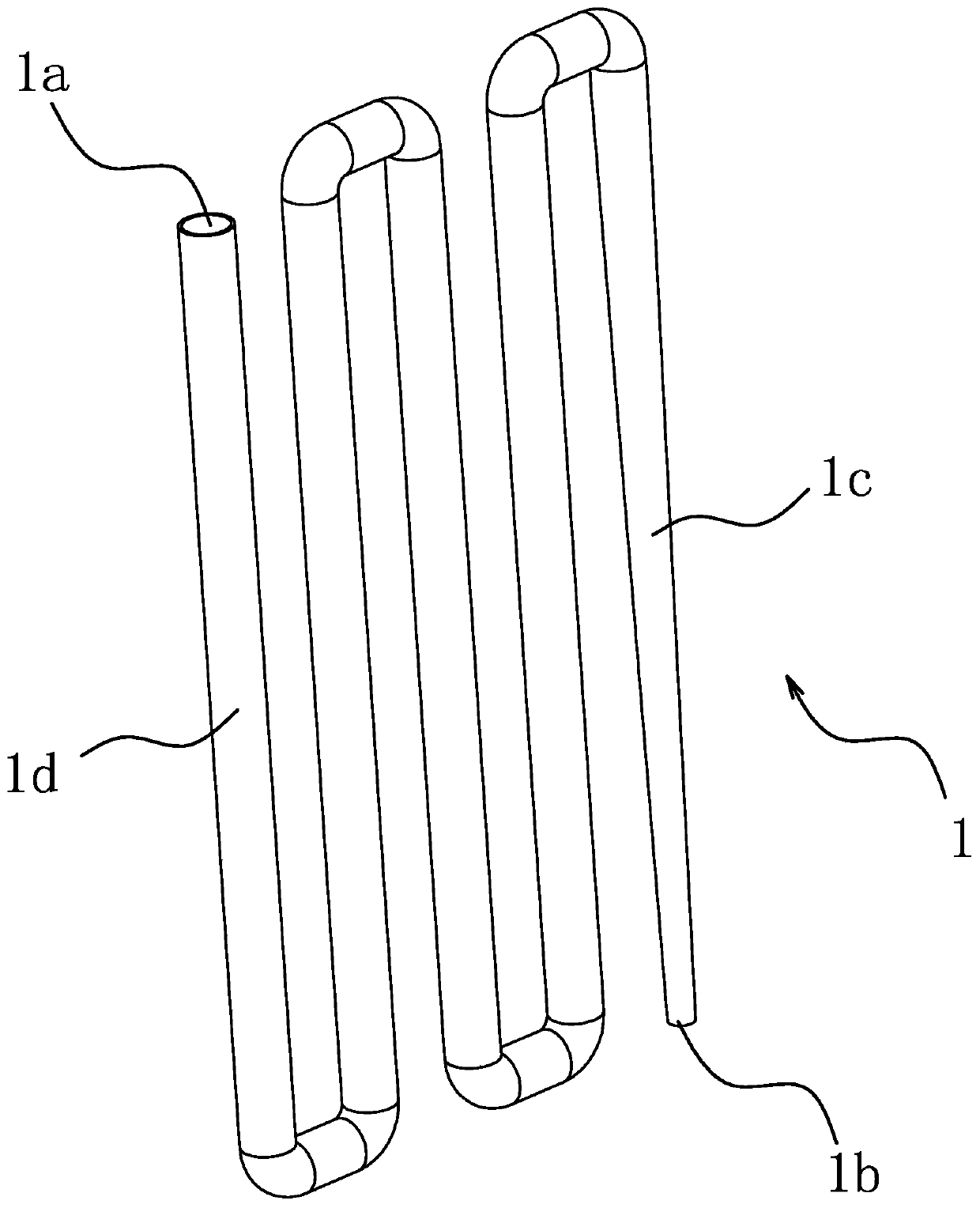

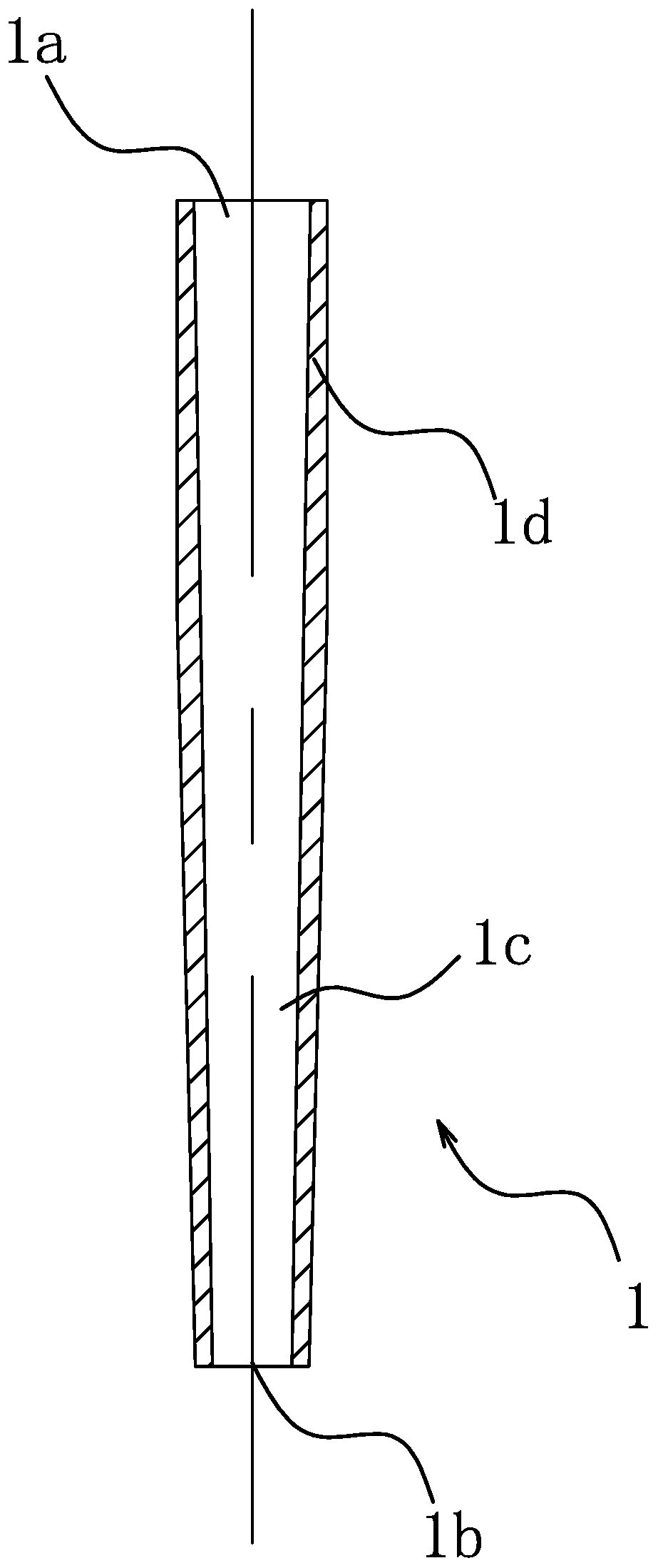

[0050] Such as figure 1 and Figure 4 As shown, the method for suppressing the coating shrinkage of the water-based filler includes a sudden heat output, and the water-based filler comprising an amine curing agent, a water-based epoxy resin and a pigment is passed through the necking-shaped pipe 1 at a temperature of 85°; gradually cooled output, The water-based filler that has been output by sudden heating is passed through multiple necked pipes 1 in a staged cooling manner in the range of 50°-5°, that is, in the gradual cooling output, the temperature environment for the first time is 50°, and the final output of the filler is The ambient temperature is 5°, the decreasing temperature is 5° every time, and the ambient temperature of the filler passing through the pipe 1 is 50°, 45°, 40°, 35°, 30°, 25°, 20°, 15°, 10°, 5°; dense pressurization, continuously apply a pressure of 6MPa to the water-based filler in a closed environment through the pressurization equipment, and the ...

Embodiment 2

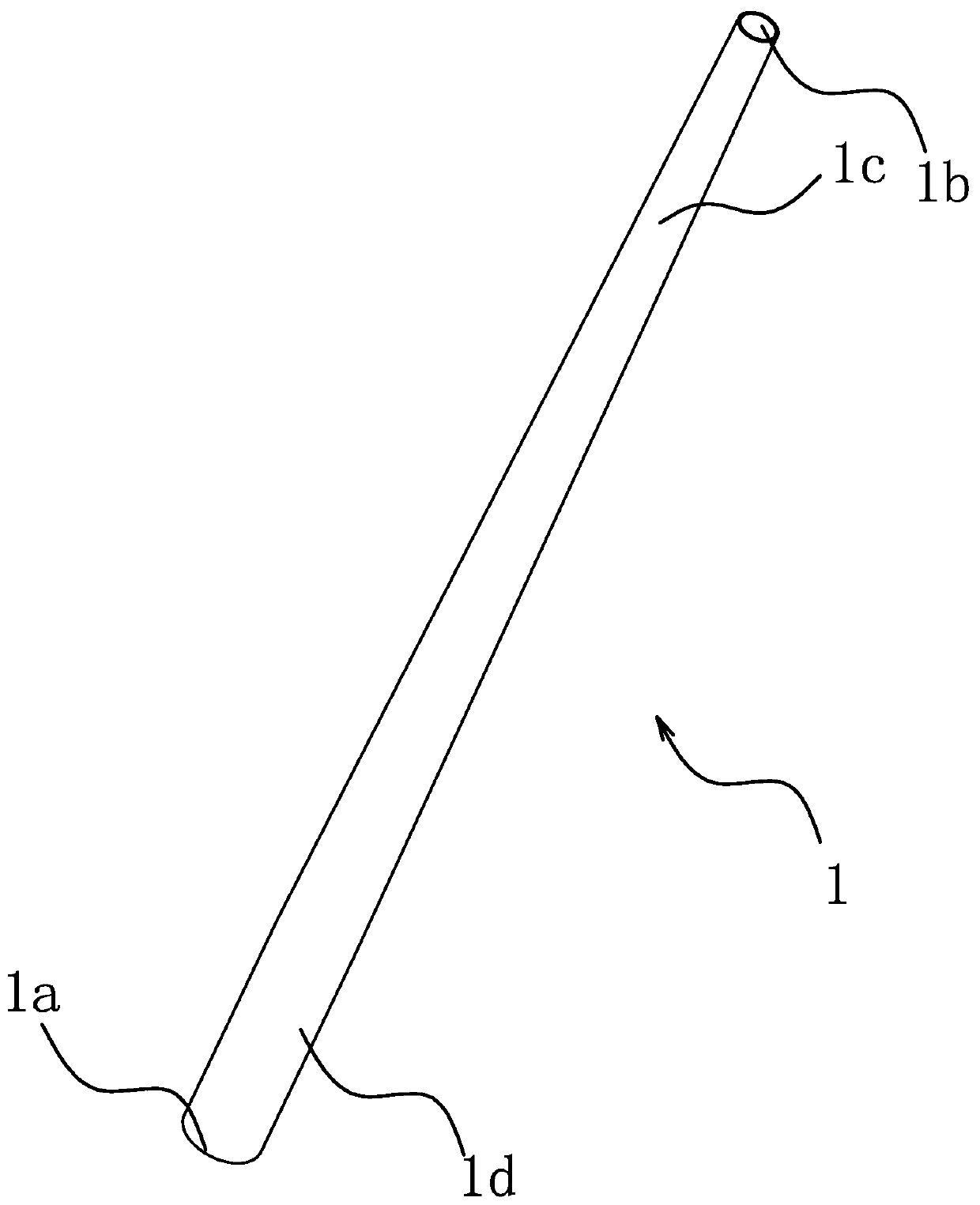

[0067] Such as figure 2 and image 3 As shown, the difference between the present embodiment and the first embodiment is that the pipe tool 1 is straight, and the extrusion efficiency of the water-based filler is high when the pipe tool 1 is straight.

[0068] The detailed structures, specific component sizes and principles not mentioned in this application document are all existing common knowledge or can be obtained by those skilled in the art through simple selection, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com