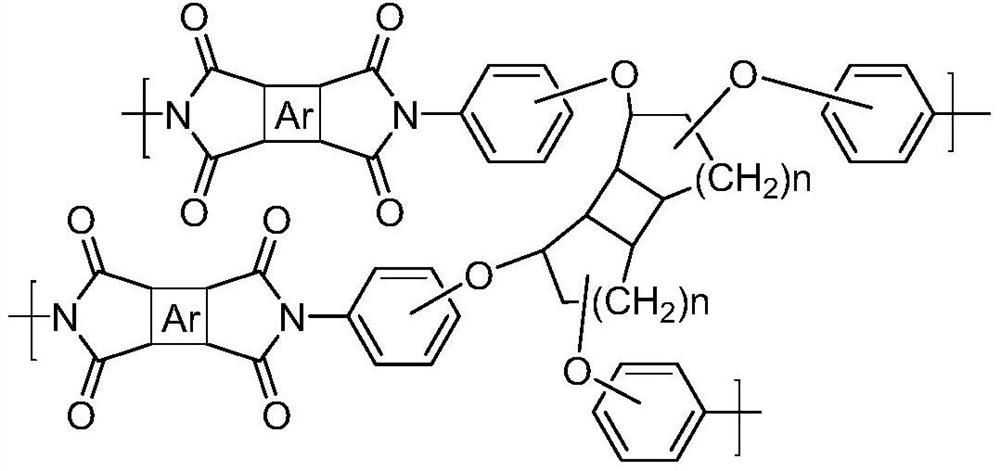

A kind of polyimide film and its preparation method and application

A polyimide film, polyimide technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor mechanical properties, poor heat resistance, and complex processes of polyimide. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

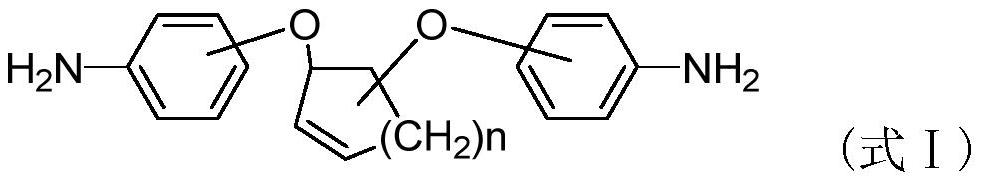

[0049] The synthesis method of the above-mentioned diamine monomer structural formula Ⅱ-1~Ⅱ-7 is similar, reference: J.Chem.Soc.,1958,3298-3313, the following formula Ⅱ-1 is taken as an example, the synthesis steps are as follows:

[0050] Mix 1mol of potassium p-nitro(phenyl)phenate and 0.5mol of 3,4-dibromocyclobutene in 400mL of anhydrous carbon tetrachloride and 400mL of anhydrous acetone, heat at 50°C and reflux for 6-8h, then filter , and the filtrate was evaporated in vacuo. The residue was dissolved in ether, washed successively with water, dilute aqueous sodium hydroxide solution, and water, then the ether solution was dried and evaporated, and crystallized from petroleum ether to obtain 3,4-bis(4-nitrophenoxy)cyclobutane- 1-ene.

[0051] Dissolve 0.5 mol of 3,4-bis(4-nitrophenoxy)cyclobut-1-ene in 200 mL of aqueous acetic acid (85%), add 50 g of iron for reduction, boil the suspension for 3 min, and Filtrate hot, cool, and slowly treat with 200 mL of concentrated h...

Embodiment 1

[0054] (1) Add 13.4060g (0.050mol) 4,4'-(cyclobutyl-3-ene-1,2-diyldioxy)diphenylamine (CBDA) monomer into a dry and clean 500mL three-neck flask, add After 225 g of N-methylpyrrolidone (NMP) was completely dissolved, 10.9060 g (0.050 mol) of pyromellitic dianhydride (PMDA) was added, and under the protection of nitrogen, react at 25°C for 12 hours to obtain a polyamic acid solution;

[0055] (2) above-mentioned polyamic acid solution is coated on dry and clean copper foil and glass flake respectively to form a film;

[0056] (3) Under a nitrogen atmosphere, dry the coated copper foil and glass sheet at 80°C for 6h; then heat to 150°C and keep it for 1h; then heat it to 200°C and keep it for 1h; then heat it to 250°C and keep it for 1h ; Finally, heat to 350°C, keep warm for 1h and then cool to room temperature. The film coated on the glass plate was boiled with boiling water until the polyimide film was removed from the glass plate to obtain a polyimide film with a thickness ...

Embodiment 2

[0058] (1) Add 14.1070g (0.050mol) 4,4'-(cyclopentyl-3-ene-1,2-diyldioxy)diphenylamine (CPDA) monomer into a dry and clean 500mL three-neck flask, add After 225 g of N-methylpyrrolidone (NMP) was completely dissolved, 10.9060 g (0.050 mol) of pyromellitic dianhydride (PMDA) was added, and under the protection of nitrogen, react at 25°C for 12 hours to obtain a polyamic acid solution;

[0059] (2) above-mentioned polyamic acid solution is coated on dry and clean copper foil and glass flake respectively to form a film;

[0060] (3) Under a nitrogen atmosphere, dry the coated copper foil and glass sheet at 80°C for 6h; then heat to 150°C and keep it for 1h; then heat it to 200°C and keep it for 1h; then heat it to 250°C and keep it for 1h ; Finally, heat to 350°C, keep warm for 1h and then cool to room temperature. The film coated on the glass plate was boiled with boiling water until the polyimide film was removed from the glass plate to obtain a polyimide film with a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com