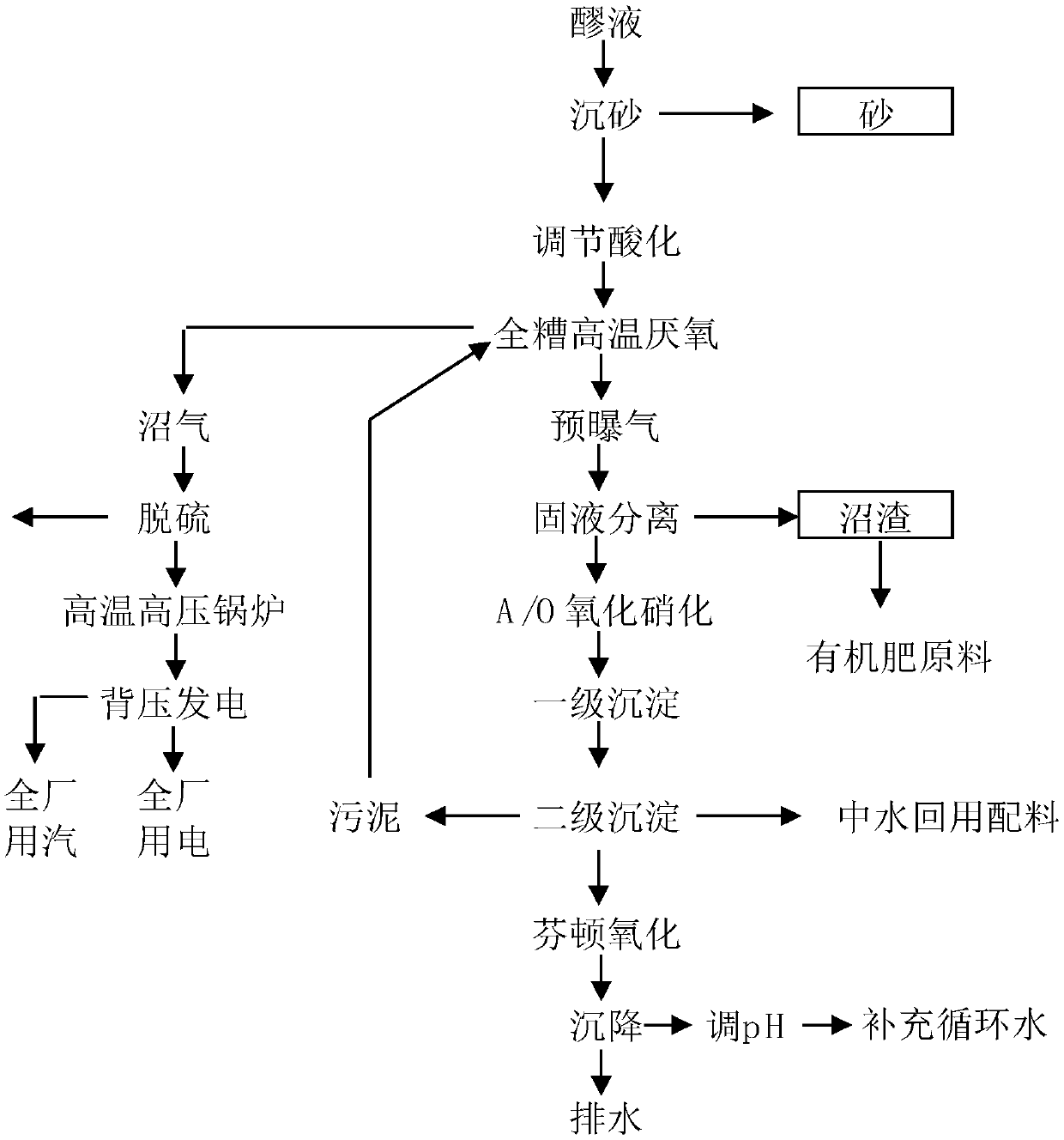

Method for coproducing alcohol and marsh gas by virtue of cassava and method for generating electricity by virtue of marsh gas

A cassava and biogas technology, applied in fermentation, biofuel, waste fuel, etc., can solve problems such as increased production costs, waste of resources, secondary pollution, etc., to improve solid-liquid separation flux, reduce energy consumption and costs, and avoid The effect of secondary pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0065] According to a preferred embodiment of the present invention, the water used for pulp preparation is the liquid phase after the first-stage sedimentation and the second-stage sedimentation or the clear liquid after the oxidation reaction and sedimentation, thereby greatly saving the consumption of fresh water.

[0066] In the present invention, the liquefaction is preferably jet liquefaction. Specifically, the cassava pulverized product is mixed with amylase and then jet liquefied to obtain a liquefied product. There is no particular limitation on the type and dosage of the amylase, which may be amylase and dosage commonly used in the art. Preferably, relative to 1 gram of the pulverized product, the amylase is used in an amount of 8-24 enzyme activity units. The amylase is preferably an alpha-amylase.

[0067] The α-amylase is also called starch 1,4-dextrinase, which can randomly and irregularly cut the α-1,4-glucosidic bond inside the starch chain, hydrolyze the star...

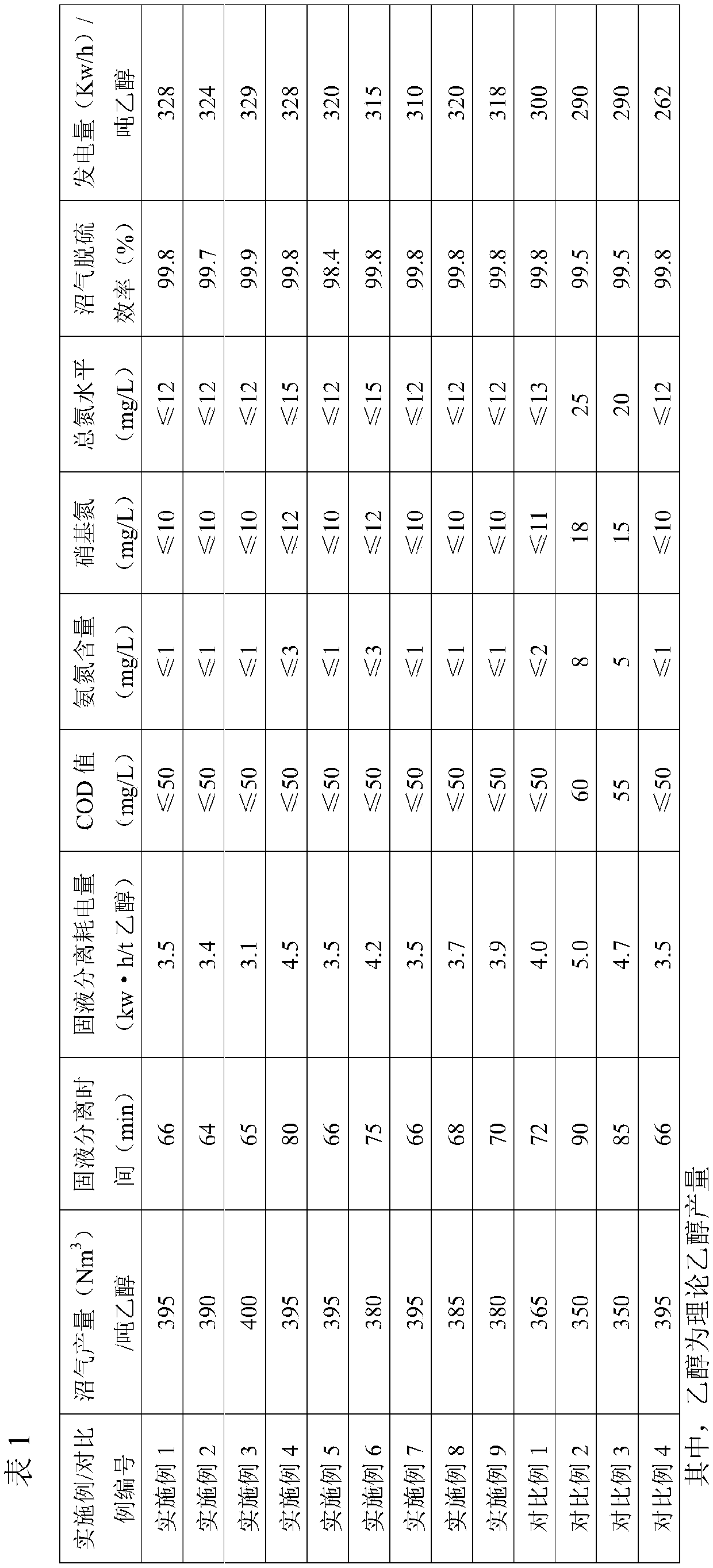

Embodiment 1

[0100] This embodiment is used to illustrate the method and power generation method of utilizing cassava to co-produce alcohol and biogas in the present invention

[0101] (1) Starch pulping

[0102] After being unloaded, the dried cassava chips are transported to the sieve by a self-unloading silo for sieving, wherein the underscreen is removed from the stones, iron pieces and braids, mixed with the oversize and crushed, passed through a 1.8mm sieve, and passed through a 1.8mm sieve. In the slurry tank, the temperature is 40° C., and the water containing 150 ppm bleaching powder is used to prepare a starch slurry with a solid content of 35% by weight.

[0103] (2) Jet liquefaction and saccharification

[0104] Mix the starch emulsion obtained in step (1) with α-amylase (high-temperature-resistant α-amylase, purchased from Genencor) and spray liquefy to obtain a liquefied product; wherein, the pulverization of 1 gram of cassava product, the dosage of the α-amylase is 20 enzy...

Embodiment 2

[0123] This embodiment is used to illustrate the method and power generation method of utilizing cassava to co-produce alcohol and biogas in the present invention

[0124] (1) Starch pulping

[0125] After being unloaded, the dried cassava chips are transported to the sieve by a self-unloading silo for sieving, wherein the underscreen is removed from the stones, iron pieces and braids, mixed with the oversize and crushed, passed through a 1.8mm sieve, and passed through a 1.8mm sieve. In the slurry tank, the temperature is 35° C., and the water containing 300 ppm bleaching powder is used to prepare a starch slurry with a solid content of 38% by weight.

[0126] (2) Jet liquefaction and saccharification

[0127] Mix the starch emulsion obtained in step (1) with α-amylase (high-temperature-resistant α-amylase, purchased from Genencor) and spray liquefy to obtain a liquefied product; wherein, the pulverization of 1 gram of cassava product, the dosage of the α-amylase is 15 enzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com