Inorganic single-component ink for precision casting and preparation method thereof

A precision casting, one-component technology, applied in the direction of casting molding equipment, application, ink, etc., can solve the problems of printing ink not resistant to high temperature, poor surface quality of castings, thermal deformation and collapse, etc., to reduce workflow, low cost, The effect of improving casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

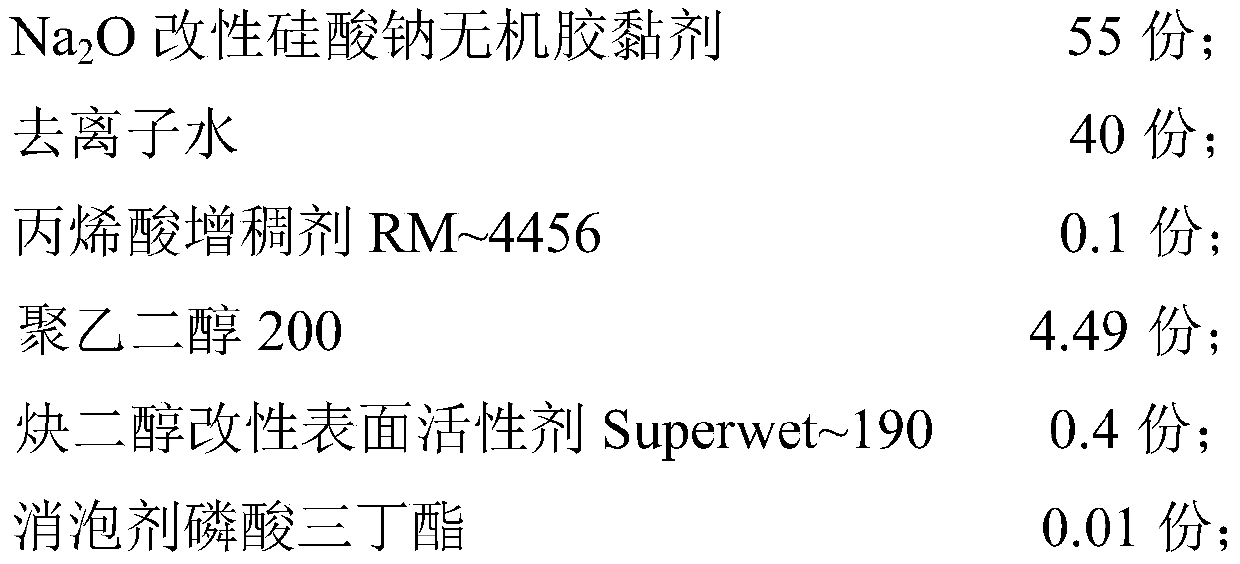

[0031] (1) Inorganic ink formula (by weight):

[0032]

[0033] (2) Preparation method:

[0034] Step 1: Take quantitative Na by weight ratio 2 The O-modified sodium silicate inorganic adhesive is placed in the batching tank, the stirrer is turned on, the stirring speed is 1000r / min, and the stirring is continued for 10min; 2 Add a certain amount of deionized water to the O-modified sodium silicate inorganic adhesive, and stir for 15 minutes after the addition is complete;

[0035] Step 2: Take quantitative acrylic thickener RM-4456 thickener according to the weight ratio, slowly add it to the above stirring liquid several times, after stirring for 60 minutes, slowly add quantitative polyethylene glycol 200, after stirring for 15 minutes, slowly add quantitative alkyne Diol-modified surfactant Superwet~190, stir for 10 minutes;

[0036] Step 3: Slowly add the quantitative defoamer tributyl phosphate into the above stirring liquid, stir for 20 minutes, take out the prepar...

Embodiment 2

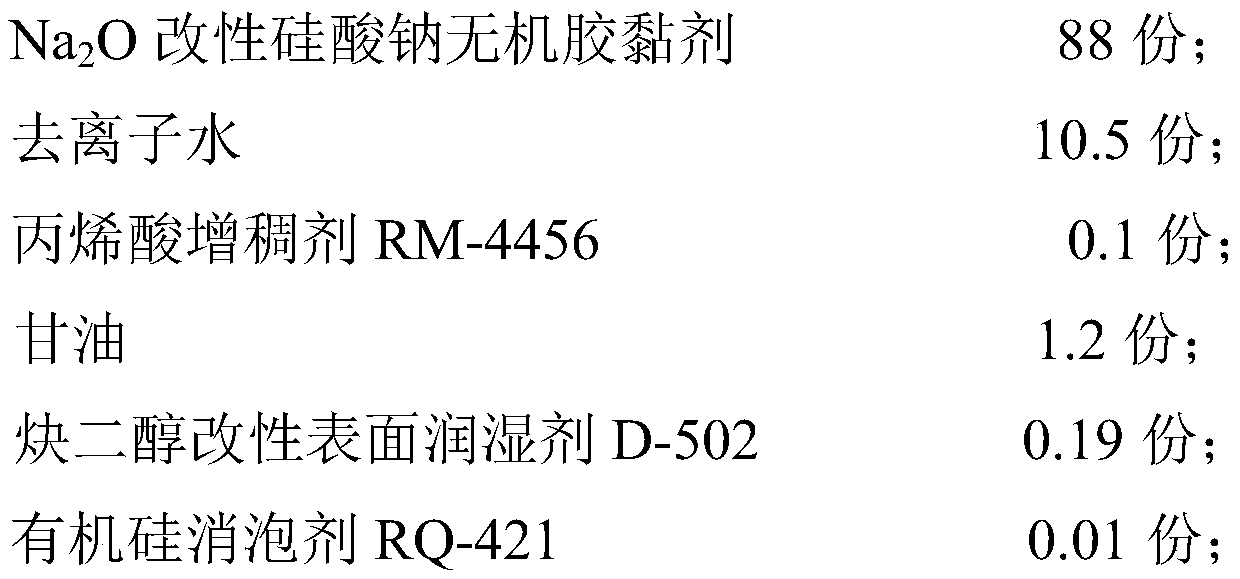

[0042] (1) Inorganic ink formula (by weight):

[0043]

[0044] (2) Preparation method:

[0045] Step 1: Take quantitative Na by weight ratio 2 The O-modified sodium silicate inorganic adhesive is placed in the batching tank, the stirrer is turned on, the stirring speed is 800r / min, and the stirring is continued for 10min; 2 Add a certain amount of deionized water to the O-modified sodium silicate inorganic adhesive, and stir for 15 minutes after the addition is complete;

[0046] Step 2: Take the quantitative acrylic thickener RM-4456 thickener according to the weight ratio, slowly add it to the above stirring liquid several times, after stirring for 60 minutes, slowly add the quantitative glycerin dispersant, after stirring for 15 minutes, slowly add the quantitative acetylene glycol Modified surface wetting agent D-502, stirred for 10 minutes;

[0047] Step 3: Take quantitative silicone defoamer RQ-421 and slowly add it to the above stirring liquid, stir for 10 minute...

Embodiment 3

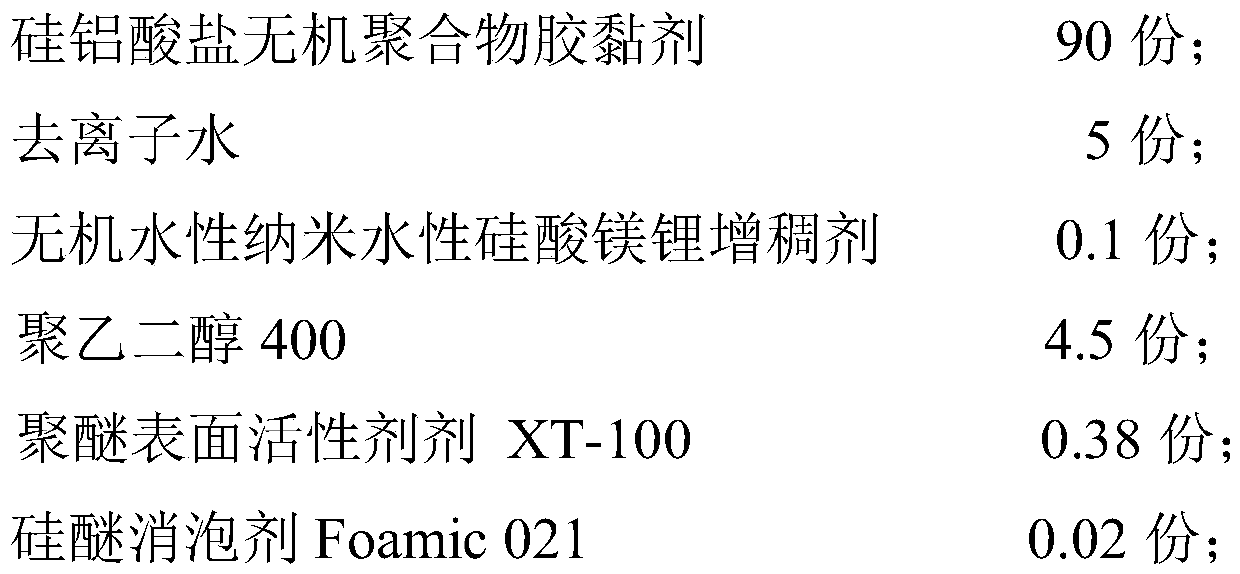

[0053] (1) Inorganic ink formula (by weight):

[0054]

[0055] (2) Preparation method:

[0056] Step 1: Take a quantitative aluminosilicate inorganic polymer adhesive according to the weight ratio and place it in the batching tank, turn on the stirrer, stir at a speed of 900r / min, continue stirring for 15min, and slowly pour the aluminosilicate inorganic polymer into the stirring Add a certain amount of deionized water to the polymer adhesive, and stir for 5 minutes after adding;

[0057] Step 2: Take the inorganic water-based nano-lithium magnesium silicate thickener according to the weight ratio, slowly add it to the above stirring liquid several times, after stirring for 90 minutes, slowly add quantitative polyethylene glycol 400 dispersant, after stirring for 20 minutes, slowly add quantitative Polyether surfactant XT-100, stirred for 15 minutes;

[0058] Step 3: Take the quantitative silicon ether defoamer Foamic 021 and slowly add it to the above stirring liquid, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com