Steel plate straightening device

A straightening device and technology for steel plates, applied in cleaning methods and tools, manufacturing tools, metal processing, etc., can solve the problems of reduced quality of steel plate processing and difficulty in ensuring steel plate straightening, so as to reduce the probability of misalignment and improve Quality, the effect of avoiding gas backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

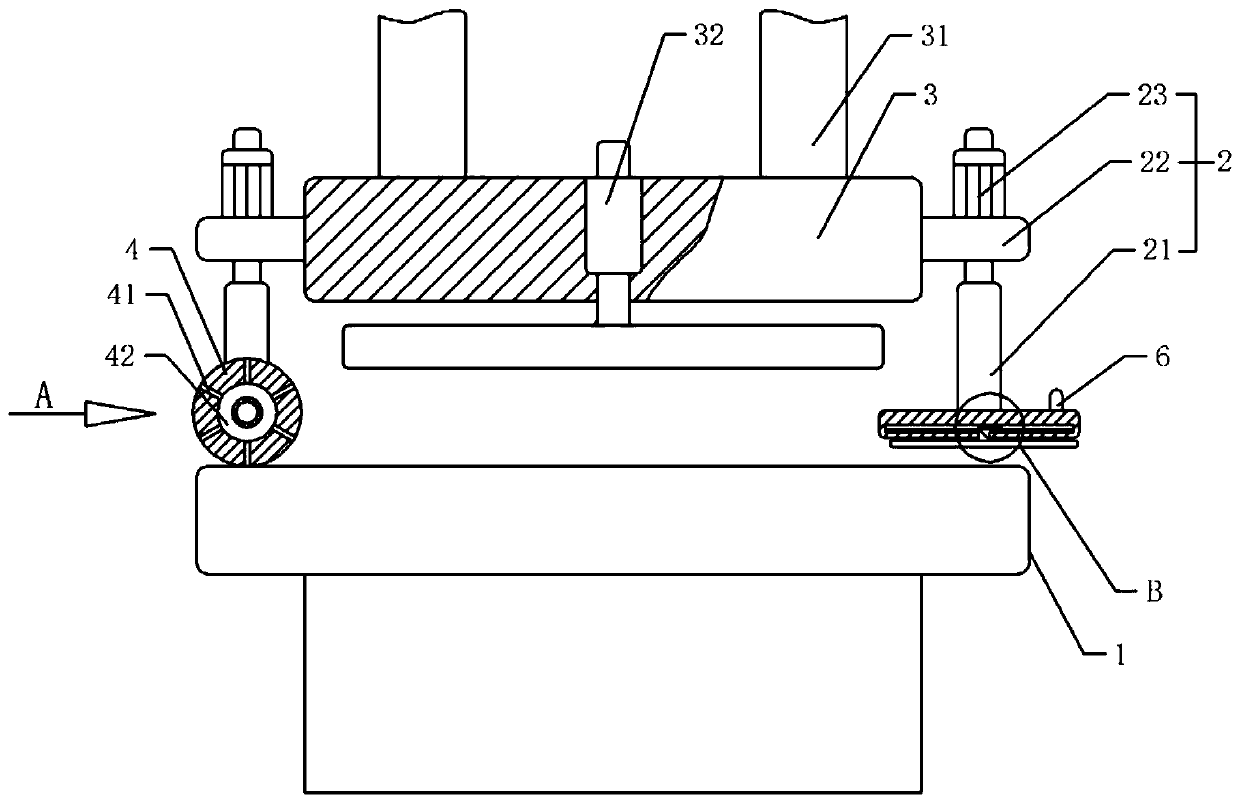

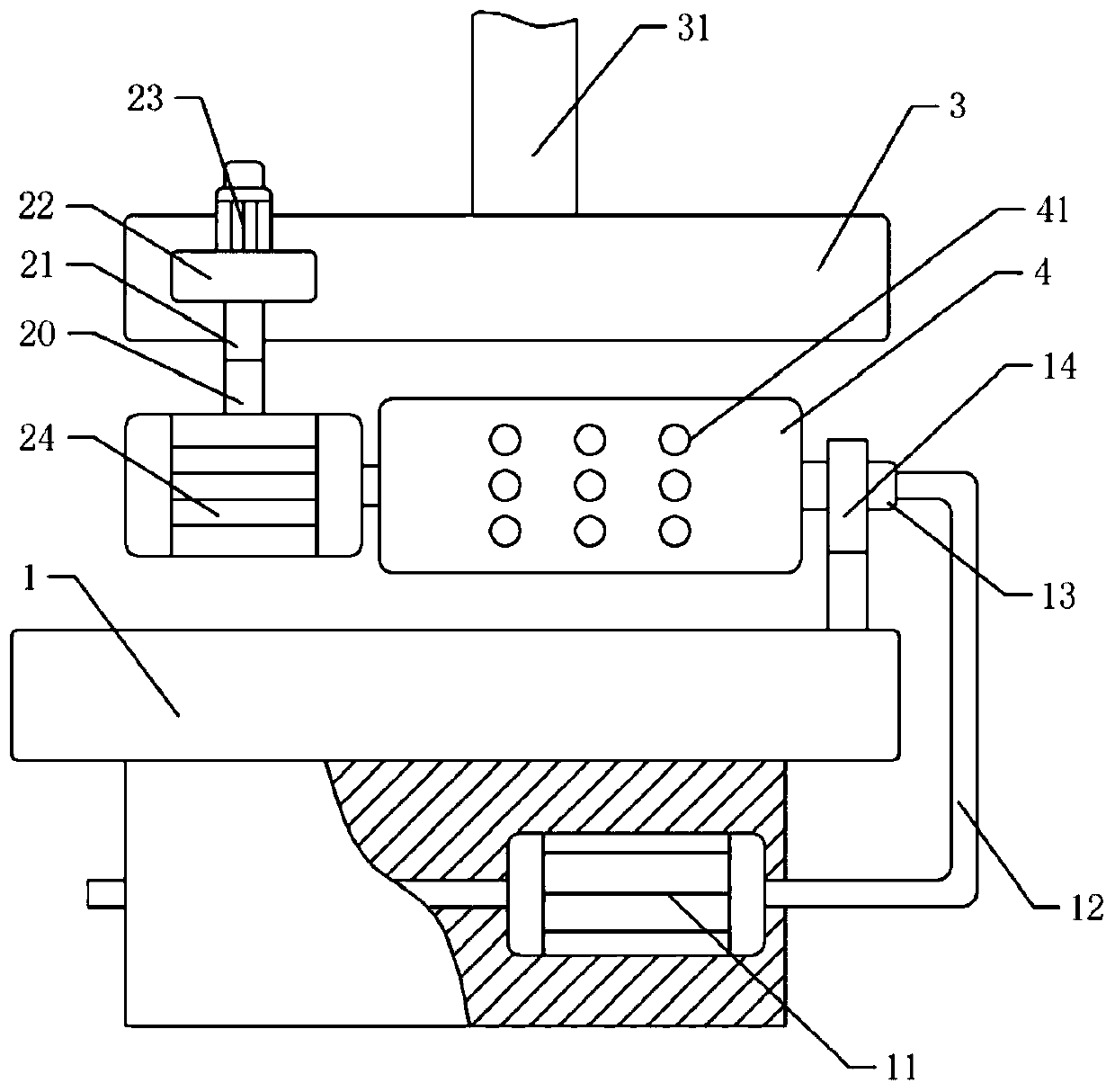

[0039] Basic as attached figure 1 , attached figure 2 And attached image 3 As shown, a steel plate straightening device includes a frame, a placement platform 1 and a hydraulic mechanism located above the placement platform 1. The hydraulic mechanism includes a first hydraulic cylinder 31 and a moving plate fixed on the output shaft of the first hydraulic cylinder 31 by bolts. 3.

[0040] The moving plate 3 is provided with a straightening mechanism, and the straightening mechanism includes a driver bolted on the moving plate 3. In this embodiment, the driving piece is the third hydraulic cylinder 32, and the output shaft of the third hydraulic cylinder 32 is bolted with a Alignment board. Both sides of the moving plate 3 are provided with an adjusting mechanism 2, the adjusting mechanism 2 includes an adjusting plate 22 bolted on the moving plate 3, the adjusting plate 22 is bolted with a second hydraulic cylinder 23, and the output shaft of the second hydraulic cylinder...

Embodiment 2

[0049] The difference between embodiment two and embodiment one is that, as attached Figure 5 As shown, a recovery box 71 is provided on one side of the placement table 1, and the recovery box 71 is filled with a dedusting solution. In this embodiment, the dedusting solution is water. The bottom bolt of recovery box 71 is fixed with intake check valve 72, and the air outlet of negative pressure pump 11 is communicated with intake check valve 72 by pipeline, and the top of recovery box 71 has gas port, and gas port is communicated with gas storage box 75. Connected gas outlet pipe 73, gas storage box 75 bolts are fixed on the placement table 1, and the gas outlet box is communicated with a valve, and the valve bolt is fixed on the gas outlet box (not shown in the figure), and the valve is connected with a shower nozzle 74.

[0050] The specific implementation process is as follows:

[0051] The negative pressure pump 11 enters the gas in the leveling roller 4 into the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com