Light-curing three-dimensional printing method and device

A 3D printing and light-curing technology, which is applied in processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve problems such as deformation and light-curing resin warping, and achieve reduced temperature rise, reduced shrinkage, and deformation problems Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

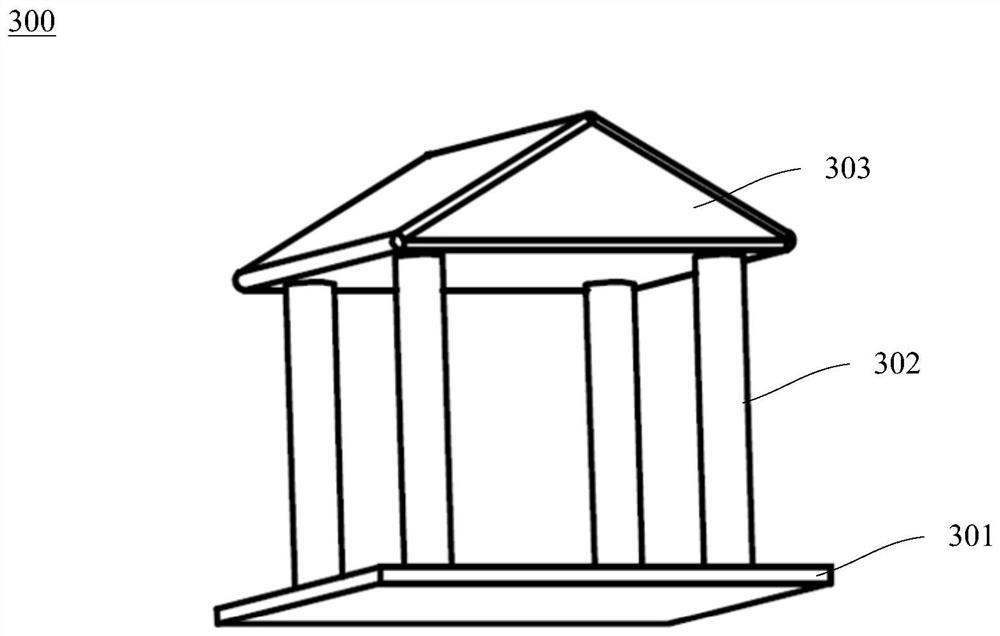

[0031] The embodiment of the present invention describes a light-curing three-dimensional printing method, which can reduce the internal stress generated when the light-curing resin is cured in a large area, thereby improving the degree of warpage and deformation of the printed workpiece.

[0032] figure 1 The basic structure of the photo-curing 3D printing device is shown. This 3D printing device 100 includes a material tank 110 for accommodating photocurable resin, an image exposure system 120 for curing the photocurable resin, and a lift table 130 for connecting molded workpieces. The image exposure system 120 is located above the material tank 110 and can irradiate a beam image to cure a layer of photocurable resin on the liquid surface of the material tank 110 . Every time the image exposure system 120 irradiates the light beam image to cause a layer of photocurable resin to cure, the lifting table 130 will drive the formed layer of photocurable resin to drop slightly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com