Preparation method of cubic ternary positive electrode material precursor

A positive electrode material and cube technology, which is applied in the field of new energy material preparation, can solve the problems of increased metal ion dissolution, decreased electrochemical performance, and easily broken secondary particles, achieves excellent stability, improves compaction density, compaction density, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

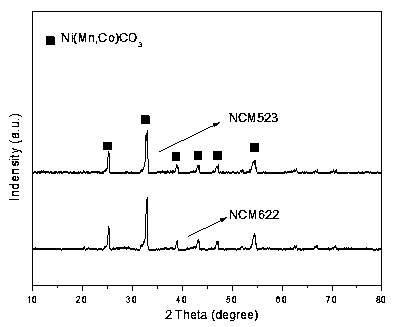

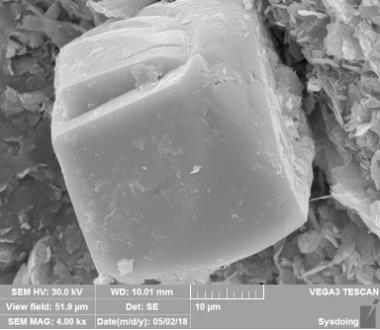

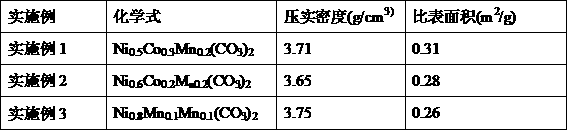

[0022] NiSO 4 , CoSO 4 , MnSO 4 Prepare a nickel-cobalt-manganese mixed aqueous solution according to the molar ratio Ni:Co:Mn=5:3:2, the total concentration is 0.2 mol / L, add 0.2g CTAB (cetyltrimethylammonium bromide), and add 1.2 g urea , stirring and dissolving to obtain a translucent solution. Stand still for 24 hours, aged at 90°C for 24 hours to obtain a khaki precipitate, evaporate and crystallize at 90°C, wash and dry to obtain a cubic ternary cathode material precursor. The shape is cubic, the particle size distribution is narrow, and the compacted density is 3.71 g / cm 3 , with a specific surface area of 0.31 m 2 / g, such as figure 2 shown.

Embodiment 2

[0024] NiSO 4 , CoSO 4 , MnSO 4 Prepare nickel-cobalt-manganese mixed aqueous solution according to molar ratio Ni:Co:Mn=6:2:2, the total concentration is 0.15 mol / L, add 0.1g PVP (polyvinylpyrrolidone), add 0.5 g hexamethylenetetramine, Add 1g of ammonium bicarbonate, stir and dissolve to obtain a translucent solution. Stand still for 48 hours, aged at 80°C for 18 hours to obtain a khaki precipitate, evaporate and crystallize at 80°C, wash and dry to obtain a cubic ternary cathode material precursor. The shape is cubic, the particle size distribution is narrow, and the compacted density is 3.65 g / cm 3 , the specific surface area is 0.28m 2 / g.

Embodiment 3

[0026] NiSO 4 , CoSO 4 , MnSO 4 Prepare nickel-cobalt-manganese mixed aqueous solution according to the molar ratio Ni:Co:Mn=8:1:1, the total concentration is 0.5 mol / L, add 1 g SDS (sodium dodecylsulfosulfate), add 1 g hexamethylene Tetramine, add 2g of ammonium carbonate, stir and dissolve to obtain a translucent solution. Stand still for 12 hours, aged at 100°C for 12 hours to obtain a khaki precipitate, evaporate and crystallize at 100°C, wash and dry to obtain a cubic ternary cathode material precursor. The shape is cubic, the particle size distribution is narrow, and the compacted density is 3.75 g / cm 3 , with a specific surface area of 0.26 m 2 / g.

[0027] The tap densities and specific surface areas of the ternary cathode material precursors prepared in Examples 1 to 3 were measured respectively, and are listed in Table 1.

[0028] Table 1 is the physical and chemical performance data table of the embodiment of the present invention

[0029]

[0030] It ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com