A microporous carbon adsorbent for separating alkenes and alkanes, its preparation method and application

A technology of alkenes, alkanes, and microporous carbons, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as low selectivity, complex amorphous structure, lack of fine control, etc., and achieve low gas mass transfer resistance , Fast diffusion and mass transfer rate, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

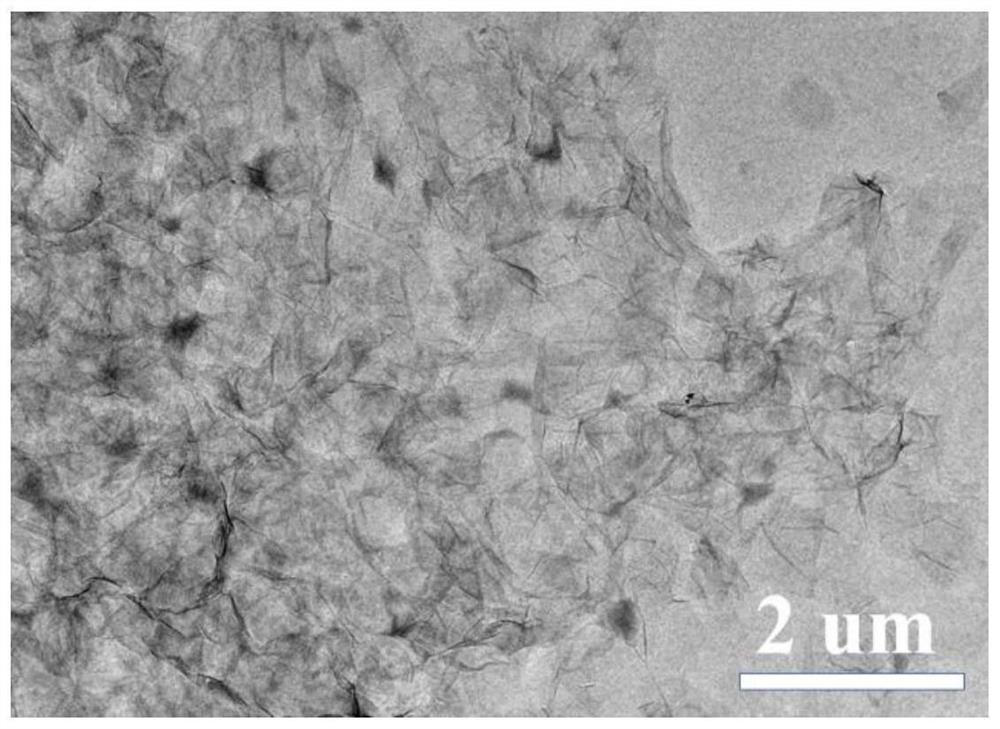

[0086] (1) Preparation of polymer

[0087] Take 1.5g of acetone, 0.1g of deionized water and 1.3mL of graphene oxide dispersion into the reactor, stir well, then add 0.59g of aniline and 1g of resorcinol to the reactor, stir well, then add 1.35 g formaldehyde solution, stir evenly, heat up to 40°C, react for 8h, then pour the above polymer into a quartz tube reactor, put it in a constant temperature oven for gel aging, the aging temperature is 90°C, the aging time is 18h, and the aging is over Finally, the polymer was taken out, dried to a constant weight for later use, and the sample number was named UMC-1.

[0088] (2) Preparation of microporous carbon adsorbent

[0089] The prepared polymer UMC-1 was placed in a porcelain boat in a carbonization furnace, under argon atmosphere purging, at 3 °C min -1 The heating rate was raised from room temperature to 700°C and kept for 2 hours to prepare a microporous carbon adsorbent, the sample number of which was UMC-1-700-3.

[0090]...

Embodiment 2

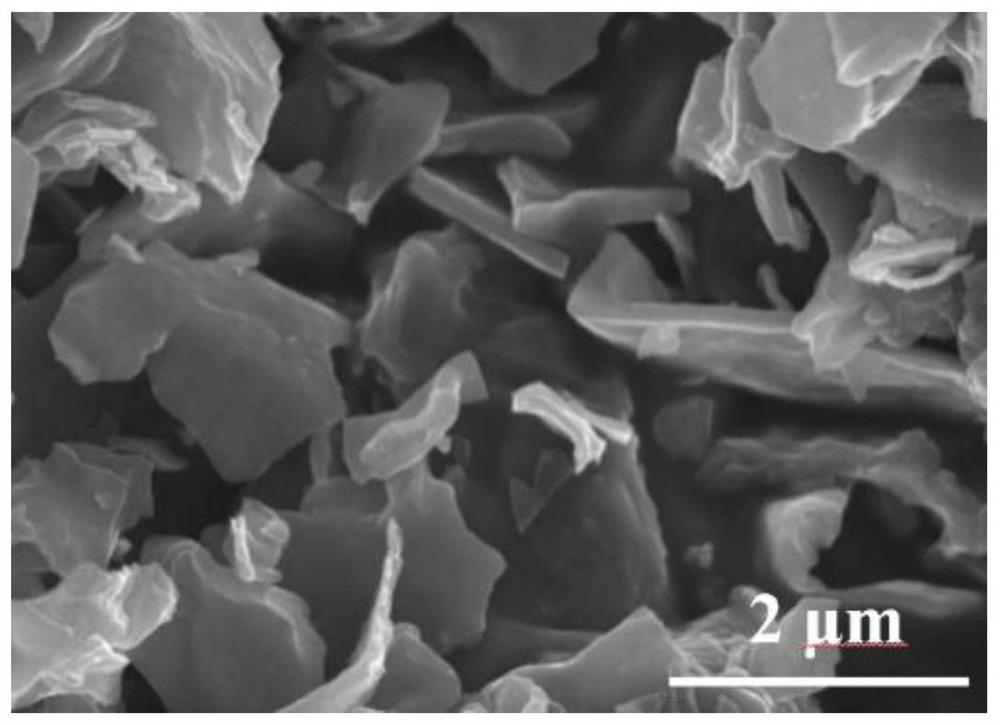

[0092] (1) Preparation of polymer

[0093] Take 0.022g of boron nitride, 1.5g of acetone and 1.5g of deionized water into the reactor, stir well, then add 1.2g of p-phenylenediamine and 1.3g of mixed cresol into the reactor, stir well, then add 1.35g formaldehyde solution, stir evenly, heat up to 40°C, react for 8h, then pour the above polymer into a quartz tube reactor, put it in a constant temperature oven for gel aging, the aging temperature is 90°C, the aging time is 18h, aging After the end, the polymer was taken out, dried to a constant weight for later use, and the sample number was named UMC-2.

[0094] (2) Preparation of microporous carbon adsorbent

[0095] The prepared polymer UMC-2 was placed in a porcelain boat in a carbonization furnace, and under an argon atmosphere purging, the -1 The heating rate was raised from room temperature to 700°C and kept for 2 hours to prepare a microporous carbon adsorbent, and the sample number was named UMC-2-700-3.

[0096] Spe...

Embodiment 3

[0098] (1) Preparation of polymer

[0099] Get 1.5g acetone, 0.3g deionized water and 1mL graphene oxide dispersion liquid and join in the reactor, stir evenly, then add 1.8g m-phenylenediamine and 1g phloroglucinol successively in the reactor, stir evenly, then Add 1.35g of formaldehyde solution, stir evenly, heat up to 40°C, react for 8h, then pour the above polymer into a quartz tube reactor, put it in a constant temperature oven for gel aging, the aging temperature is 90°C, and the aging time is 18h. After aging, the polymer was taken out and dried to constant weight for later use. The sample number was named UMC-3.

[0100] (2) Preparation of microporous carbon adsorbent

[0101] The prepared polymer UMC-3 was placed in the porcelain boat of the carbonization furnace, under the argon atmosphere purging, at 3 °C min -1 The heating rate was raised from room temperature to 700°C and kept for 2 hours to prepare a microporous carbon adsorbent, and the sample number was named...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com