Peach gum polysaccharide with efficient anti-allergy and itching-relieving effects, and fermentation extraction method and application thereof

A technology of peach gum polysaccharide and extraction method, applied in the field of bioengineering, can solve the problems of wide molecular weight distribution and poor homogeneity of the product, and achieve the effects of narrow molecular weight range, low emission, and improved anti-allergic and antipruritic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Preparation of engineering yeast dry powder

[0035] 1) Preparation of yeast clones, extract the genomic DNA of the expression vector galactanase (sequence from NCBI: XM_025647395.1), digest with nuclease to obtain linearized DNA, and dissolve the linearized DNA in 5-10 μL TE (purchased from Neopro Biotech). Take 80 μL of commercially competent Pichia pastoris GS115 (purchased from Tiangen Biotechnology) and mix it with 10 μg of linearized DNA, and transfer it into a pre-cooled 0.2 cm electroporation cup. Place on ice for 5 min. Set the machine parameters, immediately add 1ml of pre-cooled 1M sorbitol to the cup, transfer the contents to a sterilized centrifuge tube and divide it into 200μL aliquots, spread it on the MD plate (basic glucose medium), and incubate the plate at 30°C Until the clone is produced, because the transformed vector contains the mut gene, only the successfully transformed strains can be screened by the mut phenotype, so the Mut+ / Mut...

Embodiment 2

[0037] Example 2 Extraction of Peach Gum Polysaccharide by High Pressure Water Extraction

[0038] After the peach gum is removed from debris, take about 100g of peach gum and add appropriate amount of water to soak overnight, add ultra-pure water according to the ratio of solid to liquid at 1:20, stir and extract with hot water at 80°C, the extraction time is 4 hours, and the number of times is 2 times. Due to the high viscosity of the solution, first filter it with 2 layers of gauze, then centrifuge the filtrate at 8000r / min for 15 minutes, pour out the supernatant, reduce the pressure and rotary evaporate to about 1 / 3 of the original volume, pour it out, and add absolute ethanol to The mass fraction of ethanol was 90%, and the supernatant was poured off after standing overnight. The lower precipitate was washed with absolute ethanol and vacuum filtered, then freeze-dried to obtain peach gum polysaccharide. The total sugar content of peach gum polysaccharide was determined ...

Embodiment 3

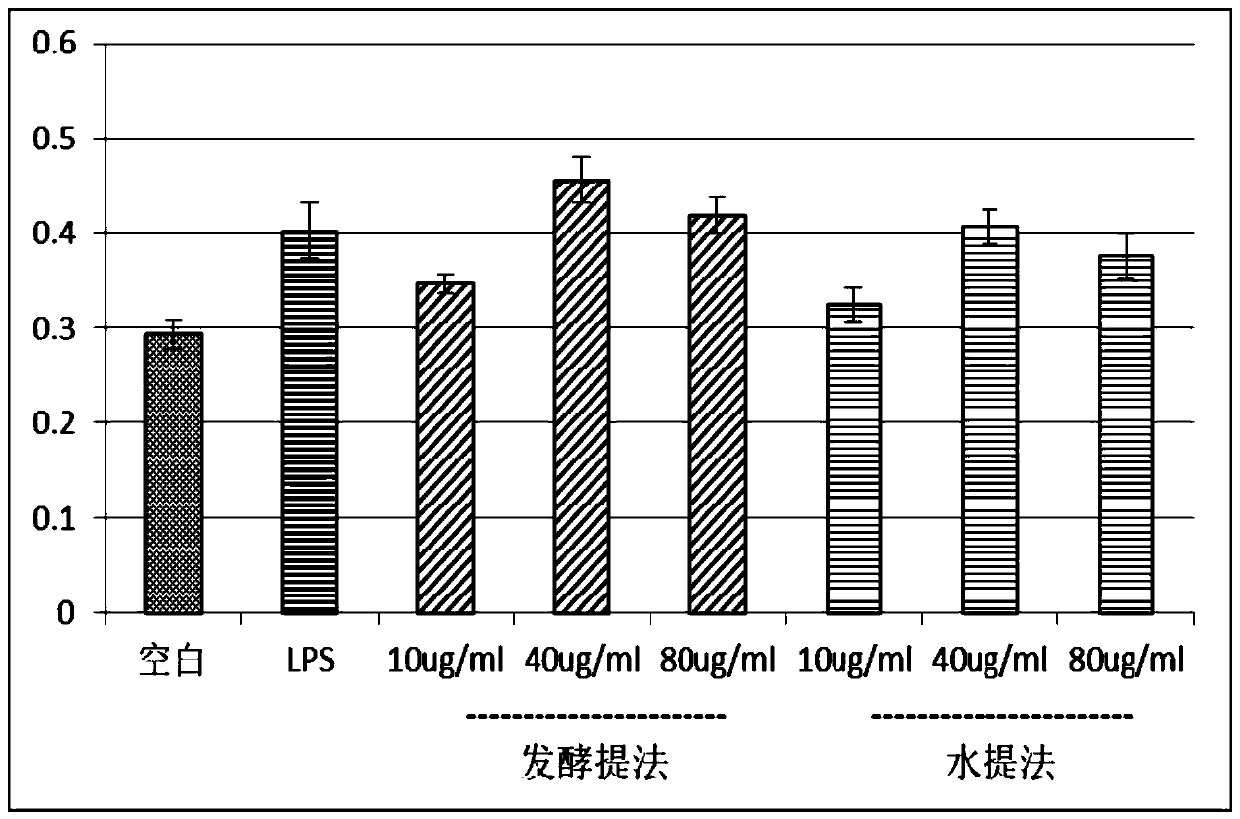

[0042] Example 3 Extraction of Fermented Peach Gum Polysaccharide

[0043] After the peach gum is removed from debris, take about 100g of peach gum and add appropriate amount of water to soak overnight, and add ultra-pure water according to the material-liquid ratio of peach gum, ultrapure water and yeast dry powder expressing galactanase 1:10:0.01 and yeast dry powder, and then poured into a 5L fermenter, adjusting the temperature to 30°C, rotating at 250rpm, stirring and fermenting for 10h. Measure the viscosity of the feed liquid, and stop the fermentation when the viscosity drops below 500mPa.s. Pour out feed liquid, centrifuge 10 minutes with high-speed centrifuge 6000rpm. Discard the bacterial sediment at the bottom, and use a roll-type filter membrane (pore size 0.22 microns) for microfiltration to remove residual bacterial cells and granular components without causing bacterial contamination. Add absolute ethanol until the mass fraction of ethanol is 70%, and pour of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com