Patterning method, etching method, manufacturing method of display panel and display panel

A technology for display panels and graphics, which is applied in the fields of graphics, etching, display panels, and display panels. It can solve the problems of rough exposure edges, impermeable exposure, and unclean development, and achieve uniform and more thorough exposure and enhanced exposure. Strength, roughness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

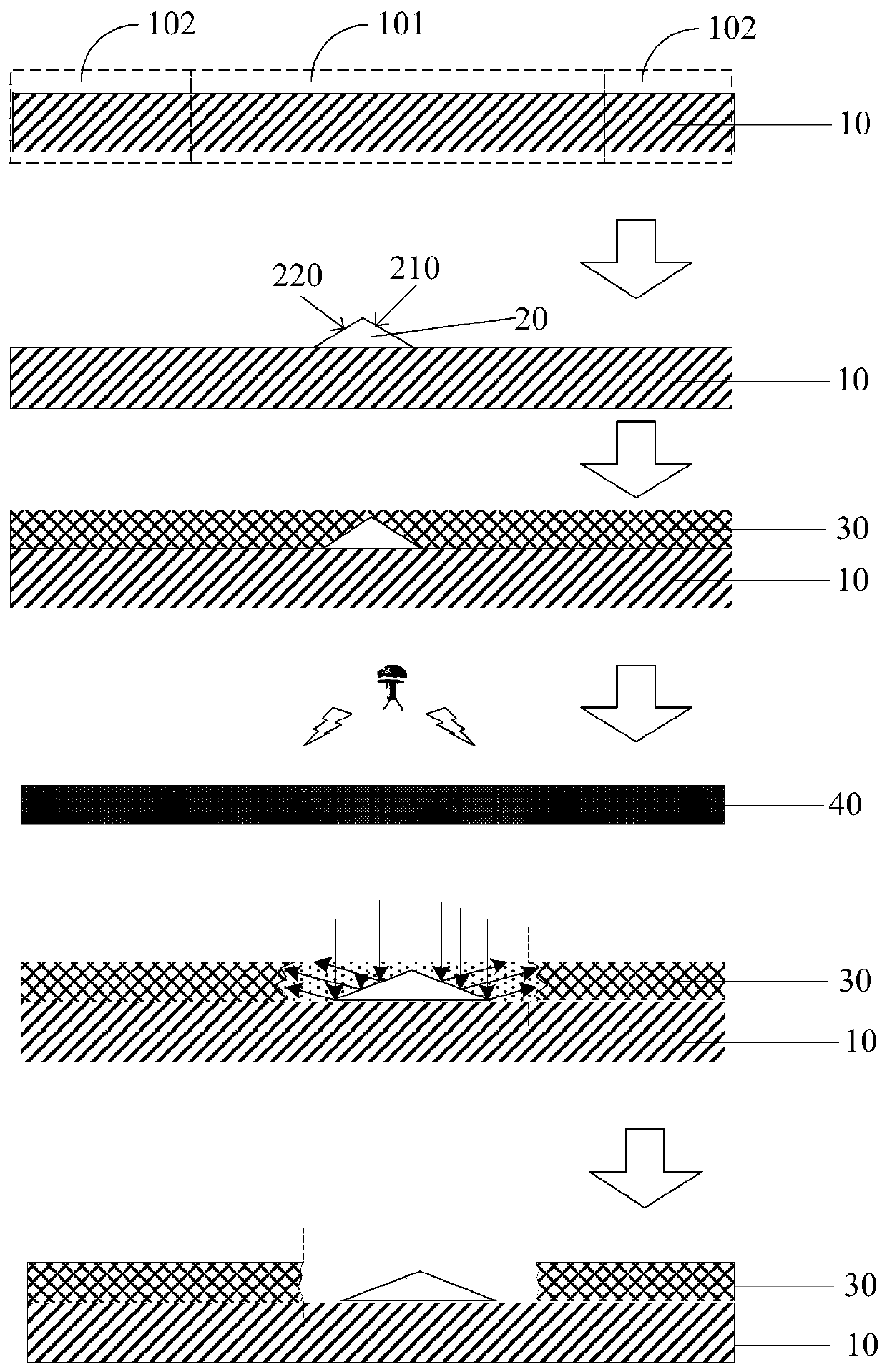

[0021] In order to make the purpose, technical solution and effect of the present application more clear and definite, the present application will be further described in detail below with reference to the accompanying drawings and examples.

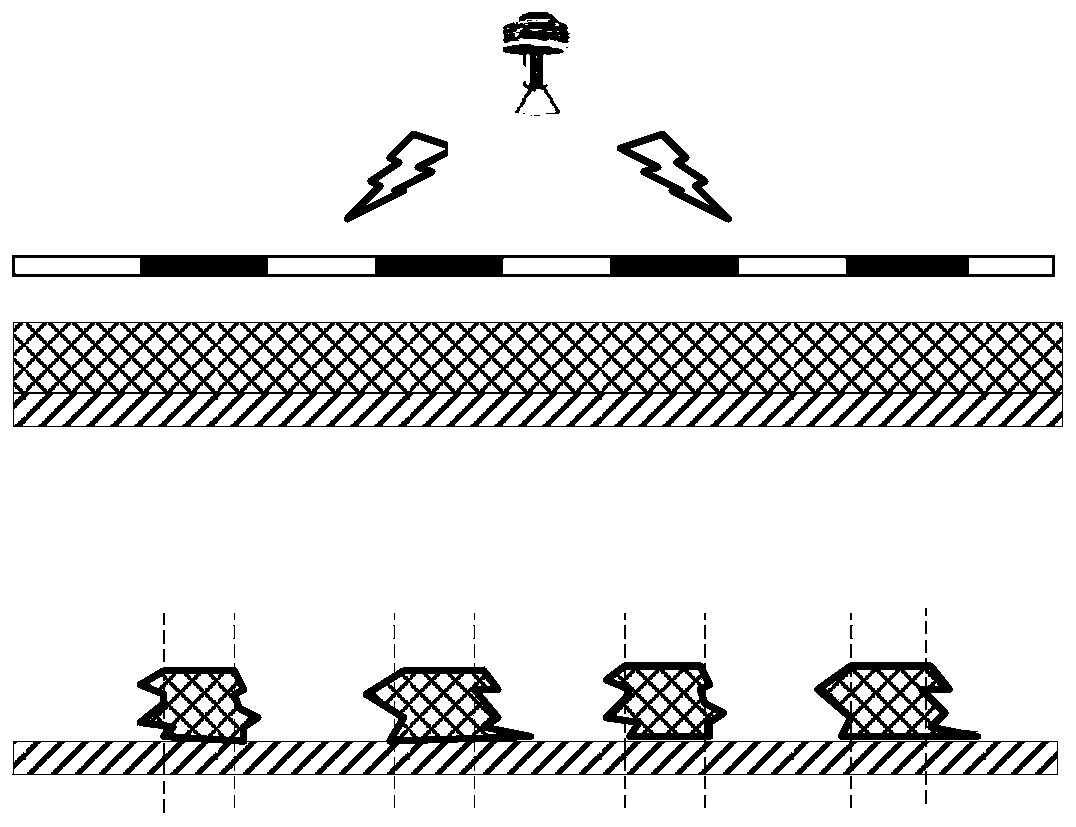

[0022] The present application provides a patterning method, which can improve the exposure accuracy of the photoresist layer. The method is realized by setting reflective blocks in the photoresist layer and using the reflective blocks to reflect exposure light in different directions.

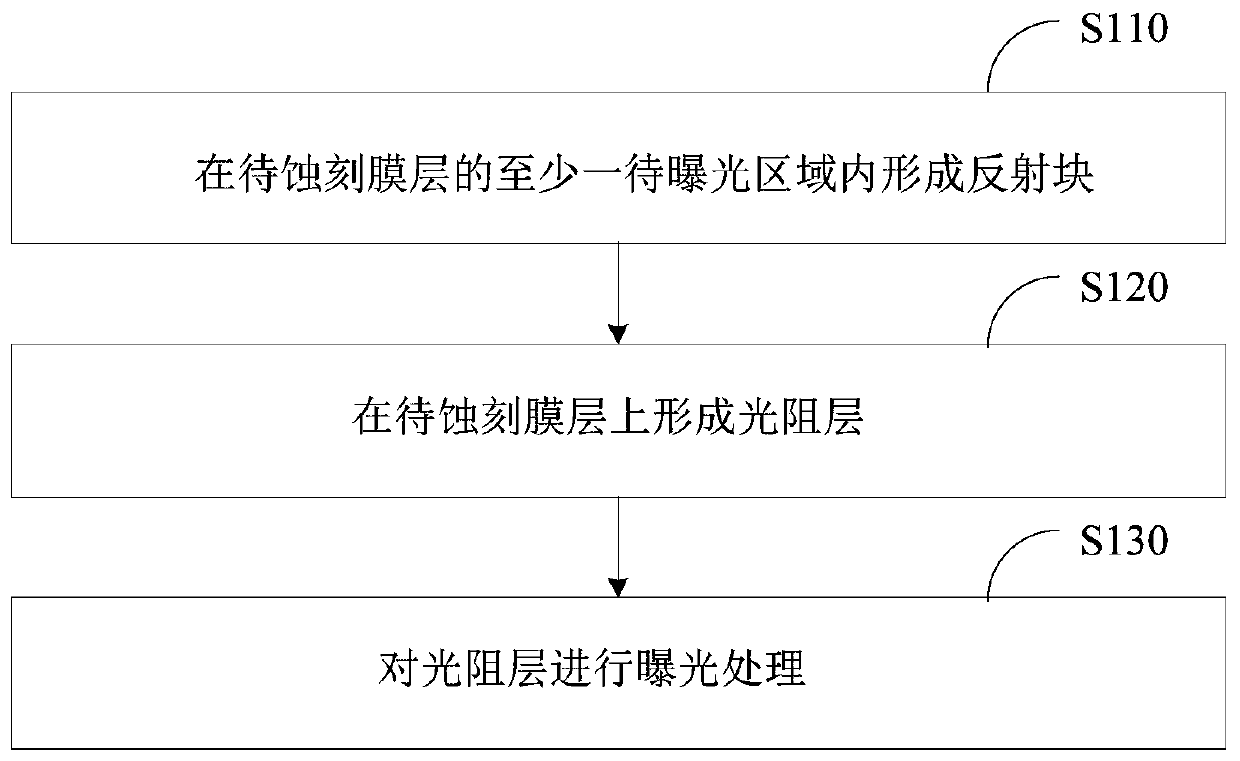

[0023] see figure 2 , figure 2 It is a schematic flowchart of the graphical method in the embodiment of the present application. In this embodiment, the graphical method includes:

[0024] S110: Form a reflective block in at least one area to be exposed of the film layer to be etched.

[0025] S120: forming a photoresist layer on the film layer to be etched.

[0026] Wherein, the photoresist layer covers the film layer to be etched and wraps the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com