Device and method for reducing heat load of natural gas engine by alcohol doping

A natural gas and engine technology, which is applied in the field of engine substitute fuels, can solve the problems of low flame propagation speed of natural gas, lengthened rapid combustion period, and reduced combustion iso-volume, etc., so as to broaden the selection range, ensure stable working operation, and increase iso-volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The examples are only used to explain the present invention, not to limit the protection scope of the present invention.

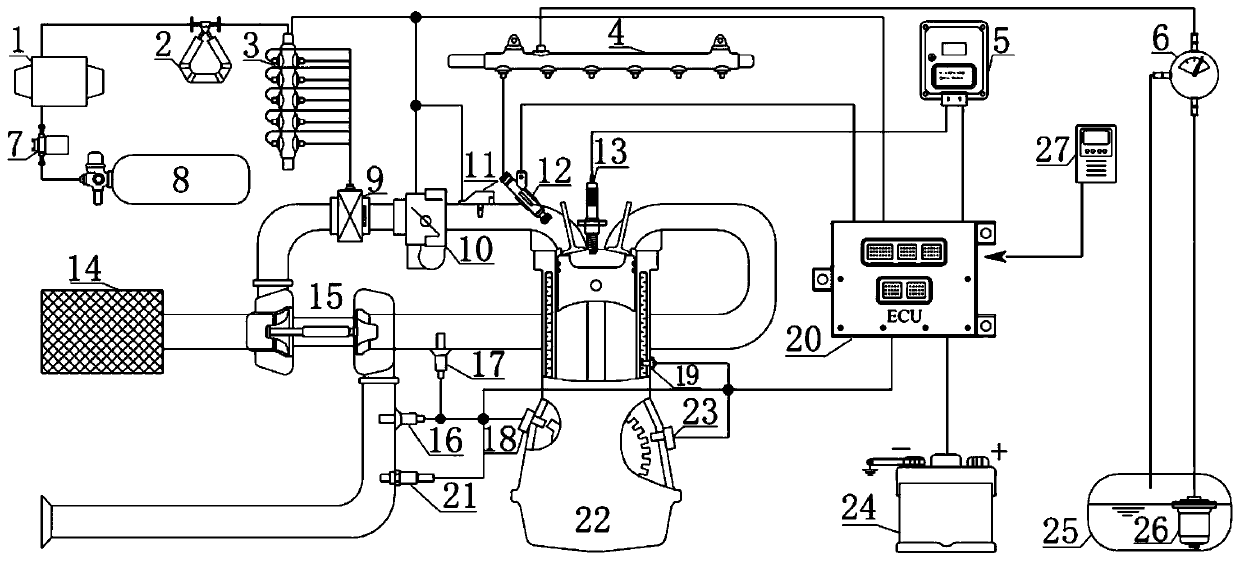

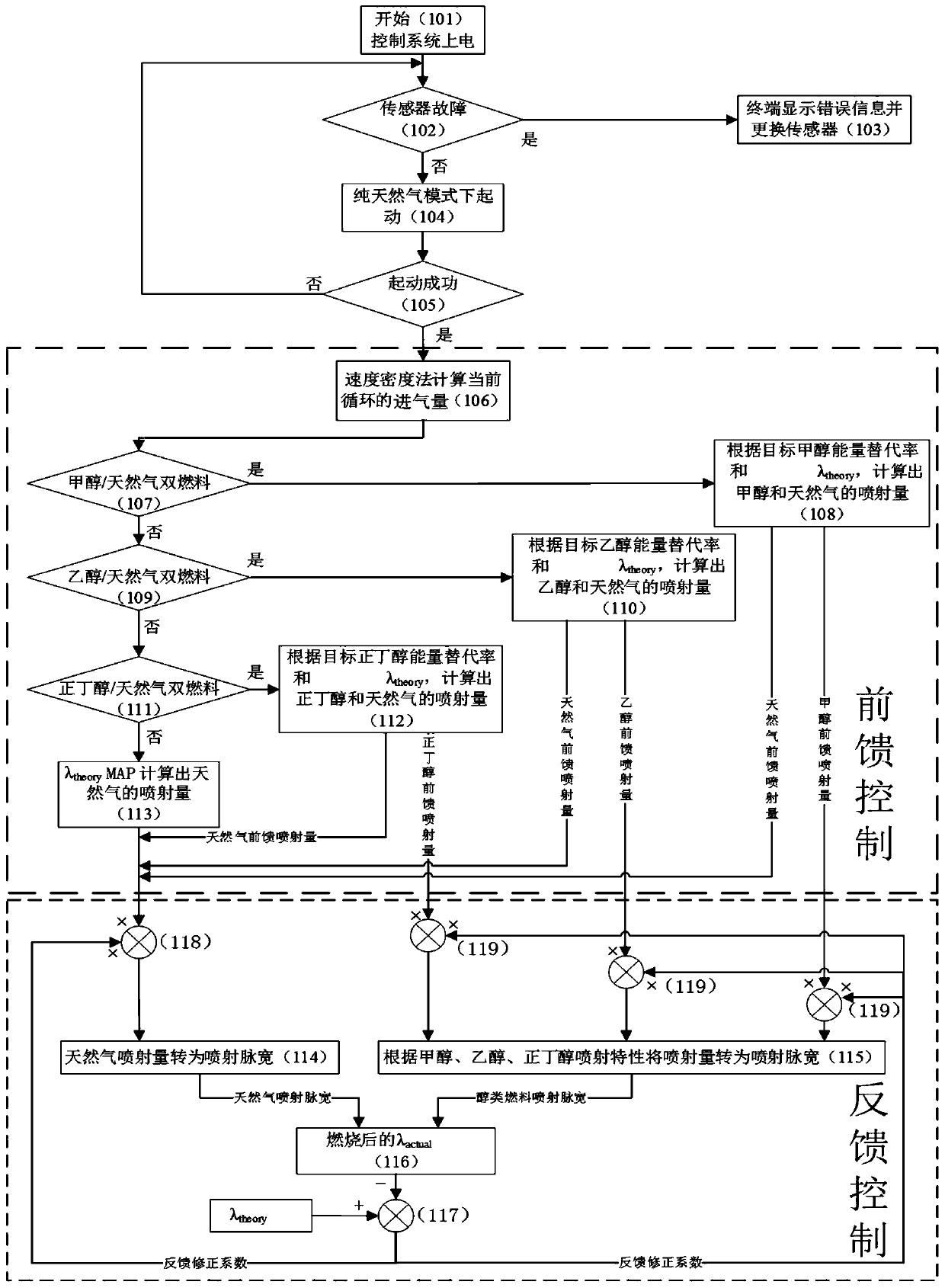

[0036] see figure 1 , the present invention proposes a natural gas / alcohol dual-fuel engine, which is specifically implemented by using an electronic control system to control the alcohol blending of the ignition type natural gas engine body 22 . The electronic control system includes an electronic control unit 20 (that is, an ECU) for receiving sensor signals and performing control operations to output actuator control signals. The electronic control unit 20 is respectively connected with the crankshaft position sensor 23 (which can be used for the ECU to measure the engine speed), the camshaft position sensor 18 (cooperating with the crankshaft position sensor 23 for the ECU to determine the engine running phase and timin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com